No. For parts processed by different methods, forged parts generally have higher strength. Parts are repeatedly pressed during forging, which makes the fibers continuous. Also, forging can refine metal grains, so the strength of forged parts is greater than that of non – forged parts.

Introduction to Forging Processing

Forging has a long history in China and was passed down through the production mode of handicraft workshops. Around the beginning of the 20th century, it gradually emerged in industries such as railways, ordnance, and shipbuilding in the form of mechanical industrial production. The main sign of this transformation was the use of powerful forging machines.

In the automotive manufacturing process, forging processing methods are widely used. With the progress of science and technology and the continuous increase in requirements for workpiece precision, precision forging technology, which has the advantages of high efficiency, low cost, low energy consumption, and high quality, has been more and more widely applied. According to the different deformation temperatures during metal plastic forming, precision cold forging can be divided into cold forging, warm forging, sub – hot forging, and hot precision forging. The automotive parts produced include automotive clutch engaging gear rings, input shaft parts of automotive transmissions, bearing rings, automotive constant – velocity universal joint slip sleeves and their series products, automotive differential gears, automotive front axles, etc.

Classification of Forging

- Classification by production tools

- Free forging: It refers to a processing method in which simple general – purpose tools are used, or external forces are directly applied to the billet between the upper and lower anvils of the forging equipment, causing the billet to deform to obtain the required geometric shape and internal quality of the forging.

- Die forging: It means that the metal billet is deformed under pressure in a forging die cavity with a certain shape to obtain a forging. Die forging can be divided into hot die forging, warm forging, and cold forging. Warm forging and cold forging are the future development directions of die forging and also represent the level of forging technology.

- Ring rolling: It refers to the production of ring – shaped parts with different diameters through a special ring – rolling machine, and it is also used to produce wheel – shaped parts such as automotive wheels and train wheels.

- Special forging: It includes forging methods such as roll forging, cross – wedge rolling, radial forging, and liquid die forging. These methods are more suitable for producing parts with special shapes. For example, roll forging can be used as an effective pre – forming process to significantly reduce the subsequent forming pressure; cross – wedge rolling can produce parts such as steel balls and drive shafts; radial forging can produce large forgings such as gun barrels and stepped shafts.

- Classification by forging temperature

- The starting recrystallization temperature of steel is about 727°C, but 800°C is generally used as the dividing line. Forging above 800°C is hot forging; forging between 300 – 800°C is called warm forging or semi – hot forging, and forging carried out at room temperature is called cold forging. Forgings used in most industries are hot forging, while warm forging and cold forging are mainly used for the forging of parts in the automotive and general machinery industries. Warm forging and cold forging can effectively save materials.

- Classification by the movement mode of the forging die

Forging can also be divided into swing forging, swing – rotary forging, roll forging, cross – wedge rolling, ring rolling, and skew rolling according to the movement mode of the forging die.

Precision of CNC – machined Parts and Forged Parts

Although the strength, toughness, and other advantages of forged parts cannot be ignored, for products with high – precision requirements, the production method of machined parts is more suitable. Machined parts can produce products with high shape, precision, and surface roughness, and their processing capabilities are becoming higher and higher, which can meet the needs of higher – precision manufacturing.

Differences between CNC – machined Parts and Forged Parts

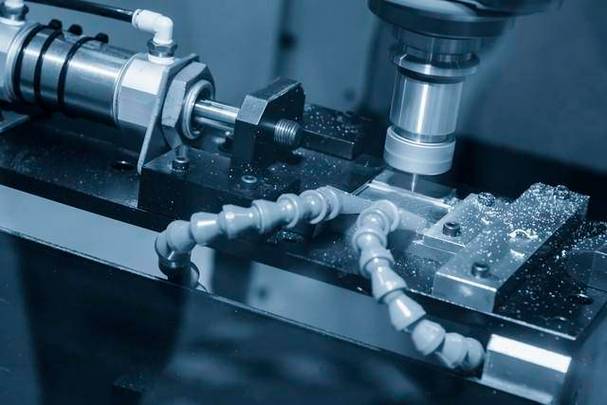

Machined parts are processed by advanced equipment such as CNC machines. They have high – precision requirements and high – complexity processes. Their performance, dimensions are stable, and the surface finish is high. Forged parts are formed by heating metal materials and processing them through forging or extrusion. Their surface dimensions and shapes are not as stable as those of machined parts, but they have high strength, good toughness, and strong fatigue resistance.

CNC machining and forging are two different metal processing technologies, each with its own characteristics and application scenarios.

CNC machining (Computer Numerical Control machining) is a precision processing technology under computer – digital control, suitable for the production of small – batch customized parts. It can process various complex geometric shapes, providing high precision and surface quality. However, the cost increases as the production volume increases, and more waste is generated. CNC machining can achieve special processes and complex surface treatments, such as chamfering, pattern engraving, and drilling at bends, which is suitable for personalized requirements and customized parts.

Forging is a process of applying external forces to make metal materials plastically deformed to form the required shape. It can eliminate internal looseness and pores in the metal and optimize the microstructure, thereby improving the strength and toughness of the material. Forging is divided into free forging, die forging, and other forms, and is suitable for the mass production of high – strength and high – toughness parts. The forged materials usually need further heat treatment to achieve the best performance.

When manufacturing tools, if the ultimate performance is pursued, the tools directly cut by CNC are likely to have stronger performance than those repeatedly forged. However, this also depends on the initial state of the steel billet and the degree of forging. Modern high – strength steel can achieve high performance through direct CNC processing, and excessive forging may instead affect the performance. Nevertheless, forging still has value in certain specific scenarios, such as the homogenization of high – strength steel and the strengthening of certain specific structures.

When choosing between CNC machining and forging, factors such as production volume, cost, precision, surface quality, and application scenarios need to be considered. CNC machining is suitable for small – batch and high – precision needs, while forging is suitable for large – batch parts that require high strength. In some cases, combining the two processes can better meet product requirements.