- Programmed positioning: X/Y/Z axes move the drill to exact coordinates (e.g., ±0.005mm accuracy).

- Controlled spindle speed/feed: Optimizes cutting parameters for different materials (e.g., aluminum vs. steel).

- Automated cycles: Peck drilling (for deep holes) or countersinking (for screw heads) reduces human error.

2. Why CNC Drilling Outperforms Traditional Manual Drilling

|

Advantage

|

CNC Drilling Performance

|

Traditional Manual Drilling Performance

|

Industry Data Support

|

|

Position Accuracy

|

±0.005-0.01mm (via servo-driven axes)

|

±0.1-0.3mm (reliable on operator skill)

|

Reduces hole position error by 95% (Source: CNC Precision Study 2025)

|

|

Dimensional Consistency

|

Batch hole size deviation ≤0.003mm

|

Batch deviation ≥0.05mm (due to hand tremors)

|

99.8% first-pass qualification rate for CNC (vs. 85% manual)

|

|

Efficiency

|

3-5x faster (200 holes/hour for φ5mm steel holes)

|

40-60 holes/hour (operator fatigue slows speed)

|

Cuts drilling time by 60% for automotive parts (Source: Manufacturing Efficiency Report)

|

|

Complex Hole Machining

|

Drills blind holes, stepped holes, angled holes

|

Limited to simple through holes (angle/ depth hard to control)

|

70% of aerospace complex holes rely on CNC (Source: Aerospace Machining Guide)

|

|

Automation

|

24/7 unattended operation (with auto-loaders)

|

Requires constant operator supervision

|

Reduces labor cost by 40% for high-volume production

|

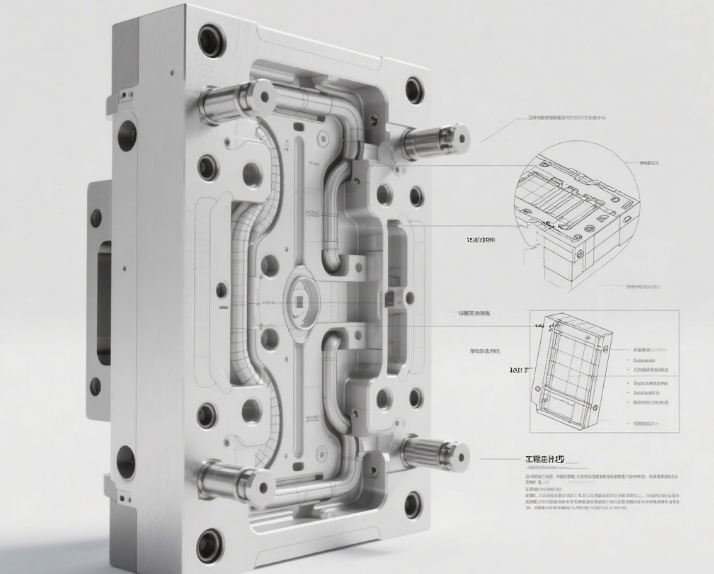

3. Key Types of CNC Machines for Drilling

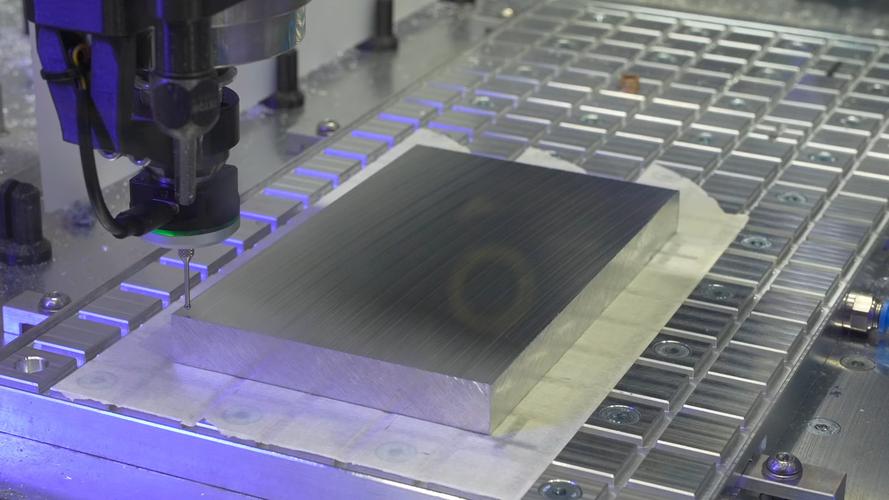

A. CNC Milling Centers (3/4/5-Axis)

- Core Strength: Drills holes in irregular parts (e.g., brackets, housings) via X/Y/Z-axis positioning; 5-axis models handle angled holes (e.g., 45° holes in engine blocks).

- Typical Application: Drilling 6×φ8mm through holes in an aluminum bracket (positioned at (10,20), (30,20), etc.).

- Key Feature: Supports “drill-tap-mill” integration (drills holes, taps threads, and mills chamfers in one setup).

B. CNC Turning Centers (With C-Axis)

- Core Strength: Drills radial/axial holes in rotational parts (e.g., shafts, bushings); C-axis indexes the workpiece to drill holes at specific angles (e.g., 90° cross holes in a shaft).

- Typical Application: Drilling a φ6mm axial hole (along Z-axis) and a φ4mm radial hole (perpendicular to Z-axis) in a φ30×100mm steel shaft.

- Key Feature: Uses “live tooling” (rotating tools on the turret) to drill while the workpiece is clamped.

C. Dedicated CNC Drill Centers (PCB/Metal)

- Core Strength: High-speed drilling for small, dense holes (e.g., PCB circuit boards, thin metal sheets); some models drill up to 10,000 holes/hour.

