Hey everyone—let’s start with a quick show of hands: How many of you have stared at a piece of ceramic, thought “I need to machine this,” and then paused… because you’ve heard horror stories? Maybe a colleague told you their ceramic part shattered mid-cut. Or you tried using your go-to metal CNC setup, only to ruin a $500 ceramic blank.

If that’s you—you’re not alone. Ceramic CNC machining isn’t like cutting aluminum or plastic. This material is tough (we’re talking harder than steel) but brittle (think: one wrong move, and it cracks). But here’s the thing: It’s also one of the most valuable materials in manufacturing today—used in everything from aerospace turbine blades to medical implants to high-tech electronics.

So today, we’re going to demystify ceramic CNC machining. No jargon overload, no vague advice—just practical, human-focused insights on why it’s hard, how to do it right, and where it matters most. Let’s dive in.

First: Why Is Ceramic CNC Machining So Tricky? (Let’s Talk About Ceramic’s “Personality”)

Before we get to solutions, we need to understand the problem: Ceramic’s unique properties make it a “high-maintenance” material for machining. Let’s break it down like we’re talking about a coworker’s quirks—relatable, not just technical:

- It’s extremely hard—too hard for regular tools:

Take alumina ceramic, the most common type—its hardness hits HRA 88-92. For context, 淬火钢 (quenched steel) is around HRA 60-65. That means your standard carbide endmill? It’ll wear out in 5 minutes flat. Imagine trying to cut a steak with a butter knife—same energy.

- It’s brittle—no room for “oops”:

Ceramic’s fracture toughness is just 1.5-4 MPa・m¹/². Compare that to aluminum (20 MPa・m¹/²) or even glass (5 MPa・m¹/²)—ceramic is more likely to shatter if you apply too much force, or if the tool vibrates even a little. I once saw a machinist push the feed rate 10% too high—entire ceramic insulator cracked into 3 pieces. Waste of 2 hours and $300.

- It’s abrasive—grinds down tools fast:

Ceramic particles are like tiny sandpaper. Even if you use a diamond tool (the only thing hard enough), the ceramic will wear down the tool’s edge over time. A diamond endmill that lasts 100 hours on aluminum? Maybe 10-15 hours on ceramic.

- Heat is its enemy:

Unlike metal, ceramic doesn’t conduct heat well. When you cut it, heat builds up at the tool-workpiece interface—no place for it to go. That heat can cause “thermal shock”: the ceramic expands slightly, then cracks when it cools. I’ve had parts look perfect mid-cut, only to split 10 minutes later because of unmanaged heat.

The Good News: 5 Key Techniques to Make Ceramic CNC Machining Work (Pro Tips Inside)

Now, let’s shift from “why it’s hard” to “how to do it right.” These aren’t just textbook ideas—they’re tricks I’ve seen veteran machinists use to turn out perfect ceramic parts, every time.

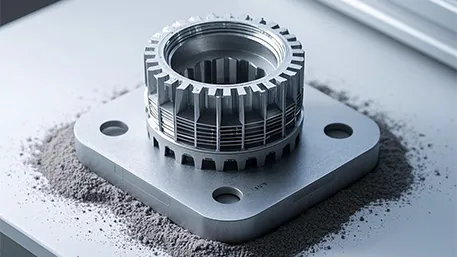

1. Start with the right tool—diamond is non-negotiable

Forget carbide. Forget HSS. For ceramic CNC machining, you need diamond tools—either polycrystalline diamond (PCD) or single-crystal diamond (SCD). Here’s the breakdown:

- PCD tools: Great for “roughing cuts” (removing most material). They’re more affordable than SCD and hold up to abrasive ceramic. Use a PCD endmill with a “negative rake angle” (10-15°)—this reduces cutting force, so you don’t shock the ceramic.

- SCD tools: For “finishing cuts” (getting that smooth surface). They can hit surface roughness as low as Ra 0.02 μm—critical for medical parts (like zirconia 牙冠,dental crowns) or optical components.

Pro tip: Never use a worn diamond tool. A dull edge will “push” the ceramic instead of cutting it—guaranteed 崩边 (chipping). Check the tool edge with a microscope every 2-3 hours.

2. Slow down—speed kills with ceramic

I know, we all want to be efficient. But with ceramic, “fast” = “failed.” Here’s the sweet spot for parameters (based on alumina ceramic, adjust for other types like zirconia or silicon carbide):

- Spindle speed: 8,000-12,000 RPM (slower than aluminum’s 15,000-20,000 RPM). Too fast causes vibration; too slow leads to more heat.

- Feed rate: 50-150 mm/min (vs. 300-500 mm/min for aluminum). A slow feed rate lets the tool cut cleanly, not smash through the ceramic.

- Depth of cut: Max 0.1-0.2 mm per pass. Think of it like peeling an apple—thin layers, not big chunks. Deep cuts put too much stress on the ceramic.

Story time: A client once asked me to “speed up” their ceramic sensor machining. I warned them, but they insisted. We upped feed rate to 200 mm/min—first 3 parts cracked. We dialed it back to 120 mm/min, and suddenly, 50 parts in a row were perfect. Slow wins.

