What Are Custom Plastic Molds Anyway?

Let me tell you, these things are the backbone of the plastic processing industry! Custom plastic molds are precision tools that work with plastic molding machines to give your products the exact shape and dimensions you need.

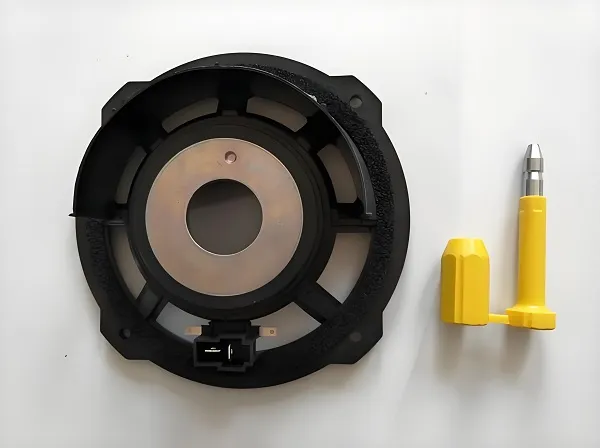

Bro, I’ve seen what these molds can do—from tiny electronic components to big automotive parts, they’re everywhere! And the best part? You can customize them to make pretty much any plastic product you can imagine.

The Basics You Need to Know

Definition & Core Purpose

Custom plastic molds are specialized tools used in compression molding, extrusion molding, injection molding, blow molding, and low-foam molding. They’re like the cookie cutters of the plastic world—but way more precise!

Where Are They Used?

- Automotive industry (bumpers, dashboards, interior parts)

- Home appliances (TV frames, washing machine components)

- Electronic communications (phone cases, computer parts)

- Daily necessities (toothbrushes, food containers, toys)

How Do They Work?

Here’s the deal: The mold gets clamped onto an injection molding machine, molten plastic gets injected into the cavity, it cools down and solidifies, then the mold opens and the product gets ejected. Rinse and repeat—simple as that!

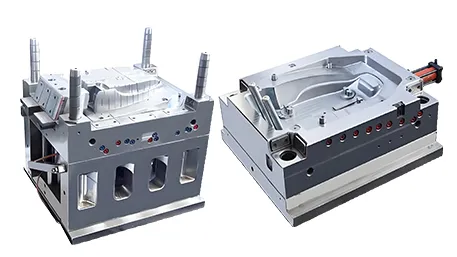

Anatomy of a Plastic Mold

Basic Structure

- Moving mold (mounted on the injection machine’s moving plate)

- Fixed mold (mounted on the injection machine’s fixed plate)

- Pouring system (main runner, cold slug well, manifold, gate)

- Molding parts (cavity, core, molding rods, exhaust ports)

- Temperature control system

- Ejection system

Materials Used

- Carbon structural steel (affordable, good machinability)

- Carbon tool steel (hard, wear-resistant)

- Alloy tool steel (excellent mechanical properties)

- High-speed steel (for high-temperature applications)

- Corrosion-resistant steel (for special environments)

Critical Process Parameters

HDPE & PP Injection Molding Parameters (For Reference Only)

| Parameter | HDPE | PP |

|---|---|---|

| Barrel Temperature (°C) | 200-240 | 220-240 |

| Mold Temperature (°C) | 20-60 | 20-70 |

| Injection Pressure (MPa) | 80-140 | 80-140 |

| Holding Pressure (%) | 30-60 | 30-60 |

| Shrinkage Rate (%) | 1.2-2.5 | 1.2-2.5 |

* These are general guidelines—actual parameters may vary based on specific product requirements and equipment.

Types of Plastic Molds

Injection Molds

The most common type! Used for making everything from bottle caps to car parts. Molten plastic is injected into the mold cavity under high pressure.

Extrusion Molds

Perfect for making continuous shapes like pipes, tubes, and profiles. Plastic is pushed through a die to create the desired cross-section.

Compression Molds

Great for thermosetting plastics. The material is placed in the mold cavity and then heated and pressed to form the final product.

Blow Molds

Used for making hollow products like bottles and containers. A parison (tube of plastic) is inflated inside the mold to take its shape.

