Custom CNC Turning Milling Nylon POM ABS Plastic CNC Machining Parts

Place of Origin : Fujian, China

Brand Name : JSD

Model Number : CMP-314

Plastic Modling Type : Injection

Product name : Custom CNC Turning Milling Parts

Material : Nylon POM ABS Plastic

Color : Custom Color

Size : Customizable Size

Shape : Customized Shapes

Drawing Format : 2D/(PDF/CAD)3D(IGES/STEP)

Service : CNC Turning Milling

Certification : ISO9001

Application : broader

MOQ : 1 Piece

Description

1. Product Introduction

In the field of precision manufacturing today, we are proud to present to you custom CNC turning and milling nylon POM ABS plastic CNC processed parts. These parts are meticulously crafted through advanced numerical control technology and exquisite craftsmanship, aiming to meet your various needs for high-quality and high-precision plastic parts.

2. Customization Services

2.1 Personalized Customization: We know that each project has its unique requirements. Whether you need parts of specific shapes, sizes, and functions, or to match specific design specifications, our customization service can meet your needs. From the initial design to the final product, we work closely with you to ensure that every detail meets your expectations.

2.2 Professional Design Team: We have an experienced and innovative design team. They can understand your concept and use professional knowledge to transform it into feasible manufacturing solutions, providing you with the most optimized design suggestions.

3. Quality Assurance

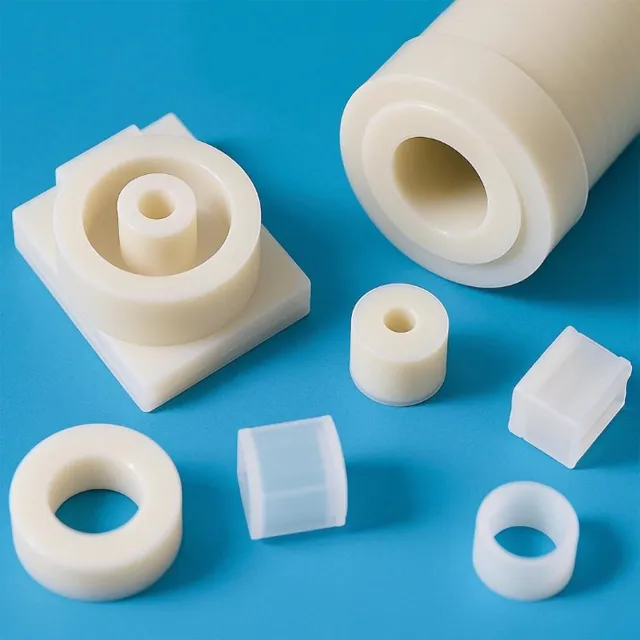

3.1 High-quality Raw Materials: Select high-quality plastic materials such as nylon, POM, ABS, etc., to ensure that the parts have excellent physical properties, chemical stability and wear resistance.

3.2 Strict Inspection Process: At every stage of production, strict quality inspections are carried out. From the incoming inspection of raw materials, to the dimensional measurement during the processing, to the comprehensive performance test of the finished products, we do not overlook any detail that may affect the quality.

3.3 Quality Certification: Our production process follows a strict quality management system, and the products comply with relevant international quality standards.

4. Exquisite Craftsmanship

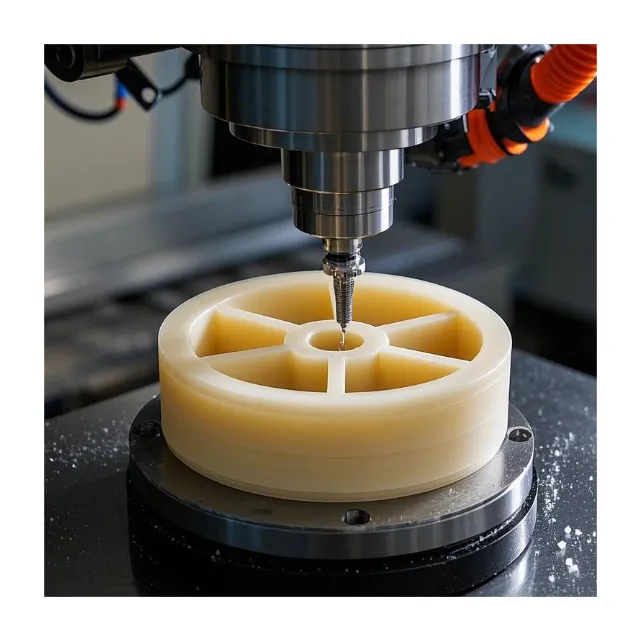

4.1 Advanced CNC Turning and Milling Technology: The most advanced computer numerical control turning and milling technology is adopted, which can achieve complex shapes and high-precision processing requirements. Whether it is inner holes, outer circles, threads, or complex curved surfaces and contours, we can process them precisely.

4.2 Fine Surface Treatment: By carefully adjusting the processing parameters and using appropriate tools, we can provide smooth and uniform surfaces for the parts, reducing friction and wear, and improving the service life and performance of the parts.

5. Advanced Processing Equipment

5.1 High-precision CNC Machine Tools: Equipped with multiple high-precision CNC turning and milling machine tools, with the characteristics of high speed, high precision and high stability, which can ensure the processing accuracy and consistency of the parts.

5.2 Intelligent Control System: The machine tools adopt advanced intelligent control systems, which can realize automatic programming and processing, improve production efficiency, and reduce human errors.

6. Product Parameters

6.1 Materials: Plastic materials such as nylon, POM (polyoxymethylene), ABS (acrylonitrile-butadiene-styrene copolymer), etc.

6.3 Shapes: Various complex shapes can be processed, such as cylinders, spheres, cones, irregular shapes, etc.

7. Customer Cases and Application Fields

Our custom parts are widely used in many fields such as automotive manufacturing, electronic equipment, medical devices, aerospace, mechanical engineering, etc., and have been highly recognized by customers. Here are some successful cases:

7.1 [Case One]: High-precision nylon parts provided for a certain automotive parts manufacturer, used in the sealing system of the automotive engine, effectively improving the performance and reliability of the engine.

7.2 [Case Two]: POM plastic parts processed for an electronic equipment manufacturer, used in the internal structural parts of the mobile phone shell, with good strength and wear resistance.

8. Purchase Process and After-sales Service

8.1 Purchase Process:

- Consultation: Contact our customer service team and describe your needs in detail.

- Quotation: We will provide you with an accurate quotation and delivery time based on your requirements.

- Place an Order: After confirming the quotation, sign the contract and place the order.

- Production: We carry out production and processing in accordance with the contract.

- Delivery: Deliver the products on time and provide relevant quality inspection reports.

8.2 After-sales Service:

- Quality Assurance: We provide a [specific duration] quality warranty service for the product quality. If there are any quality problems within the warranty period, we will replace or repair it for you free of charge.

- Technical Support: If you encounter any technical problems during use, our professional technical team will provide you with support and solutions at any time.

Choosing our custom CNC turning and milling nylon POM ABS plastic CNC processed parts means choosing high quality, high precision and professional services. Let’s join hands to create a bright future together!

—

Hope the above content is helpful to you. You can adjust and improve the content according to the actual situation. If you have other needs, such as more case introductions, detailed descriptions of the process, etc., please feel free to tell me.