3. Cool it—the right way

Heat is ceramic’s kryptonite, so you need a cooling system that’s more than just a squirt of water. Here’s what works:

- Oil mist cooling: The best option for ceramic. It sprays a fine mist of cutting oil (use a high-viscosity oil, like ISO 46) directly at the tool-workpiece interface. The mist cools the area and lubricates the tool—reducing wear by 30%.

- Avoid flood cooling: Pouring water over ceramic can cause thermal shock (cold water hits hot ceramic, cracks it). Save flood cooling for metal.

Pro tip: Position the mist nozzle as close to the cut as possible—1-2 mm away. If it’s too far, the mist won’t reach the heat zone.

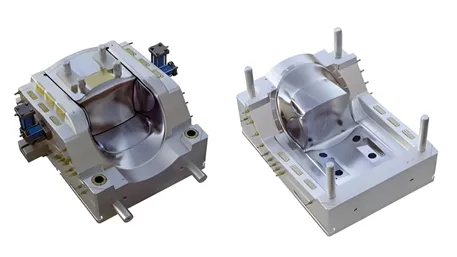

4. Secure the ceramic—no movement allowed

Even 0.01 mm of workpiece movement will ruin a ceramic part. So forget flimsy vises—use these setups:

- Vacuum chucks: Perfect for flat ceramic parts (like circuit boards or sensors). The vacuum holds the ceramic tightly without clamping force—no risk of cracking from pressure.

- Custom jigs with soft pads: For irregular shapes (like ceramic turbine blades). Line the jig with rubber or felt pads—they cushion the ceramic while keeping it stable.

I’ve seen this mistake: A machinist used a standard metal vise to hold a thin ceramic sheet. The vise’s jaws squeezed too hard—ceramic cracked before the cut even started. Don’t let that be you.

5. Finish smart—deburr like your part depends on it

Ceramic burrs are sharp (like tiny shards of glass) and can ruin assembly. But you can’t just file them—you’ll scratch the ceramic. Here’s how to deburr safely:

- Abrasive flow machining (AFM): For internal holes or tight spaces. A soft abrasive media (like silicone mixed with diamond dust) flows through the part, smoothing burrs without damaging the surface.

- Ultrasonic cleaning: For small burrs on external surfaces. Submerge the part in a cleaning solution and hit it with ultrasonic waves—burrs fall off in 5-10 minutes.

Why it matters: A medical device company once had to recall 1,000 ceramic implants because of unremoved burrs—they scratched patients’ tissue. Deburring isn’t a “nice-to-have”; it’s critical.

Where Does Ceramic CNC Machining Shine? (Real-World Uses You’ll Recognize)

Let’s talk about why we bother with ceramic’s “tough personality”—because it solves problems no other material can. Here are 3 industries where ceramic CNC machining is non-negotiable:

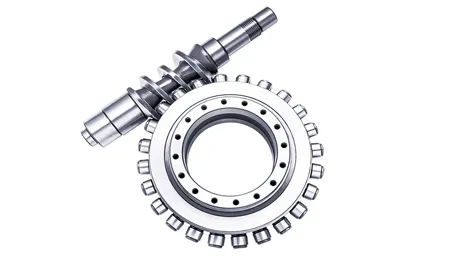

- Aerospace: Ceramic turbine blades. Jet engines get up to 1,600°C—metal melts, but ceramic stays strong. CNC machining shapes these blades into complex airfoils (curved surfaces) with ±0.01 mm tolerance—any mistake, and the engine fails.

- Medical: Zirconia dental crowns. Zirconia is biocompatible (no allergic reactions) and matches tooth color. CNC machining carves a crown from a zirconia blank in 20 minutes—perfectly fitting the patient’s tooth (thanks to SCD tools for smoothness).

- Electronics: Ceramic circuit boards. Ceramic is an excellent insulator (no electrical leakage) and dissipates heat well (critical for 5G chips). CNC machining drills tiny holes (0.1 mm diameter) for wires—something metal can’t do without shorting.

Let’s Wrap This Up: Ceramic CNC Machining Isn’t Scary—It’s Just Different

To all the machinists, engineers, and product designers here: Ceramic CNC machining doesn’t have to be a “nightmare project.” It’s just a material that asks for respect—the right tools, slow and steady parameters, and smart cooling.

Think of it like cooking a delicate dish: You wouldn’t rush a soufflé, and you shouldn’t rush ceramic. Take the time to choose a diamond tool, dial in the feed rate, and secure the part properly—and you’ll get a part that’s stronger, more heat-resistant, and more durable than any metal or plastic.

And if you’re just starting out? Don’t be afraid to test small. Grab a cheap ceramic blank (alumina is a good start), use a PCD tool, and practice roughing cuts first. Mistakes happen—but each one teaches you ceramic’s “quirks” a little better.

Ceramic isn’t just a “hard material”—it’s a material that lets you build better products. And with the right CNC machining skills? You’re the one who makes that happen.

Now—who’s ready to give ceramic CNC machining a try? If you have questions about your specific project (whether it’s a tiny sensor or a big turbine blade), drop a comment or reach out. Let’s make ceramic work for you.