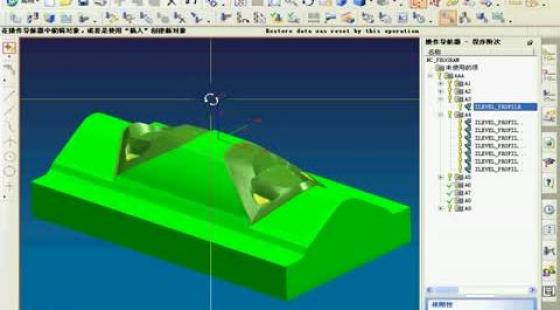

What are CNC Milling Contour Lines?

CNC milling contour lines, also known as Z-level machining or contour parallel toolpaths, are horizontal cutting paths generated at specific Z-heights that follow the surface geometry of a workpiece. This…

CNC milling contour lines, also known as Z-level machining or contour parallel toolpaths, are horizontal cutting paths generated at specific Z-heights that follow the surface geometry of a workpiece. This…

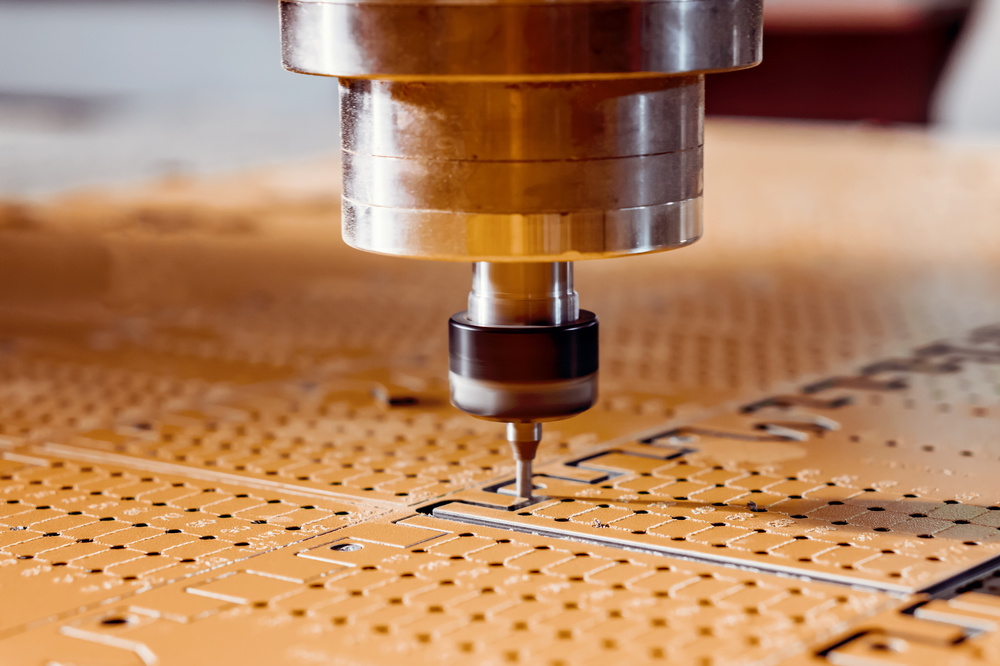

The answer is: For CNC contour milling, the most commonly used tools are end mills, with square end mills for sharp corners and ball nose end mills for complex 3D…

Cast metal refers to metal alloys formed by pouring molten material into a mold and allowing it to solidify into a specific shape. This manufacturing process has been used for…

The answer is: No, vertical movement on CNC mills doesn’t have to use G01! The choice between G00, G01, or other G-codes depends on the purpose of the movement and…

The answer is: The 4t rule is an important safety guideline for sheet metal bending! It tells us that the minimum inside bend radius should be four times the material…

Yes, it can! An end mill can not only make a cube, but it can make it very precisely! Today I want to show you an amazing “metal transformation magic…

Sticking in injection molded parts occurs when the plastic part adheres to the mold surface during ejection, primarily caused by insufficient draft angles, poor surface finish, inadequate cooling, improper process…

Cracking in injection molded parts is primarily caused by internal stresses exceeding material strength limits, typically resulting from uneven cooling, improper process parameters, design flaws, material issues, or environmental factors…

Bubbles in injection molded parts are cavities formed by trapped gases, moisture vaporization, or vacuum voids due to uneven cooling and shrinkage, typically caused by material moisture, poor venting, process…

Metal Injection Molding (MIM) combines plastic injection molding with powder metallurgy to produce complex metal parts by mixing fine metal powders with binders, injecting into molds, removing binders, and sintering…