26 Years+

Custom Service

Metal parts

Plastic parts

Rubber parts

Manufacture

首页 » About

Xiamen Goldcattle Industrial & Trade Co.,Ltd.

CNC / Molds / 3D Printing / Injection Molding / Stamping

A processing factory with 26 years of experience, providing customized part services such as mold, sheet metal, stamping, 3D printing, injection molding, etc.

We are a national grade high-tech enterprise which professionally speciallized in R&D and manufacture high precise injection parts, high precise machining parts and stamping parts . We provide total solution to customers including molding design and manufacture, parts mass production and assembly. As an OEM and ODM factory, we have a team of experienced and skillful industrial designers and engineers who are engaged in mold designing, manufacturing and CNC programming. With the principle of “high-quality, efficiency, honesty and service”, the aim of “sustainable operation, customers uppermost” and the good attitude of work and service, we are looking forward to building long-term and win-win business relationships with clients from all over the world.

The injection – molding customization service is carried out around the needs of customers. It includes the design, shaping, and functionality design of products. Mold manufacturing ensures product molding, injection – molding production realizes product creation, and there are also post – processing procedures such as trimming and assembly to create exclusive plastic products.

The injection – molding customization service is carried out around the needs of customers. It includes the design, shaping, and functionality design of products. Mold manufacturing ensures product molding, injection – molding production realizes product creation, and there are also post – processing procedures such as trimming and assembly to create exclusive plastic products.

The injection – molding customization service is carried out around the needs of customers. It includes the design, shaping, and functionality design of products. Mold manufacturing ensures product molding, injection – molding production realizes product creation, and there are also post – processing procedures such as trimming and assembly to create exclusive plastic products.

The injection – molding customization service is carried out around the needs of customers. It includes the design, shaping, and functionality design of products. Mold manufacturing ensures product molding, injection – molding production realizes product creation, and there are also post – processing procedures such as trimming and assembly to create exclusive plastic products.

The injection mold customization service starts with communication of requirements. Based on the product design plan, professional technologies are used to manufacture the mold. It includes mold design, material selection, processing and manufacturing, as well as debugging and optimization to ensure the accuracy and quality of the mold, and make it suitable for subsequent injection – molding production requirements.

The injection mold customization service starts with communication of requirements. Based on the product design plan, professional technologies are used to manufacture the mold. It includes mold design, material selection, processing and manufacturing, as well as debugging and optimization to ensure the accuracy and quality of the mold, and make it suitable for subsequent injection – molding production requirements.

The 3D printing customization service, according to the customer’s requirements, imports the 3D model data into the equipment. By layer – by – layer depositing materials such as plastics and metals, it can quickly manufacture products or models with complex shapes and personalized features. It covers aspects such as design and modeling, material selection, printing, and post – processing.

The 3D printing customization service, according to the customer’s requirements, imports the 3D model data into the equipment. By layer – by – layer depositing materials such as plastics and metals, it can quickly manufacture products or models with complex shapes and personalized features. It covers aspects such as design and modeling, material selection, printing, and post – processing.

The die – casting parts customization service starts from the customer’s needs. After drawing design and mold manufacturing, liquid or semi – liquid metal is pressed into the mold cavity at high speed under high pressure. After forming, post – processing such as cleaning and machining is carried out to provide customers with customized die – casting parts with high precision and high strength.

The die – casting parts customization service starts from the customer’s needs. After drawing design and mold manufacturing, liquid or semi – liquid metal is pressed into the mold cavity at high speed under high pressure. After forming, post – processing such as cleaning and machining is carried out to provide customers with customized die – casting parts with high precision and high strength.

Specialization / Professionalism / Concentration / Precision / Productivity

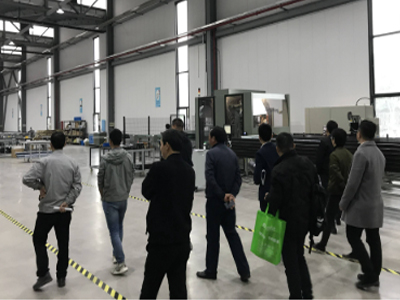

Factory building of over 1000 ㎡,

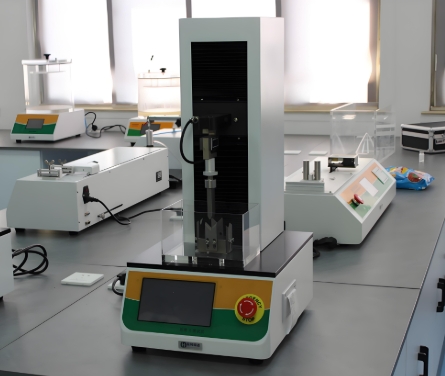

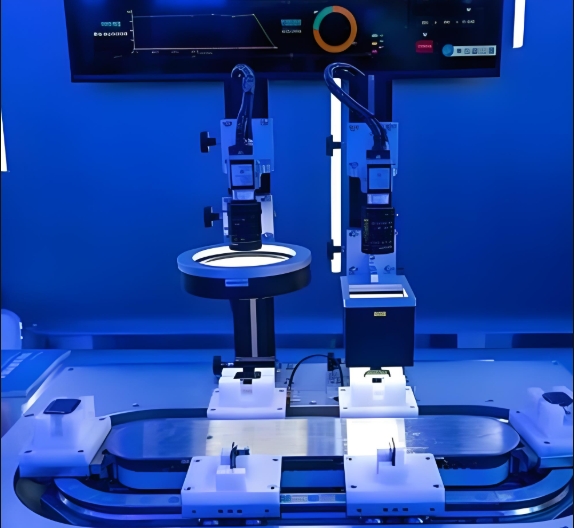

more than 100 processing equipment

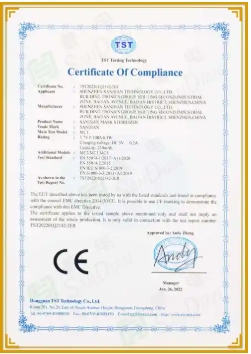

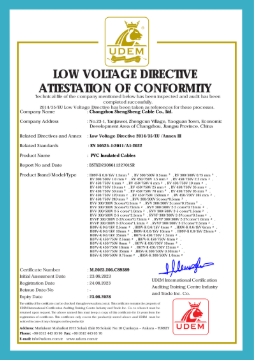

Provide professional product inspection reports and certificates according to customers’ requirements.

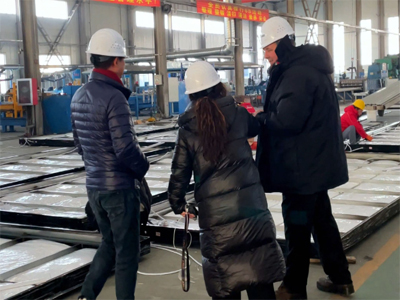

Our customers are all over the world. Every year, old customers bring new ones to visit our workshops.

The newly – introduced processing and inspection equipment ensures the quality of products.