With the rapid development of the automotive industry, injection molding technology is increasingly widely used in the manufacture of automotive parts. As an important part of automobile manufacturing, the technical level and production efficiency of customized automobile injection molded parts are directly related to the overall quality and market competitiveness of automobiles. The purpose of this report is to analyze the current situation, technical characteristics, development trend and challenges faced by the customized automotive injection molding parts industry in depth, and to provide reference for related enterprises.

1. Injection molding technology characteristics

High precision: modern injection molding technology is capable of achieving micron-level precision to meet the high requirements of automotive parts in terms of size and shape.

Lightweight: the use of high-strength, low-density plastic materials, through the optimization of the design to reduce the weight of parts, improve fuel efficiency.

Complex structure: injection molding technology can manufacture parts with complex internal structure and surface texture to meet the diverse needs of automotive design.

Automation and Intelligence: The injection molding production line is highly automated, combining intelligent technologies such as the Internet of Things and big data to achieve real-time monitoring and optimization of the production process.

Application Areas

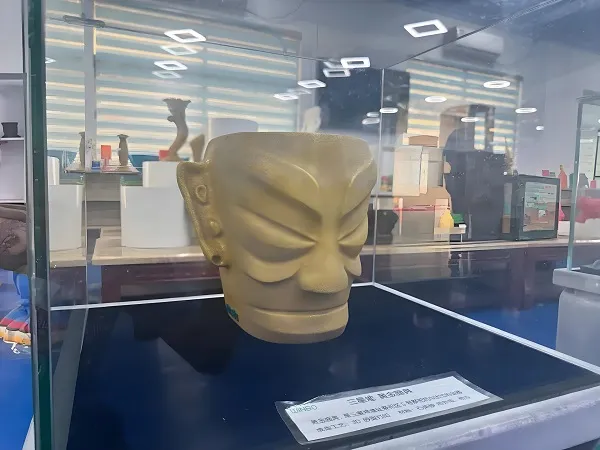

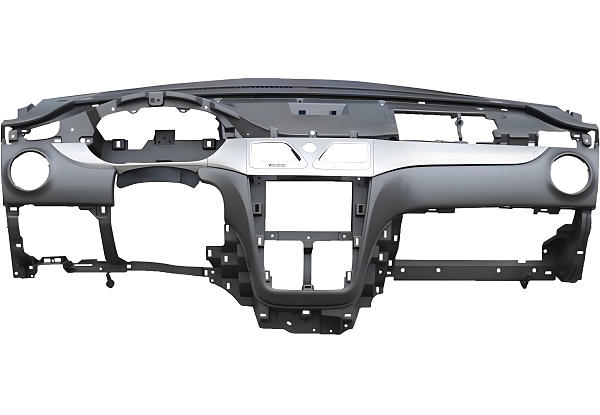

Customized automotive injection molded parts are widely used in a variety of fields such as automotive interior and exterior parts, functional parts, structural parts, such as bumpers, instrument panels, door panels, seat frames and so on.

2. Injection molding technology development trend

2.1 Material Innovation

New plastic materials such as bio-based plastics, high-performance engineering plastics, etc. continue to emerge, providing more options for injection molded parts. These materials have better mechanical properties, heat resistance, weather resistance and environmental protection.

2.2 Process optimization

Multi-component injection molding: to achieve different materials in the same mold at the same time injection molding, improve the functionality and aesthetics of the parts.

Micro-injection molding: suitable for manufacturing tiny parts, such as sensors, connectors, etc., to meet the needs of automotive electronics and intelligence.

Rapid thermal cycle injection molding: shorten the injection cycle, improve production efficiency, while maintaining stable part quality.

2.3 Digitalization and Intelligent

CAD/CAE/CAM Integration: Realize the digital process from design to manufacturing, improve design efficiency and manufacturing accuracy.

Intelligent Manufacturing: Combining technologies such as Internet of Things, big data and artificial intelligence to realize intelligent management and optimization of the injection molding production line.

