cnc machining automotive parts

In the highly competitive and technologically advanced automotive industry, the demand for precision – made components is non – negotiable.

首页 » Industry Encyclopedia » Page 31

In the highly competitive and technologically advanced automotive industry, the demand for precision – made components is non – negotiable.

Titanium alloy, a star material known as the “space metal”, has become the core choice for aerospace, medical implants, and

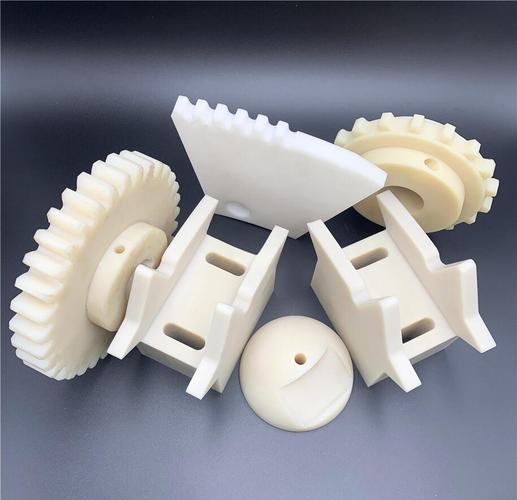

Author: Sun Gong,MC Nylon Specialist, 15+ Years Experience | Last Updated: January 19, 2026 In the field of high-end engineering

In an era of pursuing precision and customization, CNC (Computer Numerical Control) technology has long broken through the boundaries of

In the dynamic landscape of modern manufacturing, the demand for high – precision brass components has never been greater. Combining

In the dynamic landscape of modern manufacturing, CNC custom machining of milling and turning parts stands as a cornerstone of

Anodized aluminum CNC machining service, through high – precision processing technology, integrated surface treatment design, and an intelligent production system,

Stainless Steel CNC Turning Parts – Precision Machining Services | Xiamen Goldcattle (26 Years Expertise) In aerospace, medical devices, and

In fields such as food machinery, medical devices, and aerospace, where extremely high requirements for corrosion resistance and strength are

What Is Precision CNC Machining? Let’s Break It Down CNC Machining 101 – The Basics Bro, CNC stands for Computer