Bro, Let’s Talk About REAL Thermal Management!

Alright listen up, if you’re dealing with electronics that run HOT, you NEED to get serious about heat sinks.

I’ve messed around with all kinds of cooling solutions, and let me tell you – aluminum profile CNC machining is WHERE IT’S AT!

This isn’t just about “cooling stuff down” – it’s about making sure your electronics SURVIVE and PERFORM at their best.

Pro tip: I once had a client who skimped on heat sinks and lost $50k in equipment. DON’T BE THAT GUY!

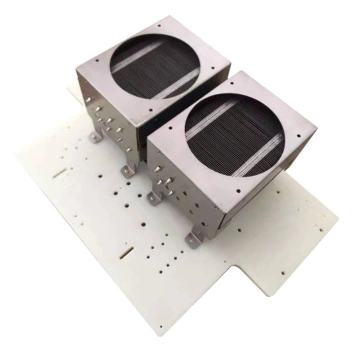

Check out these precision CNC machined heat sinks – the detail is INSANE!

Materials: The Secret Sauce (From Someone Who’s Tested Them All)

6061-T6 Aluminum (My Go-To Material)

Why I Love This Stuff:

- Thermal Conductivity: 200 W/m·K – not the absolute best, but MORE than enough for 95% of applications

- Strength: Ultimate tensile strength 310 MPa – this stuff doesn’t bend easily!

- Corrosion Resistance: Excellent – perfect for outdoor or harsh environments

- Machinability: 8/10 – cuts like butter with the right tools

- Cost: Mid-range – great balance of performance and budget

Best For:

High-performance LED lighting, CPU coolers, power electronics, automotive components – basically anything that needs to dissipate serious heat!

6063-T5 Aluminum (The Budget Champion)

When to Use This:

- Thermal Conductivity: 160-180 W/m·K – slightly lower than 6061, but still great

- Strength: Ultimate tensile strength 180 MPa – not as strong, but works for most cases

- Extrudability: 10/10 – this stuff was MADE for extrusion profiles

- Surface Finish: Amazing – perfect for anodizing and aesthetics

- Cost: Lower – saves money without sacrificing too much performance

Best For:

Consumer electronics, LED strips, basic heat sinks, decorative applications – when you want good performance at a great price!

Material Showdown: 6061 vs 6063 (The Real Numbers)

Manufacturing Process: From Raw Material to Finished Product

Extrusion Process (The First Step)

Billet Preparation

Raw aluminum is cut into 6-12 meter billets. These babies are heated to 450-500°C for extrusion. I’ve seen billets that weigh over 100kg – heavy stuff!

Hot Extrusion

The heated billet is pushed through a steel die at 1000-5000 tons of pressure. This is where the magic happens – the profile takes shape!

Quenching & Aging

The extruded profile is rapidly cooled (quenched) with water, then aged at 120-180°C for 6-24 hours. This gives it that T5/T6 hardness we love!

CNC Machining (The Precision Part)

Precision Cutting

The extruded profile is cut to exact length using CNC saws. Tolerance? ±0.1mm – that’s precise enough for rocket parts!

Milling & Drilling

CNC machines create fins, grooves, and mounting holes. We use 4-5 axis machines for complex geometries. I’ve seen machines that can mill 0.1mm features – INSANE precision!

Surface Finishing

Deburring, sandblasting, and anodizing. The surface finish can affect thermal performance by up to 15% – don’t skip this step!

Quality Control Checkpoints:

Dimensional Inspection:

- Profile dimensions: ±0.1mm tolerance

- Fin thickness: ±0.05mm precision

- Hole positions: ±0.02mm accuracy

- Surface flatness: ≤0.1mm per meter

Material Testing:

- Hardness testing: 90-95 HRB for 6061-T6

- Tensile strength verification

- Thermal conductivity measurement

- Corrosion resistance testing

Technical Specs & Performance Data (The Real Numbers)

Design Parameters (For Your Reference Only!)

Pro Design Tip:

The aspect ratio (fin height to spacing) is CRITICAL! If it’s too high, air can’t flow between the fins and cooling efficiency drops by 30-50%. Trust me, I’ve tested this!

Thermal Performance Data (Test Results)

Testing Conditions:

All tests conducted at 25°C ambient temperature, 1m/s airflow, with thermal interface material (TIM) of 0.1mm thickness. Results may vary in real-world applications!

