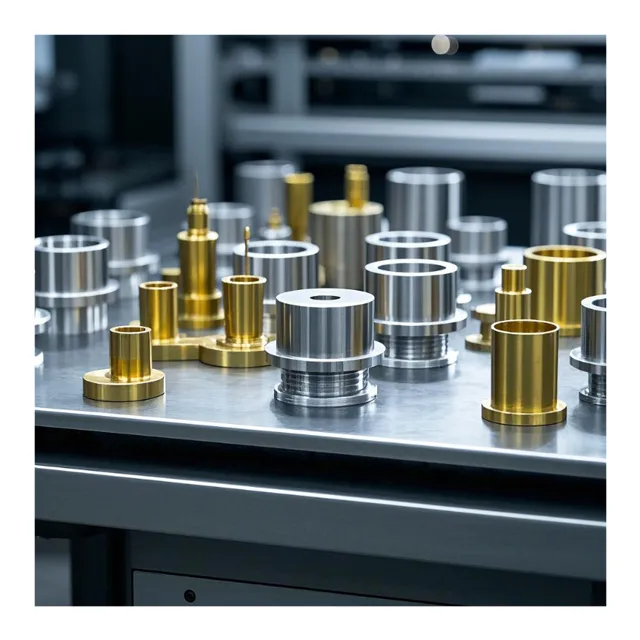

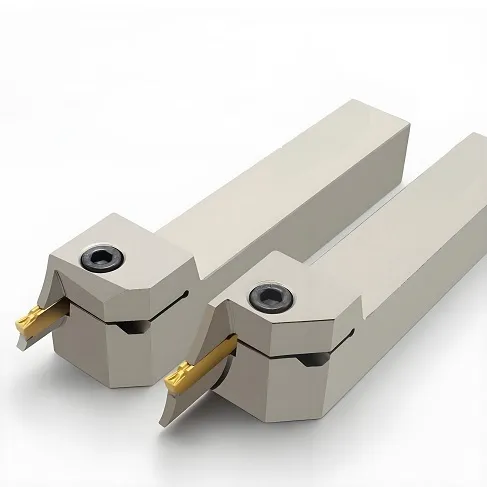

Processing materials: Stainless steel (304/316L), aluminum alloy (6061/7075), brass (H59/H62), titanium alloy (Gr5/Ti6Al4V), carbon steel, tool steel.

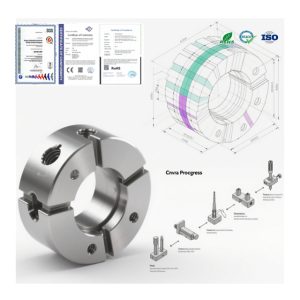

Processing accuracy: ±0.01mm (conventional) / ±0.002mm (for high – precision requirements).

Processing types: Turning, milling, drilling, wire – cutting, laser processing.

Surface treatments: Anodizing, electroplating (zinc/chromium), sandblasting, polishing, powder coating.

Application fields: Auto parts (engine/transmission parts), motorcycle accessories, aerospace precision parts, industrial equipment components.

Certification standard: ISO 9001 (default).

MOQ: Minimum order quantity is 1 piece (sample customization is supported).

Delivery cycle: 5 – 15 days (conventional).

Packaging method: Shock – proof foam + PP bag (inner layer), customized wooden box/carton (outer layer).