Keywords: 3D Reverse Scanning, Hot Press Molding, Ergonomic Simulation

“I want a sci – fi dashboard cover with an LCD screen like in ‘Fast & Furious’. Can you make it?” – This is the most common demand from car – modification enthusiasts.

- Hand – held blue – light scanner (accuracy ±0.03mm) can obtain the contour of the original vehicle’s dashboard in 10 minutes and automatically generate a CAD model, not even missing the chamfer angle of the air – conditioning outlet.

- LiDAR surveys the entire vehicle’s center console to ensure that the gap between the modified part and the original vehicle is ≤0.5mm, eliminating the risk of abnormal noise.

- Embed an aluminum – alloy skeleton (thickness 1.2mm) inside the cover to support a 10.1 – inch touch screen, reducing weight by 40% compared to traditional plastic brackets.

- An e – sports – style cover with an active heat – dissipation air duct, equipped with 4 micro – fans (noise < 25dB), solves the problem of heat generation of high – power screens.

Case: The carbon – fiber dashboard cover customized for a Tesla Model 3 owner integrates an OLED vehicle condition display screen. It reads data through the CAN bus, increasing the tidiness by 200% compared to an external display.

Keywords: IMD Film, Aviation Aluminum – Magnesium Alloy, Bio – based Plastic

“Will it deform in the summer sun? Will there be an odor when the heater is turned on in winter?” – Materials are the key to success.

| Material Type |

Feature Comparison |

Applicable Scenarios |

| ABS + PC Alloy |

Low cost (¥80/kg), easy to spray – paint, but prone to yellowing after long – term exposure to the sun |

Economical modifications |

| IMD Film |

Surface hardness of 3H, patterns never fade, and can create a three – dimensional tactile texture |

High – end brand original – style replicas |

| Forged Carbon Fiber |

Tensile strength of 700MPa, thickness can reach 2mm, but the cost is as high as ¥1500/kg |

Supercar racing style |

| Polylactic Acid (PLA) |

Biodegradable material, carbon emissions 60% lower than ABS, but heat – resistant only up to 80°C |

Environment – friendly theme modifications |

Pitfall Warning: A car owner customized a dashboard cover with acrylic, and the screen sank due to softening at high temperatures in summer. Be sure to choose materials with a heat – resistance of > 100°C!

- Demand Confirmation: Determine whether it is an “original – factory upgrade” or a “cyber – punk style”

- Structural Design: Use CATIA to analyze the load – bearing capacity of the cover (a ribbed design is required for a ≥5kg display screen)

- Mold Development: Five – axis precision – carved aluminum mold (starting from ¥30,000) or silicone replication mold (¥5000, suitable for small – batch production)

- Trial – fitting Verification: Road – test the 3D – printed trial – fitting part for 2000 kilometers to detect the probability of abnormal noise under bumpy road conditions

- Mass – production Quality Inspection: Randomly select 3 pieces from each batch and conduct a 72 – hour cyclic test in an environmental chamber at – 30°C ~ 110°C

Lesson Learned: A factory skipped the environmental test and directly shipped the products. As a result, the covers cracked in winter for northern customers, and the factory had to pay 300,000 yuan in compensation!

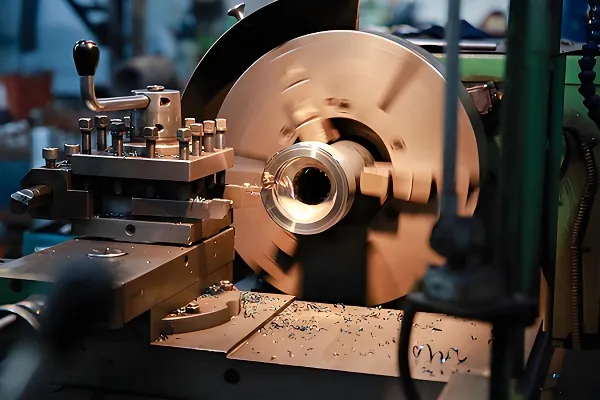

- 2000 – ton hot press: Permanently combines the IMD film with the substrate at 165°C/50MPa pressure, with a finished – product yield rate of 99.7%

- Six – axis laser engraving machine: Carves a 0.1mm – deep track pattern on the carbon – fiber surface, 20 times faster than manual polishing

- Dust – free spray – painting workshop: Equipped with a constant – temperature and – humidity system (temperature 23 ± 2°C, humidity 50% ± 5%) to ensure a dust – free paint surface

Industry Truth: 90% of “carbon – fiber” dashboard covers are actually water – transferred imitation patterns. Burn it with a lighter, and genuine carbon fiber won’t blister!

