CNC aluminum alloy machining, with its high precision, complex structures, and excellent surface quality, has become a core manufacturing technology in industries such as electronics, automotive, and aerospace. Choose XiaMenGoldcattle. With 26 years of professional experience and over 100 high – end devices, we offer a one – stop precision machining solution from design to production.

With the development of the times, there are more than 700,000 types of aluminum alloy products, all manufactured by CNC processing technology, which are widely used in construction, transportation, aerospace, industry, electronics, etc. Aluminum alloy parts are widely used in industrial products because of their good physical properties. Almost all welding methods can be used to weld aluminum and aluminum alloys. However, aluminum and aluminum alloys have different adaptabilities to various welding methods.

What is CNC Aluminum Alloy Machining?

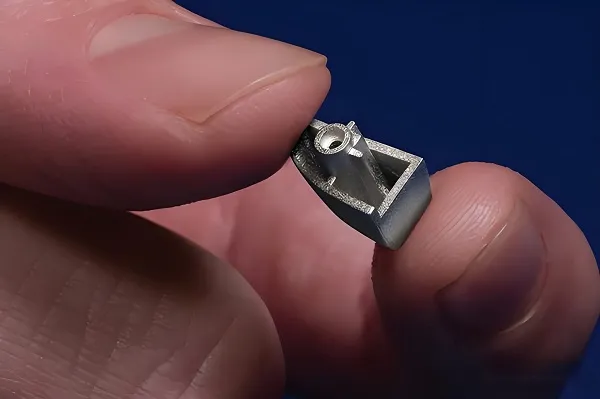

CNC aluminum alloy machining refers to a series of processing operations such as precision cutting, engraving, and drilling of aluminum alloy materials using computer numerical control (CNC) technology. This automated manufacturing method is characterized by high efficiency, high precision, good repeatability, and flexible operation, and can meet the processing requirements of various complex parts.

During the CNC aluminum alloy machining process, the design plan of the part is first completed through 3D design software, and then the design data is transmitted to the CNC equipment. The equipment precisely cuts the aluminum alloy raw materials according to the program instructions to produce parts that meet the specifications. Utilizing multi – axis processing capabilities, CNC aluminum alloy machining can also achieve the processing of complex contours, fine details, and difficult structures.

Introduction to CNC Aluminum Alloy Machining Materials

The aluminum used for CNC machining is not pure aluminum. It always contains a small amount of alloying elements. Standard aluminum still contains 99% to 99.6% aluminum (element) by weight, and the remaining percentage is composed of common materials such as silicon, manganese, magnesium, copper, and zinc.

By slightly adjusting the content of alloying elements, countless aluminum alloys can be manufactured. These common aluminum alloys are classified into 9 series according to the main alloying elements, and each series has some common properties. For example, the 3000, 4000, and 5000 series of aluminum alloys cannot be heat – treated but are cold – worked, that is, the so – called work hardening.

Main Aluminum Grades

1000 Series

Among all series, the 1000 series has the highest aluminum content, with a purity of over 99.00%. Since it does not contain other metal elements, the production process is relatively simple, and the price is relatively cheap. It is the most commonly used series in conventional industries at present. Most of the products on the market are 1050 and 1060.

2000 Series

The representative models of the 2000 series of aluminum alloys are 2024, 2A16 (LY16), and 2A02 (LY6). The 2000 series of aluminum is characterized by high hardness, with the highest copper content, approximately 3 – 5%. Manganese, magnesium, lead, and bismuth are also added for machinability. The 2000 series of aluminum belongs to aviation aluminum materials and is not commonly used in conventional industries at present.

3000 Series

The representative models of the 3000 series of aluminum alloys are mainly 3003 and 3A21. The production process of 3000 series aluminum plates in China is relatively excellent. The 3000 series aluminum rods have manganese as the main component, with a content of 1.0 – 1.5, and it is a series with good anti – rust function. 3004 aluminum also contains magnesium and is the aluminum alloy commonly used in aluminum beverage cans.

4000 Series

The representative model of the 4000 series of aluminum alloys is 4A01. The aluminum plates of the 4000 series belong to the series with a relatively high silicon content, usually with a silicon content of 4.5 – 6.0%. It is a building material, forging material for mechanical parts, and welding material, with characteristics such as low melting point and good corrosion resistance. 4043 aluminum is used as a filler rod material for welding 6000 series aluminum alloys, and 4047 aluminum is used as thin plates and claddings in construction.

5000 Series

The representative models of the 5000 series of aluminum alloys are 5052, 5005, 5083, and 5A05. The main element of the 5000 series of aluminum is magnesium, with a magnesium content of 3 – 5%, and it can also be called an aluminum – magnesium alloy. In China, the 5000 series of aluminum plates is one of the relatively mature aluminum plate series. Its main characteristics are low density, high tensile strength, high elongation, good fatigue strength, but it cannot be strengthened by heat treatment. Under the same area, the weight of the aluminum – magnesium alloy is lower than that of other series, and it is also widely used in conventional industries.

6000 Series

The representative model of the 6000 series of aluminum alloys is 6061. The 6000 series mainly contains two elements, magnesium and silicon. This series is usually easy to process and can be precipitation – hardened. For example, 6061 is a cold – treated aluminum forging product suitable for applications with high requirements for corrosion resistance and oxidation resistance.

7000 Series

The representative model of the 7000 series of aluminum alloys is 7075. The 7000 series belongs to the aviation series, mainly containing zinc elements, and also contains copper, chromium, and magnesium. It can be made the strongest among all aluminum alloys through precipitation hardening. It belongs to super – hard aluminum alloys, with good wear resistance and good weldability, but poor corrosion resistance.

8000 Series

The 8000 series is a general term for aluminum alloys that do not belong to any other category. For example, 8176 aluminum contains 0.6% iron and 0.1% silicon by weight and is used to manufacture wires.

The 8000 series of aluminum alloys is a general term for aluminum alloys that do not belong to the above – mentioned categories. These alloys can contain many other elements, such as iron and lithium. For example, 8176 aluminum contains 0.6% iron and 0.1% silicon by weight and is commonly used to manufacture wires.

9000 Series

The 9000 series of aluminum alloys is a reserve alloy.

Advantages of CNC Aluminum Alloy Machining:

①Greatly reduce the number of toolings. Complex toolings are not required for machining parts with complex shapes. If you want to change the shape and size of the part, you only need to modify the part processing program, which is suitable for the development and modification of new products.

②Stable processing quality, high processing accuracy, high repeat accuracy, meeting the processing requirements of aircraft.

③In the case of multi – variety and small – batch production, the production efficiency is relatively high. It can reduce the time for production preparation, machine adjustment, and process inspection. Moreover, due to the use of the optimal cutting amount, the cutting time is reduced.

④It can machine complex surfaces that are difficult to machine by conventional methods, and can even machine some processing parts that cannot be observed.

Custom Aluminum Parts Batch Machining:

If you need help with the machining project of custom aluminum parts, with our expertise in CNC precision machining, we will be one of the most capable and affordable supplier resources for you. We strictly implement the ISO9001 quality system standard, and combined with an efficient production process and flexible customized engineering, we can deliver complex projects in a short turnaround time and provide excellent product quality.

We also provide typical surface treatments for aluminum alloy part machining, such as sandblasting, electroplating, polishing, anodizing, electrophoretic coating, powder coating, painting, etc.

Whether it is automotive manufacturing, medical equipment, or industrial design, we can provide you with accurate and efficient solutions to meet your needs.