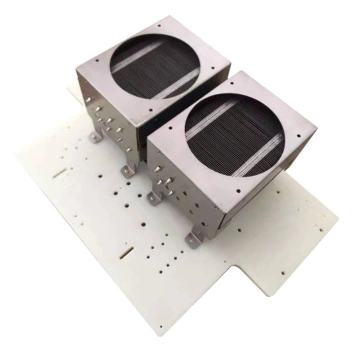

Aluminum Alloy CNC Machining

In the dynamic landscape of modern manufacturing, aluminum alloy CNC machining has emerged as a cornerstone technology for producing high-performance

首页 » Industry Encyclopedia » Page 30

In the dynamic landscape of modern manufacturing, aluminum alloy CNC machining has emerged as a cornerstone technology for producing high-performance

Bro, Let’s Talk About REAL Thermal Management! Alright listen up, if you’re dealing with electronics that run HOT, you NEED

In the dynamic landscape of modern manufacturing, precision machining is the cornerstone of innovation across industries. Our CNC machining services

In the high – stakes world of automotive manufacturing, precision is not just a requirement—it’s the foundation of safety, performance,

In the ever – evolving landscape of modern manufacturing, CNC machining of plastic parts made from materials like POM (Polyoxymethylene),

In the rapidly advancing field of modern manufacturing, aluminum machining using CNC technology has become a pivotal force in producing

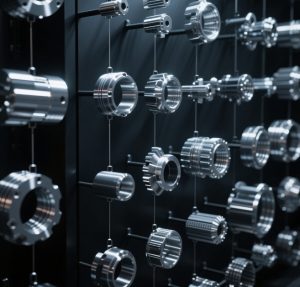

In the ever – evolving landscape of modern manufacturing, CNC machining turning parts have emerged as a cornerstone for producing

In the highly competitive and technologically advanced automotive industry, the pursuit of enhanced performance, reliability, and safety drives the demand

In the dynamic realm of modern manufacturing, the demand for parts that precisely meet unique requirements has given rise to

In the ever – evolving manufacturing landscape, high – demand stainless steel CNC machining parts have emerged as essential components