In the modern manufacturing field, aluminum has become one of the core materials for CNC machining due to its high machinability, lightweight nature, and excellent cost-effectiveness. Whether it is precision components for aerospace or housing structures for consumer electronics, aluminum CNC machining plays a crucial role.

As a solution provider in the relevant field, XIAMEN GOLDCATTLE provides end-to-end support for aluminum CNC machining from design and simulation to production through its service system, helping enterprises achieve high-precision and efficient manufacturing goals.

this article will explain the core knowledge of aluminum CNC machining in detail and interpret how to solve industry pain points through technical solutions.

I. Why Has Aluminum CNC Machining Become a “Hot Commodity” in the Manufacturing Industry?

Aluminum is widely used in CNC machining due to its unique material properties, and these advantages also make it the first choice for lightweight and cost-effective manufacturing needs:

- High Machinability: The density of aluminum is only about 1/3 that of steel, and its machining speed is 3-4 times faster than that of steel, which can significantly shorten the part production cycle, reduce tool wear, and lower machining costs;

- Balance of Lightweight and High Strength: Although pure aluminum has low strength, through alloying (e.g., adding elements such as copper, magnesium, and lithium), it can form materials with both lightweight and high mechanical properties, meeting the needs of weight-sensitive fields such as aerospace and automotive;

- Excellent Corrosion Resistance: A dense oxide film is easily formed on the surface of aluminum, which can resist corrosion in most environments without additional coatings. If used outdoors or in harsh working conditions, the protective ability can be further improved through surface treatment;

- Environmental Protection and Sustainability: Aluminum is a 100% recyclable metal, and the energy consumption of the recycling process is only 5% of that of primary aluminum smelting, which conforms to the concept of green manufacturing and helps enterprises achieve sustainable development;

- Multi-scenario Adaptability: From lightweight containers for food packaging to high-temperature resistant components for aero-engines, aluminum and aluminum alloys can meet diverse needs through different CNC processes, covering consumer, industrial, high-end manufacturing and other fields.

II. Aluminum from Ore to CNC Machining Raw Material: Completing the “Transformation” in Two Steps

Aluminum does not exist in metallic form naturally. Its production requires two core steps: “alumina extraction” and “primary aluminum smelting”, which are also the basis for ensuring the quality of subsequent CNC machining materials:

1. Extracting Alumina from Bauxite (Bayer Process)

More than 90% of the world’s alumina is produced using the Bayer Process, a technology invented by Austrian chemist Carl Josef Bayer in the late 19th century and still the mainstream technology today:

- Step 1: Crush bauxite (containing 30%-60% alumina) into fine powder, mix it with water and caustic soda, then heat the mixture. The caustic soda dissolves the alumina to form a filterable solution;

- Step 2: Add aluminum hydroxide crystals (“seed crystals”) to the solution to promote the precipitation of alumina in the form of aluminum hydroxide;

- Step 3: Heat and dry the precipitated aluminum hydroxide to finally obtain high-purity alumina (Al₂O₃).

2. Electrolytic Smelting of Alumina into Primary Aluminum

Alumina needs to be converted into processable primary aluminum through electrolysis, and the process is as follows:

- Dissolve alumina in a fluoride bath (e.g., cryolite), pass a strong electric current for electrolysis to decompose alumina into metallic aluminum and oxygen;

- Collect the liquid metallic aluminum, mix it with recycled aluminum materials, send it to a furnace for melting, and then form it into raw material forms required for CNC machining (such as sheets, billets, rods, tubes, profiles) through casting or extrusion.

III. What is CNC Machining? The “Digital Brain” of Precision Manufacturing

CNC (Computer Numerical Control) machining is an advanced manufacturing technology that combines traditional mechanical machining with a digital control system, and it is also the core method for producing precision aluminum parts:

1. Core Advantages of CNC Machining

Compared with manual machining, CNC technology controls the movement of equipment through computer programs and has three irreplaceable advantages:

- Ultra-high Precision: The error can be controlled at the micron level (e.g., adapting to the machining precision supported by the enterprise), meeting the strict requirements for dimensional consistency in fields such as aerospace and medical equipment;

- High Efficiency and Stability: It can operate continuously for 24 hours, avoiding error fluctuations caused by manual operations, while reducing material waste and improving production efficiency;

- High Design Freedom: It can realize complex structures (such as curved surfaces, hollowing, multi-cavity features) that are difficult to achieve with manual machining, adapting to the needs of personalized and customized parts.