- Typical Application: Drilling 0.1mm micro-holes in a PCB (used in smartphones).

- Key Feature: Specialized spindles (10,000-60,000r/min) for micro-drilling.

4. Critical CNC Drilling Technologies (Precision & Safety)

A. Tool Selection: Match Drill to Material & Hole Type

|

Drill Type

|

Material Compatibility

|

Hole Type Application

|

Key Parameters

|

|

Twist Drill

|

Steel, aluminum, copper (general-purpose)

|

Through holes, blind holes (depth ≤5×diameter)

|

High-speed steel (HSS): Vc=20-50m/min; Carbide: Vc=80-150m/min

|

|

Spot Drill

|

All materials (pre-drilling guide)

|

Guides twist drills (prevents wandering)

|

Tip angle 90° (matches twist drill tip angle)

|

|

Deep-Hole Drill

|

Steel, stainless steel (depth >5×diameter)

|

Deep blind holes (e.g., 20×φ5mm holes)

|

Uses internal coolant holes (for chip evacuation)

|

|

Counterbore Drill

|

Steel, aluminum (for bolt heads)

|

Stepped holes (e.g., φ8mm hole + φ12mm counterbore)

|

Counterbore depth = bolt head height (e.g., 3mm for M8 bolts)

|

B. Peck Drilling: Solve Deep Hole Chip Evacuation

- Problem: Deep holes (depth >5×diameter) trap chips, causing drill breakage or hole scuffing.

- Solution: Peck drilling (G83 code for FANUC) — drills in small “pecks” (e.g., 2×diameter per peck) and retracts to evacuate chips.

- Program Example (φ5mm hole, depth 30mm):

- G83 X10 Y20 Z-30 R2 Q10 F100 // Q10=peck depth 10mm, R2=safe distance above workpiece

C. Spindle Speed & Feed Rate Optimization

- Rule of Thumb: Harder materials = lower speed + lower feed; softer materials = higher speed + higher feed.

|

Material

|

Drill Material

|

Spindle Speed (S)

|

Feed Rate (F)

|

|

45# Steel (HB200)

|

Carbide Twist Drill

|

1200r/min

|

50mm/min (φ5mm)

|

|

6061 Aluminum

|

Carbide Twist Drill

|

3000r/min

|

150mm/min (φ5mm)

|

|

304 Stainless Steel

|

Carbide Twist Drill

|

800r/min

|

30mm/min (φ5mm)

|

D. Coolant Application: Reduce Heat & Wear

- Through-Hole Drilling: External coolant (flow rate ≥15L/min) — cools the drill tip and flushes chips.

- Deep-Hole Drilling: Internal coolant (pressure ≥5MPa) — delivers coolant directly to the cutting zone (reduces drill wear by 30%).

5. Practical Case: CNC Milling Center Drilling φ8mm Holes in a Steel Bracket

Step 1: Equipment & Tool Preparation

- Machine: FANUC 0i-MF 3-axis milling center.

- Tools: φ6mm spot drill (for guiding), φ8mm carbide twist drill (for final drilling), coolant system (20L/min flow).

Step 2: Process Planning

- Spot Drilling: Create 2mm-deep guide holes (prevents drill wandering).

- Final Drilling: Drill φ8mm through holes (depth 10mm) via peck drilling (G83).

- Deburring: Use a φ10mm countersink (G82) to remove burrs (chamfer 0.5×45°).

Step 3: Programming Snippet (FANUC System)

Step 4: Quality Verification

- Position Check: Use a coordinate measuring machine (CMM) to confirm hole positions (deviation ≤0.008mm).

- Size Check: Use a pin gauge (φ8H7) — gauge should pass through without resistance.

- Surface Check: Inspect hole walls with a borescope (Ra=2.8μm, meets requirement).

6. Common CNC Drilling Problems & Solutions

1. Hole Deviation (Drill Wanders)

- Cause: No spot drilling (drill tip slips on workpiece surface) or spindle runout (>0.002mm).

- Solution:

-

- Add spot drilling (depth = 1-2×drill diameter) before final drilling.

-

- Calibrate spindle runout (replace bearings if >0.002mm).

2. Drill Breakage (Deep Holes)

- Cause: Chips trapped in hole (no peck drilling) or feed rate too high.

- Solution:

-

- Use peck drilling (G83) with Q=2-3×drill diameter (for deep holes).

-

- Reduce feed rate by 20% (e.g., from 50mm/min to 40mm/min for stainless steel).

3. Oversized Holes (Diameter > Requirement)

- Cause: Drill wear (flutes dull) or tool offset set incorrectly.

- Solution:

-

- Replace dull drills (check for worn flutes with a magnifier).

-

- Adjust tool offset (e.g., if hole is φ8.005mm, reduce X-axis offset by 0.0025mm).

7. Q&A: High-Frequency CNC Drilling Questions

Q1: Can CNC drill micro-holes (diameter <0.5mm)?

- Yes—use dedicated micro-drills (tungsten carbide with diamond coating) and high-speed spindles (30,000-60,000r/min). For example, CNC PCB drill centers drill 0.1mm holes in circuit boards with ±0.001mm accuracy.

Q2: How to drill angled holes (e.g., 30° from workpiece surface)?

- Use a 5-axis CNC milling center (tilts the workpiece or drill to 30°) or a 3-axis machine with an angle plate (clamps the workpiece at 30°). Program the hole coordinates in the tilted coordinate system (G54/G55).

Q3: What’s the maximum depth of a CNC-drilled hole?

- For standard twist drills: Up to 5×diameter (e.g., φ5mm drill → 25mm depth). For deep-hole drills (with internal coolant): Up to 30×diameter (e.g., φ10mm deep-hole drill → 300mm depth). Beyond that, use gun drilling (a specialized deep-hole process).