CNC boat parts are precision components manufactured via Computer Numerical Control (CNC) machining for marine vessels, designed to withstand harsh aquatic environments—saltwater corrosion, constant vibration, and mechanical stress. These parts, ranging from propeller shafts to deck hardware, balance durability, lightweight design, and tight tolerances, ensuring reliability for recreational boats, yachts, commercial ships, and offshore vessels. CNC machining enables complex, custom shapes critical for performance and safety in marine applications.

Detailed Analysis of CNC Boat Parts

1. Technical Requirements for Marine Environments

Marine environments impose unique demands on boat parts, driving specific technical criteria for CNC machining:

- Corrosion Resistance: Saltwater, humidity, and marine organisms (barnacles, algae) accelerate degradation. CNC parts must resist rust and pitting, requiring materials and finishes that form protective barriers (e.g., passivated stainless steel, anodized aluminum).

- Strength-to-Weight Ratio: Vessels benefit from lightweight components to improve fuel efficiency and maneuverability. CNC machining achieves this by optimizing material distribution—e.g., hollowing structural brackets or thinning non-load-bearing sections without sacrificing strength.

- Precision Fit: Components like propeller shafts or valve housings must align with minimal clearance (±0.02mm) to prevent leaks, reduce friction, and avoid vibration-induced wear. CNC’s high accuracy ensures seamless integration in critical systems (steering, propulsion).

- Impact Resistance: Parts exposed to waves or debris (hull fittings, anchor hardware) need toughness to withstand sudden loads. Machining processes that avoid micro-cracks (e.g., controlled feeds for brittle materials) are prioritized.

2. Key Materials for CNC Boat Parts

Material selection is critical for marine durability, with CNC machining adapted to each substrate’s properties:

-

Stainless Steel (316 & 304):

- 316 Stainless Steel: The gold standard for saltwater environments, containing molybdenum (2–3%) to resist pitting corrosion. Used for propeller shafts, railings, and thru-hull fittings. CNC machining 316 requires carbide tools with high cutting speeds (100–300 m/min) to avoid work hardening, with coolant to flush chips and prevent heat buildup.

- 304 Stainless Steel: Suitable for freshwater or sheltered saltwater (e.g., marinas). Used for non-critical parts like latch hardware or storage brackets, offering good machinability at lower cost than 316.

-

Aluminum Alloys (5052, 6061, 7075):

- 5052 Aluminum: Excellent corrosion resistance in saltwater, used for hull panels, fuel tanks, and lightweight brackets. Its high ductility allows CNC forming of complex curves (e.g., boat console trim).

- 6061 Aluminum: Balances strength and machinability, ideal for structural parts like ladder frames or seat bases. Anodizing (Type III hard anodizing) enhances wear resistance.

- 7075 Aluminum: High-strength (570 MPa tensile strength) for load-bearing components (winch mounts, steering linkage) in performance boats, though less corrosion-resistant than 5052—often coated with epoxy for protection.

-

Bronze Alloys (Naval Brass, Phosphor Bronze):

- Naval Brass (C46400): Resists corrosion and biofouling (marine organism growth), used for propellers, pump impellers, and valve stems. CNC machining bronze requires sharp tools to avoid smearing, with low feeds (50–150 mm/min) for smooth surfaces.

- Phosphor Bronze: High fatigue resistance, suitable for hinges, bushings, and electrical contacts in marine systems (e.g., battery terminals).

-

Composites (Fiberglass, Carbon Fiber Reinforced Polymer/CFRP):

- Used for high-performance parts like hull reinforcements, radar mounts, or racing boat components. CNC routers with diamond-tipped tools cut these materials cleanly, avoiding delamination. CFRP offers exceptional strength-to-weight ratio but requires careful machining to prevent fiber fraying.

3. Common CNC Boat Part Types

CNC machining produces a wide range of marine components, each tailored to functional needs:

-

Propulsion System Parts:

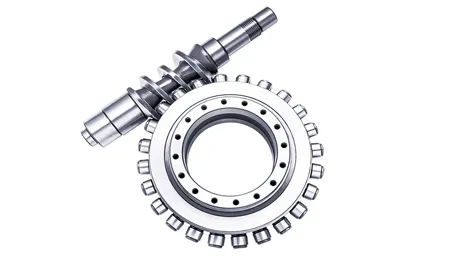

- Propeller Shafts: Machined from 316 stainless steel or nickel-aluminum bronze, with precise concentricity (±0.01mm) to minimize vibration. Keyways and splines are CNC-cut for secure coupling to engines.