2.4 Environmental protection and sustainable development

The production process of injection molded parts focuses on energy saving and emission reduction and waste recycling, promoting the industry to develop in the direction of green and low-carbon.

3. Customized automotive injection molding parts service process

3.1 Demand Analysis

Step Description:

Communicate deeply with customers to clarify their customization needs, including the size, shape, material requirements and performance parameters of the parts.

Analyze the use, working environment and expected life of the parts in order to provide a basis for subsequent design.

3.2 Design Development

Step Description:

Perform 3D modeling and detailed design of the part according to customer requirements.

Consider material fluidity, shrinkage, mold structure and other factors during the design process to ensure the manufacturability of the part.

Complete design drawings and process documents, including injection molding process parameters, mold structure drawings, etc.

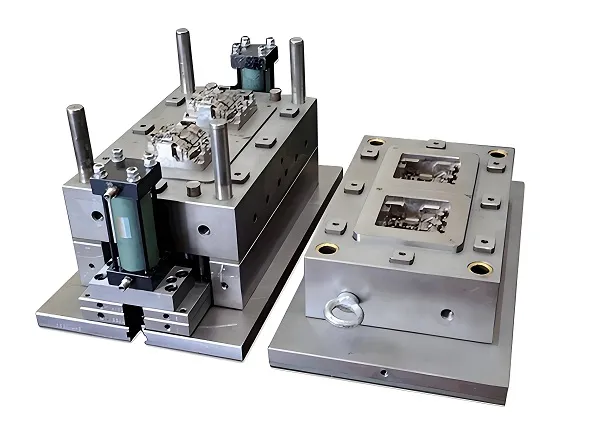

3.3 Mold Manufacturing

Step Description:

According to the design drawings, manufacture the injection mold. Mold manufacturing includes mold design, material selection, processing and manufacturing, assembly and debugging steps.

In the process of mold manufacturing, the processing precision and assembly quality should be strictly controlled to ensure the precision and life of the mold.

3.4 Injection molding production

Step Description:

The plastic raw material is added into the injection molding machine and injected into the mold cavity after heating and plasticizing.

After cooling and curing in the mold, open the mold and take out the parts.

Preliminary inspection of the part is carried out to reject non-conforming products.

3.5 Quality Control

Step Description:

Conduct a comprehensive inspection of the injection molded parts, including dimensions, appearance, performance and other aspects.

Adopt advanced testing equipment and methods to ensure that the quality of parts meets customer requirements and industry standards.

Analyze the reasons for non-conforming products and take corresponding measures for improvement.

3.6 Delivery and after-sales

Step Description:

Deliver qualified injection molded parts to customers and provide necessary technical support and after-sales service.

Track the use of customers and collect feedbacks for continuous improvement of products and services.

Automotive injection molded parts FAQ

1. What are automotive injection molded parts?

A: Automotive injection molded parts are automotive parts produced through the injection molding process. Injection molding is a method of injecting molten plastic into a mold, cooling and curing it to obtain a part of the desired shape and size. These parts are widely used in a variety of applications such as automotive interior and exterior, functional and structural parts.

2. What are the advantages of injection molding?

A: Injection molding has the advantages of high productivity, low cost, the ability to manufacture complex shaped parts, and high material utilization. In addition, injection molded parts also have good dimensional stability and surface quality, to meet the requirements of automobile manufacturing on the accuracy and appearance of parts.

3. What are the materials for automotive injection molded parts?

A: Materials commonly used for automotive injection molded parts include ABS (Acrylonitrile Butadiene Styrene Copolymer), PP (Polypropylene), PC (Polycarbonate), PA (Nylon) and so on. These materials have different mechanical properties, heat resistance, weather resistance and processing performance, according to the specific requirements of the parts to choose the right material.

4. injection mold design on the quality of parts?

A: The design of the injection mold directly affects the quality of the parts. Reasonable mold design can ensure that the plastic melt in the mold uniform flow, rapid cooling, so as to get the accurate size, smooth surface parts. Factors such as the precision, structure, and cooling system of the mold all affect the quality of the injection molded part.