- Anti – aging Test: Simulate 5 – year sunlight exposure in a xenon – lamp aging machine (equivalent to 10 years of real – world use), with a color difference ΔE ≤ 1.5

- Volatile Substance Detection: VOC emissions < 50μg/m³ (the national standard requires < 200μg/m³), ensuring a safe ride for pregnant women and children

- Structural Strength: Use a 50 – kg counterweight to simulate human impact during emergency braking, with a cover deformation of ≤ 0.3mm

Data Speaks: The dashboard covers we supply to Porsche modification shops have passed 100,000 glove – box opening and closing tests in the German TÜV laboratory (far exceeding the industry standard of 50,000 times).

- Nano – injection molding: Directly inject and coat TPU soft rubber on the aluminum – alloy skeleton, eliminating the risk of delamination in traditional gluing processes

- Magnetron Sputtering Coating: Deposit a mobile – phone – grade AG anti – glare film layer, reducing the reflectivity from 8% to 3%, making night driving safer

- Olfactory Customization: Add micro – capsule perfume to the ABS raw material, and a light touch on the surface will release a delicate woody fragrance (lasting for more than 3 years)

Cutting – edge Technology Alert: The “tactile temperature – changing coating” under trial can reveal hidden patterns in the contact area when a finger swipes across the cover surface!

Price Composition Example (Forged Carbon Fiber + OLED Screen Integrated Version)

| Project |

Proportion |

Detailed Description |

| Materials |

35% |

2K carbon fabric + OLED screen + control module |

| Mold |

20% |

Five – axis CNC processing cost |

| Labor |

15% |

Technician’s hourly wage is ¥150, and it takes 16 hours |

| Inspection |

10% |

Electromagnetic compatibility + high – and low – temperature cycle tests |

| Profit |

20% |

|

Cost – saving Tips:

- Choose the water – transfer printing imitation carbon – fiber process, and the cost can be reduced by 80% directly.

- Order more than 5 pieces in a group, and the unit price can be reduced by 40% after sharing the mold cost.

Personalization Option Menu:

- Basic Version (+¥0): 10 standard colors available, delivered in 7 days

- Advanced Version (+¥800): Laser – engrave signature / team logo

- Flagship Version (+¥3500):

- Touch – sensitive ambient light (changes color with vehicle speed)

- Wireless charging module (supports 15W fast charging)

- Voice assistant wake – up button (compatible with Siri / Xiaoai Tongxue)

Immersive Experience: Preview the installation effect through AR glasses, and adjust 20 parameters such as the air – outlet angle and screen tilt.

- Q1: Will modifying the dashboard cover affect the deployment of the airbag?

- The airbag deployment area (usually marked as AIRBAG) must be avoided.

- Our design will reserve an airbag blasting guide groove to ensure that the deployment path is the same as the original factory.

- Q2: Can it be compatible with the original vehicle’s on – board computer display?

- Three solutions are supported:

- Retain the original screen (leave a window when the cover is molded).

- Transplant the original screen (the host model needs to be provided).

- Install an Android – system secondary screen (recommend the version with the Snapdragon 6125 chip).

- Q3: Will it crack in winter in the north?

- Use low – temperature modified PP materials (cold – resistant to – 40°C).

- In extreme regions, it is recommended to choose a carbon – fiber + Kevlar mixed – weave material (with a coefficient of thermal expansion close to that of steel).

- Q4: How to clean and maintain it?

- For suede – like materials: Use a neutral foam cleaner and a soft brush.

- For piano – Baking finish surfaces: Wax with a silica – containing coating agent once a month.

- For forged carbon fiber: No special maintenance is required. Avoid using corrosive solvents.

- Q5: What procedures are required to be legal on the road?

- In China:

- Do not block the speedometer / fault indicator light.

- Retain the original vehicle’s safety warning signs.

- In Europe and the US:

- In the EU, it needs to pass the E – Mark certification (light reflectivity test).

- In the US, it needs to comply with FMVSS 101 (control visibility standard).

In an era where even the steering wheel can be voice – controlled, the dashboard cover is no longer just a simple dust – cover. It is the car owner’s personal signature, the engineer’s micro – laboratory, and a witness to the evolution of the car from a tool to a companion. When you caress the exquisitely polished curves in the dead of night, you may feel that the best modifications are always a dialogue between the car and the owner born out of love.