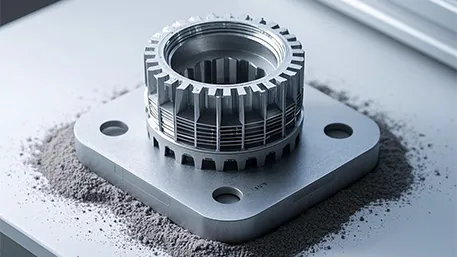

- Impellers & Pump Housings: Bronze or composite parts with intricate vanes, CNC-machined to optimize fluid flow in bilge pumps or cooling systems.

-

Deck & Hull Hardware:

- Railings & Stanchions: 316 stainless steel tubes with CNC-machined end fittings, welded or bolted to decks for safety. Curved sections (e.g., bow railings) are formed via CNC bending.

- Thru-Hull Fittings: 316 stainless steel or bronze components that seal openings for hoses (water intake, exhaust), machined with precise threads and flanges to prevent leaks.

- Cleats & Winches: CNC-machined aluminum or stainless steel fixtures for securing ropes. Winch drums feature precision-grooved surfaces to guide rope evenly.

-

Engine & Systems Components:

- Fuel Manifolds: 6061 aluminum or 316 stainless steel parts with CNC-drilled channels, ensuring even fuel distribution to engines. Smooth internal surfaces (Ra <1.6μm) prevent clogs.

- Steering Linkages: 7075 aluminum or 316 stainless steel rods and joints, machined to tight tolerances for responsive control. Ball joints are CNC-turned for friction-free movement.

-

Electronics & Navigation Mounts:

- Radar & GPS Brackets: CFRP or aluminum parts, CNC-machined to secure equipment while minimizing wind resistance. Custom angles and slots accommodate specific device dimensions.

- Instrument Panels: Aluminum enclosures with CNC-cutouts for gauges, waterproofed via rubber gaskets (grooves machined into panels to seat gaskets).

4. Manufacturing Process for CNC Boat Parts

The production workflow prioritizes corrosion resistance, precision, and durability:

-

Design & Engineering:

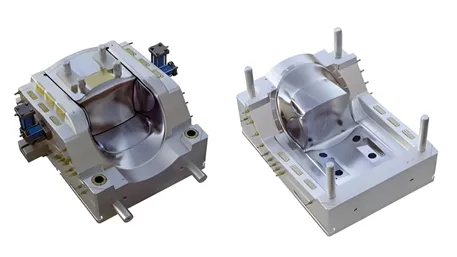

CAD software (SolidWorks, AutoCAD Marine) models parts with marine-specific features—drainage holes to prevent water pooling, rounded edges to resist impact, and material thickness optimized for buoyancy. CAM software (Mastercam Marine) generates toolpaths, accounting for material properties (e.g., slower feeds for bronze to avoid smearing). -

Material Preparation:

Raw stock (stainless steel bars, aluminum sheets) is inspected for marine-grade certification (e.g., ASTM A484 for 316 stainless). Blanks are cut to near-net shape to reduce machining time and material waste. -

