Whether you’re prototyping a new bracket, producing small-batch components, or scaling up to mass manufacturing, the right metal stamping kit can make or break your project’s success. A high-quality stamping kit combines precision tools, durable dies, and compatible accessories to transform raw metal sheets into consistent, accurate parts—critical for industries from automotive to electronics. At Goldcattle, with over 26 years of expertise in metal fabrication, we understand what makes a stamping kit truly effective: reliability, versatility, and performance that scales with your needs. Let’s explore the components of the best metal stamping kits, how to choose the right one, and why Goldcattle’s custom solutions stand out.

Core Components of a Top-Tier Metal Stamping Kit

A complete metal stamping kit isn’t just a press and a die—it’s a system designed to work in harmony, ensuring safety, efficiency, and precision. Here are the essential elements:

1. Precision Stamping Press: The Powerhouse

The press is the heart of any stamping kit, providing the force to shape metal. The best kits include presses rated for your material thickness and part size:

- Manual presses: Ideal for small parts (≤30mm) and low-volume projects, offering 1–5 tons of force for thin metals like aluminum (0.3–1mm thick) .

- Semi-automatic presses: Perfect for medium batches, with 5–50 tons of force, capable of stamping steel sheets up to 3mm thick at 10–30 parts per minute .

- Hydraulic presses: For heavy-duty applications, delivering 50–500 tons of force for thick metals (3–10mm) like carbon steel or stainless steel.

Goldcattle’s recommended semi-automatic press (20 tons) recently helped a client produce 5,000 aluminum brackets with consistent 0.02mm tolerance, reducing rework by 35% compared to their old manual press.

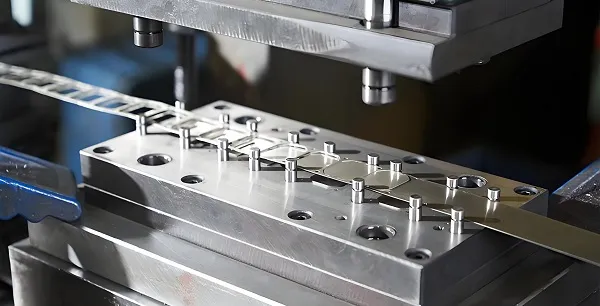

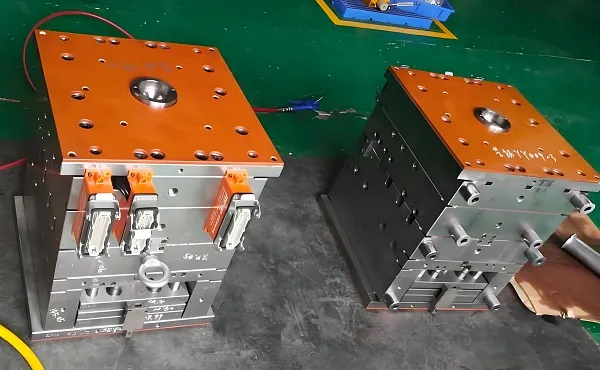

2. Custom Dies: The Blueprint for Accuracy

No stamping kit is complete without high-quality dies, which determine the final shape of your parts. The best dies are:

- Material-matched: Made from tool steel (e.g., Cr12MoV or H13) for durability, with hardness up to 58–62 HRC to resist wear .

- Precision-machined: CNC-machined to ±0.005mm accuracy, ensuring parts meet tight tolerances for holes, bends, and contours.

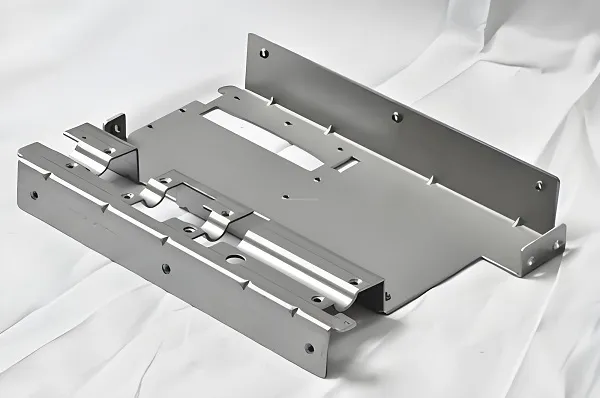

- Application-specific: Designed for your part’s geometry—whether it’s a simple blanking die for washers or a progressive die for complex brackets with multiple features.

For a electronics client’s terminal connectors, Goldcattle’s custom progressive die integrated cutting, bending, and piercing in one cycle, increasing production speed by 40% compared to using separate dies.

3. Material Handling & Safety Accessories

A professional stamping kit includes tools to protect operators and streamline workflow:

- Feeding systems: Automatic sheet feeders or coil handlers for consistent material placement, reducing human error.

- Safety guards: Light curtains and emergency stops to prevent accidents during high-speed operation.

- Lubrication systems: Spray or roller applicators to reduce friction between die and metal, extending die life by up to 50% .

