Ⅰ.Core Brass Material Properties & Advantages

|

Brass Grade

|

Density (g/cm³)

|

Tensile Strength (MPa)

|

Hardness (HV)

|

Conductivity (IACS%)

|

Salt Spray Resistance (h)

|

Core Advantages

|

Typical Certifications

|

|

H65

|

8.40

|

390

|

100

|

28

|

≥800 (nickel-plated)

|

Easy machining, cost-effective

|

EN 12164

|

|

H70

|

8.50

|

410

|

120

|

26

|

≥1000 (gold-plated)

|

High gloss, low stress corrosion

|

ASTM B134

|

|

HPb59-1

|

8.50

|

420

|

130

|

24

|

≥600

|

Self-lubricating, ideal for complex shapes

|

RoHS

|

|

HSn62-1

|

8.45

|

380

|

110

|

22

|

≥1200

|

Seawater resistance, wear-resistant

|

ISO 4274-1

|

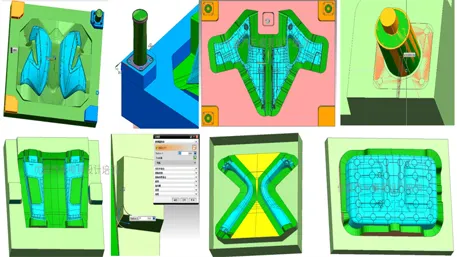

Customization Core Requirements

- Precision Demands: Dimensional tolerance as tight as ±0.005mm (e.g., aerospace connectors), surface roughness Ra≤0.2μm for mirror-finish parts.

- Functional Needs: Electrical contact resistance ≤5mΩ (electronic components), pressure resistance ≥10MPa (hydraulic fittings).

- Environmental Adaptability: Neutral salt spray test ≥720h (outdoor hardware), stable performance at -40℃~120℃ (automotive parts).

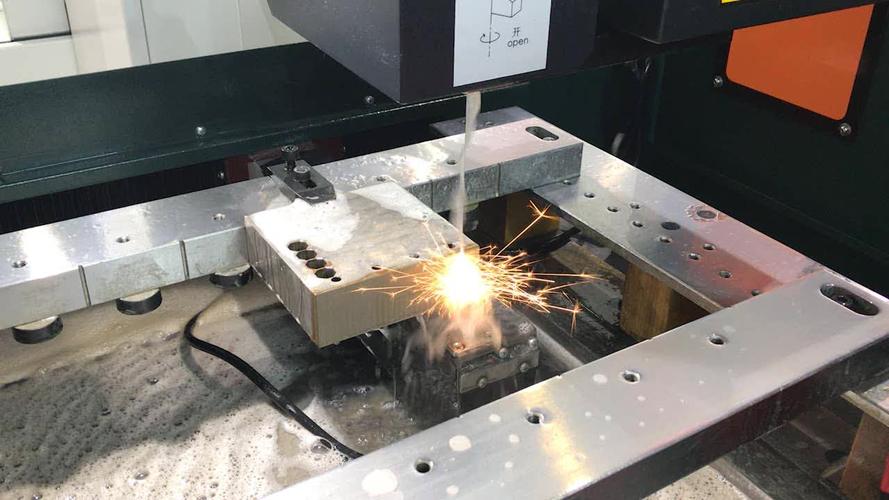

II.Key CNC Machining Technologies for Brass

1. CNC Turning & Milling

- Advantages: 5-axis CNC systems achieve one-step machining of complex geometries (e.g., spiral grooves, eccentric shafts) with accuracy ±0.003mm. For micro-parts (diameter ≥0.5mm, like watch pins), spindle speeds reach 8000-12000rpm.

- Process Parameters: Feed rate 0.05-0.3mm/r, cutting fluid (water-soluble type) to reduce thermal deformation (≤0.003mm).

2. Surface Treatment

|

Process

|

Application

|

Technical Highlights

|

|

Gold/Silver Plating

|

Electronic connectors

|

Plating thickness 0.1-3μm, contact resistance reduced by 30%

|

|

Mirror Polishing

|

Luxury decor

|

Ra≤0.1μm, glossiness ≥90GU

|

|

Passivation

|

Medical parts

|

Chromium-free film (2-5μm), compliant with ISO 13485

|

3. Quality Inspection

- Precision Testing: Coordinate Measuring Machine (CMM) checks geometric tolerances (roundness ≤0.002mm, perpendicularity ≤0.005mm).

- Functional Testing: Tensile tests (yield strength ≥200MPa), helium leak detection (leakage ≤1×10⁻⁹ mbar·L/s for sealed parts).

Ⅲ.End-to-End Customization Process

1. Design & Material Selection

- Structural Optimization: Use FEA (ANSYS) to simulate stress distribution—e.g., optimizing stepped shaft fillets (R≥0.5mm) to extend fatigue life by 40%.

- Material Matching:

-

- Electronics: H70 brass (high conductivity) + gold plating for connectors.

-

- Marine: HSn62-1 (seawater resistance) for shipboard fittings.

2. Production & Delivery

- Rapid Prototyping: 3D-printed brass samples in 24h, CNC first-piece machining in 3 days.

- Mass Production: Automated lines (truss robots) achieve 5000pcs/day for standard parts, with 20% faster delivery via smart scheduling.

3. Quality Assurance

- Tests: Neutral salt spray (≥720h), 冷热循环 (-40℃~80℃, 50 cycles), and wear resistance (≤0.005mm/1000h).

- Certifications: ISO 9001, RoHS, REACH—meeting global market standards.

Ⅳ.Typical Application Scenarios

- Electronics: H70 brass connector pins (CNC turned, gold-plated 3μm) with insertion loss ≤0.1dB (10GHz), adapt to high-density PCBs.

- Automotive: HSn62-1 fuel line connectors (CNC milled) with pressure resistance ≥15MPa, resist gasoline corrosion (volume change ≤2%).

- Medical: HPb59-1 surgical instrument shafts (passivated, Ra≤0.4μm) compliant with USP Class VI, ensure sterilization safety.

- Luxury Goods: H65 brass watch crowns (mirror-polished, rose gold-plated 2μm) with 0.05mm-deep LOGO engraving (accuracy ±0.01mm).

Ⅴ.Technology Selection Guide

|

Requirement Type

|

Preferred Tech Combination

|

Brass Grade

|

Core Indicators

|

Delivery Cycle

|

|

Ultra-Precision Electronics

|

5-axis CNC + Gold Plating

|

H70

|

±0.005mm, ≤3mΩ

|

5 days (proto), 25 days (mass)

|

|

Marine Corrosion-Resistant

|

CNC Milling + Passivation

|

HSn62-1

|

≥1200h salt spray

|

7 days (proto), 30 days (mass)

|

|

Luxury Decor

|

Precision Turning + Polishing

|

H65

|

≥90GU glossiness

|

6 days (proto), 28 days (mass)

|