How Custom Molds Are Made

Step-by-Step Manufacturing Process

- Mold Design: 3D modeling and mold flow analysis to ensure perfect results

- Material Selection: Choosing the right steel based on application requirements

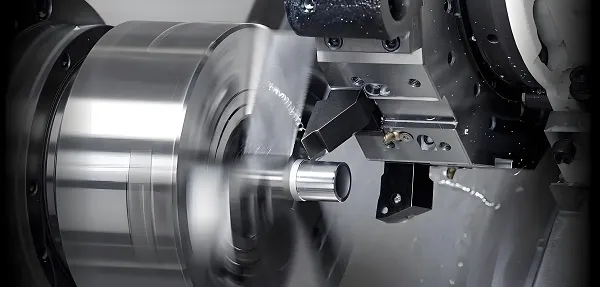

- Precision Machining: CNC machining, EDM, wire-cutting for accuracy

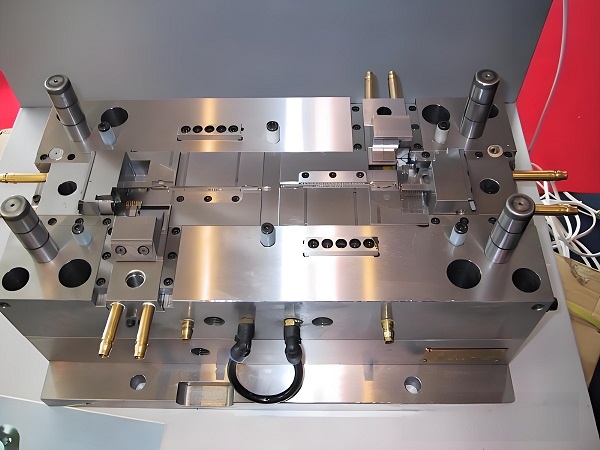

- Assembly & Debugging: Putting all the parts together and testing functionality

- Trial Molding: Testing with actual plastic to check for issues

- Optimization: Making adjustments based on trial results

- Final Inspection: Quality control checks before delivery

Quality Standards & Inspection

What We Check During Inspection

- Appearance: No cracks, scratches, or surface defects

- Dimensions: Tolerances within ±0.01mm for critical features

- Fit Precision: Smooth operation of moving parts

- Material Properties: Hardness testing (HRC 50-60 typical)

- Molding Performance: Consistent product quality over 100+ cycles

Industry Standards We Follow

International Standards

- ISO 9001: Quality management system

- ISO 13485: Medical device quality management

- ASTM D4169: Performance testing standards

Regional Standards

- FDA 21 CFR: Food contact materials

- EU REACH: Chemical safety regulations

- RoHS: Restriction of hazardous substances

Custom Mold Ordering Process

How to Get Your Custom Mold

FAQs About Custom Plastic Molds

How long does it take to make a custom mold?

It depends on complexity, but usually 4-8 weeks for simple molds and 8-16 weeks for complex ones. Trust me, good things take time—especially when precision matters!

How much does a custom mold cost?

Prices range from $1,000-$10,000+ depending on size, complexity, and material. Simple small molds start around $1,000, while large complex molds can cost $10,000 or more.

How to ensure mold quality?

We use high-precision CNC machines, strict quality control at every step, and trial molding before delivery. Plus, we provide detailed inspection reports—no surprises!

What materials can I choose from?

We offer carbon steel, alloy steel, stainless steel, and more. Let us know your application requirements, and we’ll recommend the best material for the job.

How to maintain plastic molds?

Regular cleaning, proper lubrication, and storage in a dry environment are key. Also, don’t forget to inspect molds regularly for wear and tear—catch issues early!

Cost Breakdown

What Affects the Price?

Design & Engineering

- 3D modeling: $500-$2,000

- Mold flow analysis: $300-$1,000

- Design optimization: $200-$800

Materials

- Carbon steel: $2-$5 per kg

- Alloy steel: $5-$15 per kg

- Stainless steel: $10-$25 per kg

Processing Costs

- CNC machining: $100-$300 per hour

- EDM/wire-cutting: $80-$200 per hour

- Polishing & finishing: $50-$150 per hour

Quality Control

- Inspection equipment: $200-$800

- Trial molding: $500-$1,500

- Documentation: $100-$300

Ready to Start Your Project?

Custom plastic molds are essential for bringing your product ideas to life in the plastic manufacturing world.

Whether you’re making consumer products, industrial components, or medical devices, the right mold can make all the difference in quality and efficiency.

Trust me, investing in a high-quality custom mold will save you time, money, and headaches in the long run!