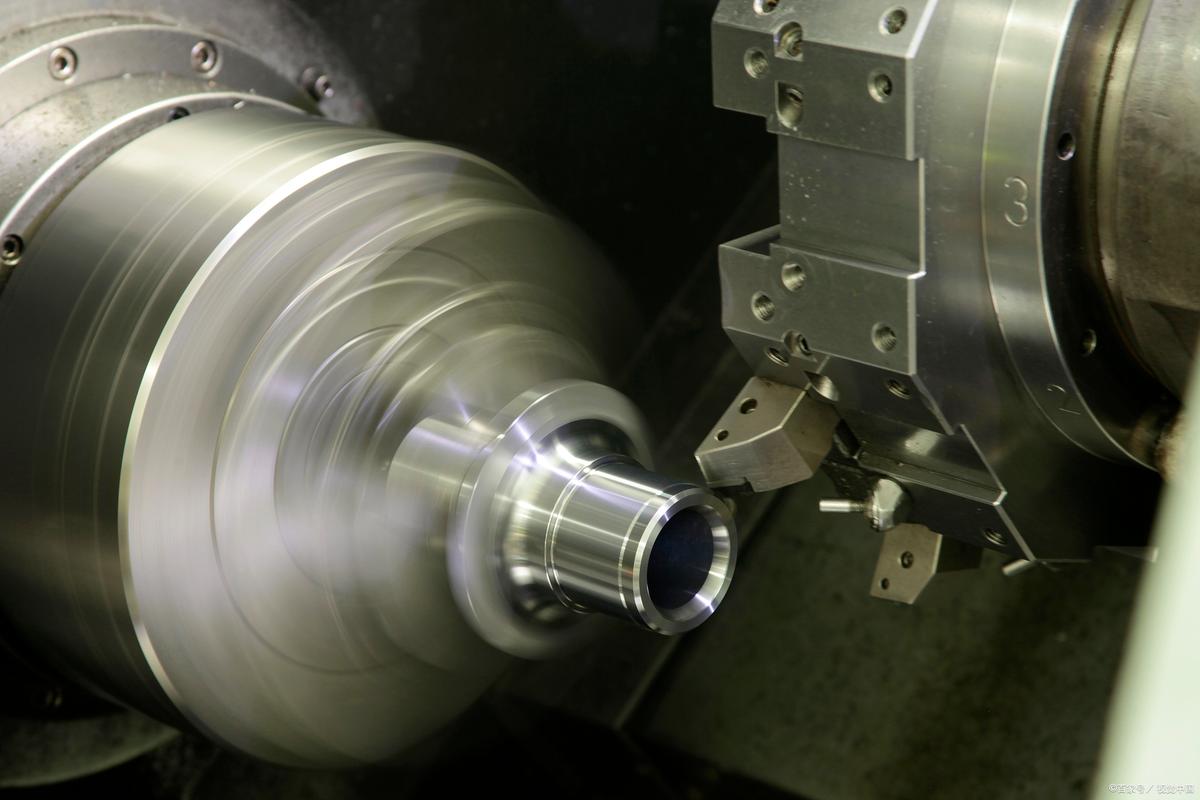

CNC Machining:

- Milling: 3-axis or 5-axis CNC mills shape structural parts (brackets, housings) with features like holes, slots, and contours. For curved railings, 5-axis machines contour 3D shapes in one setup.

- Turning: CNC lathes produce cylindrical parts (shafts, bushings) with precise diameters and threads. Live tooling adds features like keyways or cross-holes without repositioning.

- Finishing: Deburring removes sharp edges (critical for safety), followed by polishing to Ra <0.8μm for stainless steel to enhance corrosion resistance.

-

Corrosion Protection:

- Passivation: Stainless steel parts are treated with nitric acid to remove free iron, forming a protective oxide layer.

- Anodizing: Aluminum parts receive Type II (decorative) or Type III (hard) anodizing, with sealants (e.g., chromic acid) for saltwater exposure.

- Painting/Powder Coating: Steel or aluminum parts may be coated with marine-grade epoxy or polyurethane for added protection, especially in high-wear areas (cleats, winches).

-

Quality Inspection:

- Dimensional Checks: CMMs verify tolerances; optical comparators inspect thread accuracy (e.g., NPT threads for thru-hull fittings).

- Corrosion Testing: Salt spray testing (per ASTM B117) ensures parts resist rust for 500+ hours.

- Strength Testing: Tensile and fatigue tests validate load-bearing parts like steering linkages.

5. Applications Across Marine Sectors

CNC boat parts serve diverse vessels, each with specialized needs:

- Recreational Boating (Yachts, Motorboats): Prioritizes aesthetics and lightweight design. CNC parts include polished stainless steel railings, aluminum console trim, and custom CFRP dash panels.

- Commercial Shipping (Cargo Ships, Ferries): Requires heavy-duty, low-maintenance parts. 316 stainless steel propeller shafts, bronze valves, and reinforced aluminum deck brackets withstand constant use.

- Fishing Vessels: Needs corrosion-resistant parts that resist fish waste and saltwater. CNC-machined 316 stainless steel fish holds, bronze pump components, and aluminum storage racks are common.

- Offshore & Racing Boats: Demands high-performance, lightweight parts. Carbon fiber composite hull reinforcements, 7075 aluminum winch mounts, and precision-machined propellers optimize speed and durability.

- Military & Coast Guard Vessels: Requires rugged, tamper-resistant parts. CNC-machined 316 stainless steel weapons mounts, titanium hardware (for weight reduction), and encrypted electronics enclosures meet strict standards.

6. Challenges & Innovations

- Biofouling: Marine organisms attaching to parts (e.g., propellers) reduce efficiency. Solutions include CNC-machined copper-nickel alloys (inhibits growth) or textured surfaces (disrupts attachment).

- Cost of Marine-Grade Materials: 316 stainless steel and bronze are expensive. Innovations like hybrid parts (aluminum cores with stainless steel cladding) balance cost and performance.

- Vibration Fatigue: Constant engine/vessel movement weakens parts. CNC machining with filleted edges and stress-relief grooves (via FEA simulation) extends fatigue life.

CNC boat parts are essential for marine durability, performance, and safety, combining precision machining with corrosion-resistant materials to thrive in harsh aquatic environments. From recreational yachts to industrial ships, these components ensure reliability, efficiency, and longevity—critical for smooth operations on the water.