2. Common Equipment for Aluminum CNC Machining

The enterprise’s service system covers mainstream CNC machining equipment, and suitable solutions can be selected according to the structure and precision requirements of aluminum parts:

- CNC Milling Machines/Machining Centers: The most commonly used equipment, which performs milling, drilling, boring, etc., on fixed aluminum materials through rotating cutting tools. It supports 2-12 axis configurations (3-5 axes are mainstream) and is suitable for complex three-dimensional parts;

- CNC Lathes/CNC Turning Centers: Realize turning, threading, and groove machining by rotating aluminum materials and fixing cutting tools, suitable for shaft-shaped, disc-shaped and other rotationally symmetric parts;

- CNC Plasma Cutters: Use high-temperature plasma arcs to melt aluminum materials (capable of cutting up to 6 inches thick), suitable for rapid cutting of medium and thick aluminum plates;

- CNC Laser Cutters: Melt/vaporize aluminum materials through high-energy laser beams, with higher precision than plasma cutting, especially suitable for fine cutting of thin aluminum plates;

- CNC Water Jet Cutters: Cut aluminum materials with high-pressure water (which can be mixed with abrasives), without thermal deformation, suitable for aluminum parts that are heat-sensitive or prone to deformation.

IV. Common Aluminum Alloys for CNC Machining: Choose the Right “Material Partner” According to Needs

Pure aluminum has low strength and cannot meet most industrial scenarios, so aluminum alloys are mainly used in aluminum CNC machining. According to production processes and properties, mainstream alloys can be divided into three categories, and the enterprise can match alloys with machining solutions through simulation tools in the design stage:

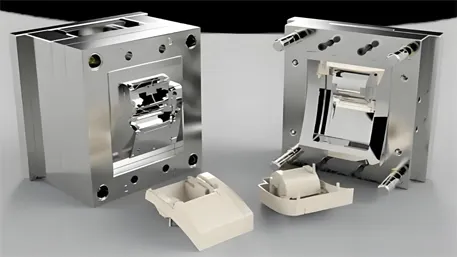

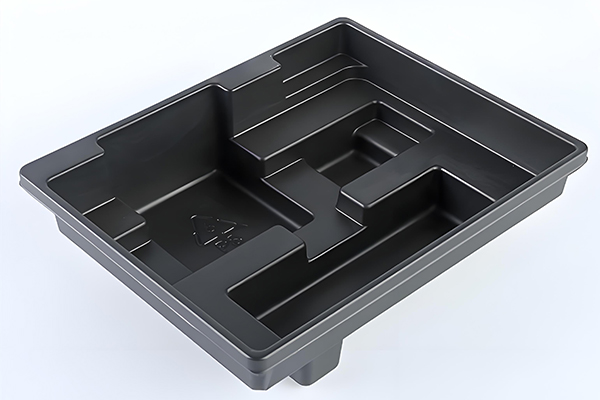

1. Cast Aluminum Alloys

- Production Process: Pour molten aluminum alloy into a mold and cool it to form;

- Core Advantages: Low cost, flexible forming, capable of manufacturing complex shapes, and excellent high-temperature resistance;

- Typical Applications: Automotive engine parts, housings, kitchenware, mechanical accessories (accounting for 2/3 of aluminum used in automobiles);

- Points to Note: Lower tensile strength than wrought aluminum alloys, slightly poor machinability, and greater wear on cutting tools.

2. Aluminum-Lithium (Al-Li) Alloys

- Core Characteristics: Lithium is the lightest metal, and Al-Li alloys are 10%-15% lighter than pure aluminum with higher strength;

- Typical Applications: Aerospace field (e.g., wing skins, fuselage structures, rocket components), racing cars;

- Points to Note: Low machinability, weak fracture toughness, and high cost due to small production volume. The enterprise’s simulation tools are needed to optimize machining parameters.