Industry Standards & Certifications (The Stuff That Matters)

Material Standards

- ASTM B221: Standard specification for aluminum and aluminum-alloy extruded bars, rods, wire, profiles, and tubes

- EN 755-2: European standard for extruded aluminum and aluminum alloy products

- GB/T 6892: Chinese national standard for extruded aluminum and aluminum alloy profiles

- ISO 209: International standard for chemical composition of aluminum alloys

Performance Standards

- ASTM D5470: Standard test method for thermal transmission properties of thermally conductive electrical insulation materials

- IPC-9592: Standard for design and qualification of baseplate-free power semiconductor devices

- MIL-STD-883: Military standard for microcircuits (thermal testing)

- UL 94: Standard for safety of plastic materials for parts in devices and appliances

Quality Certifications:

Manufacturing Certifications:

- ISO 9001:2015 – Quality Management System

- ISO 14001:2015 – Environmental Management System

- IATF 16949:2016 – Automotive Quality Management

- RoHS Compliance – Restriction of Hazardous Substances

Product Certifications:

- CE Marking – Conformité Européenne

- UL Certification – Underwriters Laboratories

- REACH Compliance – Registration, Evaluation, Authorization and Restriction of Chemicals

- FDA Compliance – Food and Drug Administration (for medical applications)

Real-World Applications (Stuff I’ve Actually Built)

LED Lighting (My Biggest Project)

Project Details:

- Product: 200W LED High Bay Lights

- Material: 6063-T5 Aluminum

- Size: 400mm × 200mm × 50mm

- Heat Dissipation: 180W @ 85°C junction temperature

- Production Volume: 10,000 units

Results:

These lights have been running for 3 years now with ZERO failures! The heat sinks keep the LEDs at 75°C max, which means they’ll last over 50,000 hours. The client saved $200k in energy costs in the first year alone!

Power Electronics (The Tricky One)

Project Details:

- Product: 500W Inverter Heat Sinks

- Material: 6061-T6 Aluminum

- Size: 300mm × 150mm × 80mm

- Heat Dissipation: 450W @ 100°C

- Production Volume: 5,000 units

Challenge & Solution:

The inverters had 6 power modules that needed cooling. We designed a custom heat sink with individual cooling zones. The result? 25% lower operating temperature and 3x longer component life!

Other Applications I’ve Worked On:

Automotive

- Electric motor controllers

- Battery management systems

- LED headlight cooling

- Power steering modules

Industrial

- VFD drives

- Servo motor amplifiers

- PLC systems

- Solar inverters

Consumer Electronics

- Gaming PC coolers

- Home theater amplifiers

- Projector cooling systems

- Audio amplifiers

Design Tips & Best Practices (Lessons I’ve Learned the Hard Way)

Design for Manufacturability (DFM)

- Avoid sharp corners: Use 0.5mm minimum radius – prevents stress concentration

- Standardize hole sizes: Use common drill sizes (3mm, 4mm, 5mm) to reduce tooling costs

- Consider fin aspect ratio: Keep H/D ≤ 4:1 for optimal airflow

- Include mounting features: Integrate mounting holes directly into the design

- Allow for tolerances: ±0.1mm for critical dimensions, ±0.2mm for non-critical

Thermal Design Best Practices

- Maximize surface area: More fins = better cooling (up to a point)

- Optimize fin spacing: Too close = no airflow, too far = wasted space

- Use thermal interface material: TIM can reduce thermal resistance by 50%

- Consider airflow direction: Design fins to match natural airflow patterns

- Test early: Prototype and test before finalizing design

Common Mistakes to Avoid (I’ve Made All Of These!)

Design Mistakes:

- Over-engineering – bigger isn’t always better!

- Ignoring manufacturing limitations

- Forgetting about mounting and assembly

- Not considering environmental factors

Material Mistakes:

- Choosing the wrong alloy for the application

- Not considering surface treatment needs

- Overlooking corrosion resistance requirements

- Sacrificing performance for cost savings

Frequently Asked Questions (What People Actually Ask)

Q: How do I choose between 6061 and 6063 aluminum?

A: Bro, it’s simple! If you need maximum strength and thermal conductivity, go with 6061-T6. If you’re on a budget and need great extrudability and surface finish, 6063-T5 is your guy. I usually recommend 6061 for high-power applications and 6063 for consumer electronics.

Q: What’s the minimum fin thickness you can CNC machine?

A: We can go as low as 0.5mm, but I don’t recommend it unless you have to. Thinner fins are more fragile and can vibrate or bend. I usually suggest 1.0-1.5mm for most applications – great balance of performance and durability.

Q: How much does a custom CNC heat sink cost?

A: It depends on size, complexity, and quantity. A small simple heat sink might cost $5-10 each in 1000-piece quantities. A large complex one could be $50-100 each. Tooling costs are $500-2000 for custom designs. Always get a quote before committing!

Q: Can you anodize the heat sinks?

A: Absolutely! Anodizing not only looks great but also improves corrosion resistance and can increase emissivity (which helps with radiation cooling). We offer clear, black, silver, and custom colors. Black anodized heat sinks can have 10-15% better thermal performance!

Q: How do I calculate the required heat sink size?

A: Use this formula: Thermal Resistance (°C/W) = (Max Component Temp – Ambient Temp) / Power Dissipation. Then choose a heat sink with thermal resistance LESS than that value. Or just send me your specs and I’ll calculate it for you – I do this stuff every day!

Ready to Get Started?

Whether you need a simple heat sink or a complex custom design, I’m here to help!

I’ve designed over 500 different heat sinks for all kinds of applications.

Send me your requirements:

• Power dissipation (watts)

• Maximum allowable temperature

• Space constraints (size limits)

• Mounting requirements

• Quantity needed

I’ll get back to you with a design proposal and quote within 24 hours!