Goldcattle’s safety-certified kits include CE-compliant guards and automatic lubrication, ensuring compliance with OSHA standards for a client’s automotive parts facility.

Key Factors to Choose the Best Metal Stamping Kit

Not all stamping kits are created equal. To find the best one for your needs, focus on these critical factors:

1. Material Compatibility

The kit must handle your metal type and thickness. For example:

- Aluminum (6061): Requires lower force (5–20 tons) and dies with polished surfaces to prevent galling.

- Stainless steel (304): Needs higher force (20–50 tons) and heat-treated dies to resist wear from its high strength (≥500 MPa tensile strength) .

- Brass/copper: Works with medium-force presses but requires lubrication to maintain surface finish.

Goldcattle’s technical team analyzes your material specs to recommend kits that balance force and precision—recently advising a brass component manufacturer to upgrade to a 30-ton press, eliminating part deformation.

2. Production Volume & Speed

Match the kit to your output needs:

- Prototyping/small batches (1–100 parts): A manual press with a single die offers cost-effective flexibility.

- Medium batches (100–10,000 parts): Semi-automatic presses with quick-change dies reduce setup time.

- Large batches (10,000+ parts): Automatic presses with progressive dies maximize throughput (up to 100 parts per minute) .

A furniture manufacturer using Goldcattle’s medium-batch kit increased monthly output of steel brackets from 2,000 to 8,000 parts without adding labor.

3. Tolerance Requirements

For precision parts (e.g., aerospace components or medical devices), choose a kit with:

- Presses with minimal deflection (≤0.01mm per ton of force).

- Dies machined on 5-axis CNC centers for tight feature alignment.

- Inline inspection tools (e.g., optical comparators) to verify dimensions.

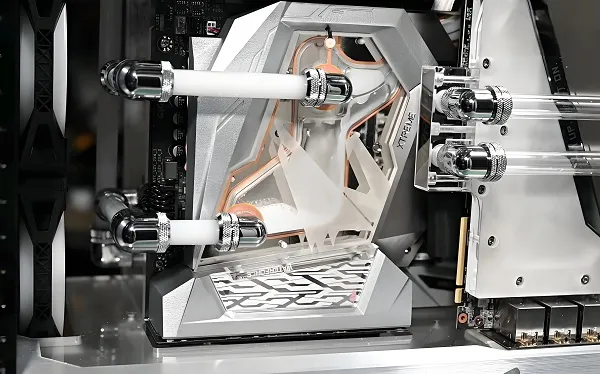

Goldcattle’s high-precision kit helped a medical device client achieve ±0.01mm tolerance on stainless steel surgical tool components, meeting ISO 13485 standards.

Why Goldcattle Delivers the Best Custom Metal Stamping Kits

- Tailored Solutions: We don’t offer “one-size-fits-all” kits. Instead, we design systems around your parts, materials, and production goals—recently building a custom kit for a robotics client that integrated stamping, deburring, and quality checks in one cell.

- Durable Components: Our dies use premium tool steel and undergo heat treatment for 500,000+ cycles, while presses feature reinforced frames to maintain precision over time.

- Technical Support: From kit selection to training, our engineers provide guidance on setup, maintenance, and process optimization—reducing downtime for new users by 60%.

- Compliance: Kits meet global standards (ISO 9001, CE, OSHA) for safety and quality, critical for regulated industries like automotive and healthcare.

FAQs About Choosing the Best Metal Stamping Kit

Q: What’s the minimum investment for a quality metal stamping kit?

A: Entry-level manual kits start at (5,000–)10,000, while semi-automatic systems for medium batches range from (20,000–)50,000. Custom large-scale kits vary based on complexity.

Q: Can a single kit handle multiple part designs?

A: Yes! Quick-change die systems allow switching between parts in 15–30 minutes, making the kit versatile for product lines with multiple SKUs.

Q: How long does a stamping die last in a quality kit?

A: With proper maintenance, tool steel dies last 500,000–1,000,000 cycles for steel parts and 1–2 million cycles for aluminum or brass .

Q: What safety features are non-negotiable in a stamping kit?

A: Essential features include light curtains, emergency stop buttons, two-hand operation controls, and die guards to prevent operator contact with moving parts.

Q: Can Goldcattle help train my team to use the kit?

A: Absolutely. We provide on-site training covering press operation, die setup, maintenance, and safety protocols to ensure efficient, accident-free production.

Ready to Build Your Perfect Metal Stamping Kit?

The best metal stamping kit isn’t just about tools—it’s about finding a solution that aligns with your materials, volume, and precision needs. At Goldcattle, we combine expertise, quality components, and customization to create kits that deliver consistent results, reduce costs, and scale with your business.

Visit https://www.xmgoldcattle.com/ to discuss your project requirements or request a free kit consultation. Let’s build a stamping system that powers your production success.

Got a specific part or material in mind? Share your needs below—our stamping experts will recommend the ideal kit for you!