3. Wrought Aluminum Alloys

- Production Process: Form molten aluminum into billets, and then shape these blocks through rolling, forging, extrusion and other solid-state forming processes;

- Core Advantages: Excellent mechanical properties, good structural integrity, strong machinability, and high surface finish, making it the “main alloy” for aluminum CNC machining;

- Typical Applications: Aerospace structural parts, consumer electronics housings (e.g., mobile phones, laptops), building profiles, automotive lightweight components.

V. Aluminum vs. Steel CNC Machining: Comparison in 5 Dimensions to Choose the Right Material and Avoid Detours

Aluminum and steel are the two core metals in CNC machining. The enterprise helps enterprises make choices according to needs through industry solutions, and the key comparison dimensions are as follows:

| Comparison Dimension | Aluminum CNC Machining | Steel CNC Machining |

|---|---|---|

| Cost | Aluminum alloys (except high-end models) are more expensive than carbon steel but cheaper than stainless steel | Carbon steel has low cost, while stainless steel has high cost |

| Corrosion Resistance | Natural corrosion resistance (oxide film) without additional coatings | Carbon steel needs coating for rust prevention; stainless steel has corrosion resistance but high cost |

| Weight | 2-3 times lighter than steel, suitable for lightweight needs | Heavy weight, suitable for scenarios where weight is not sensitive |

| Strength | Higher strength after alloying, but generally lower than steel | High strength, strong deformation resistance, and scratch-resistant surface |

| Machinability | Fast speed (3-4 times that of steel), fast cooling, and low tool wear | Slow speed, requiring more coolant, and high tool loss |

VI. End-to-End “Enabler”: Technical Support for Aluminum CNC Machining

Whether it is the design, simulation, production or service of aluminum CNC machining, XIAMEN GOLDCATTLE provides a one-stop solution through its service system to solve the pain points of enterprises from “drawing to finished product”:

1. Design Stage: Precise Modeling to Avoid Machining Risks in Advance

- Use professional 3D design software to complete the refined modeling of aluminum parts, supporting complex structure design;

- Conduct machining simulation through simulation tools to predict the deformation of aluminum materials during cutting and cooling, and optimize process parameters (such as cutting speed, feed rate).

2. Production Stage: On-Demand Manufacturing to Flexibly Adapt to Batch Needs

- Its service system integrates CNC machining, 3D printing, injection molding and other services, supporting “On-Demand Manufacturing” and rapid prototyping (Prototyping);

- Provide supplier matching function: connect with high-quality CNC machining factories to quickly obtain multiple quotes and shorten the production cycle.

3. Industry Solutions: Focus on Vertical Field Needs

The service system covers core industries of aluminum CNC machining and provides customized solutions:

- Aerospace: Focus on Al-Li alloy machining, combined with virtual twin technology to ensure part precision and lightweight;

- Automotive/Transportation: Focus on the lightweight of aluminum parts, optimize the machining process of cast/wrought aluminum alloys, and reduce the weight of the whole vehicle;

- High-Tech/Consumer Electronics: Realize the lightweight and fine appearance of aluminum housings through laser cutting and precision milling;

- Medical: Use heat-free deformation processes such as water jet cutting to machine aluminum parts for medical equipment and ensure biocompatibility.

4. Support and Resources: Full-Cycle Guarantee of Machining Efficiency

- Training and Certification: Provide CNC machining skill training and certification programs to improve team capabilities;

- Technical Support: Cover documents, software downloads, and knowledge bases to solve technical problems in machining;

- Sustainability: Help enterprises achieve environmental protection goals through aluminum recycling and green machining solutions.

VII. How to Launch an Aluminum CNC Machining Project? Three Steps to Facilitate Implementation

- Clarify Needs: Determine the structure, precision, batch, and application scenario of aluminum parts, and complete the design or upload drawings through relevant platforms;

- Select Solutions: Select CNC machining equipment (such as milling machines, laser cutting), match aluminum alloy types through the service system, and obtain instant quotes;

- Implement Production: Connect with suppliers to complete machining, and use simulation tools to monitor the production process to ensure part quality meets standards.

Whether it is a manufacturing novice or an experienced enterprise in the industry, through professional aluminum CNC machining solutions, efficient collaboration of “design-simulation-production” can be achieved, reducing costs and improving precision. For more details, you can explore the relevant service system or contact the team to obtain customized demonstrations, making aluminum CNC machining simpler and more efficient!