In the dynamic landscape of modern manufacturing, CNC custom machining of milling and turning parts stands as a cornerstone of precision engineering. By harnessing the capabilities of Computer Numerical Control (CNC) technology, we deliver components with unparalleled accuracy, consistency, and efficiency. This article explores the technical prowess, customization process, material versatility, quality control measures, and industry applications of CNC custom machining for milling and turning parts, highlighting its pivotal role in driving innovation across diverse sectors.

I. Technical Capabilities: Precision Redefined

(A) Micron – Level Dimensional Accuracy

CNC milling and turning centers are calibrated to achieve extraordinary dimensional precision, with positioning accuracy reaching ±0.002mm and repeatability within ±0.001mm. This allows for the production of components with intricate geometries, such as multi – stepped shafts, helical gears, and complex valve bodies, where tolerances as tight as ±0.005mm are routinely maintained. For example, in aerospace applications, CNC – machined turbine blades require sub – micron precision to ensure optimal aerodynamic performance and material integrity under extreme conditions.

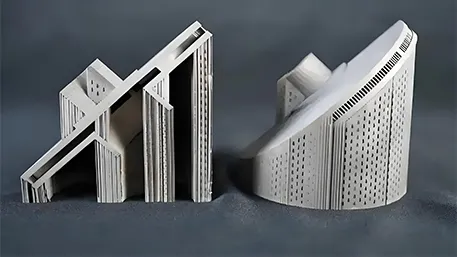

(B) Complex Geometry Machining

Our 5 – axis CNC milling and turning systems excel at producing parts with complex contours, internal features, and asymmetrical designs. By integrating advanced toolpath strategies and real – time adaptive control, we reduce setup errors by up to 85% compared to conventional methods. This capability is critical for manufacturing components like medical implants with organic shapes or automotive transmission housings with intricate internal channels, where traditional machining techniques would be impractical.

(C) High – Speed Machining for Enhanced Productivity

Leveraging spindle speeds up to 30,000 RPM and rapid traverse rates exceeding 60m/min, our CNC platforms achieve material removal rates up to 40% higher than conventional machining. This efficiency is further amplified by automated tool changers and pallet systems, enabling uninterrupted production runs. For instance, in mass – producing aluminum heat sinks for electronics, our CNC turning processes reduce cycle times by 35% while maintaining surface finishes of Ra 0.8μm.

II. End – to – End Customization: From Concept to Reality

(A) Collaborative Design Engineering

Our process begins with in – depth consultations to understand your application requirements, including load profiles, environmental conditions, and assembly constraints. Using 3D modeling and finite element analysis (FEA), we optimize part geometries for manufacturability and performance. For example, when developing a titanium alloy impeller for marine applications, our engineers simulate fluid dynamics to refine blade profiles, ensuring maximum efficiency while minimizing cavitation.

(B) Material Selection Expertise

We offer a comprehensive range of materials, from aluminum 6061 – T6 (tensile strength 310 MPa) and stainless steel 316L (corrosion – resistant in marine environments) to exotic alloys like Inconel 718 (withstanding temperatures up to 700°C). For high – precision applications, we recommend aerospace – grade 4140 alloy steel, heat – treated to achieve a Rockwell hardness of C40 – 45, ensuring optimal wear resistance in critical components.

(C) Agile Manufacturing Workflow

Once designs are finalized, our production team deploys lean manufacturing principles to minimize lead times. Advanced CNC programming with toolpath optimization reduces machining time by 20 – 30% compared to standard methods. Real – time monitoring via IoT – enabled machines ensures process stability, with automated alerts for deviations from tolerance thresholds, guaranteeing consistent quality across production runs.

(D) Comprehensive Quality Assurance

Every component undergoes rigorous inspection using coordinate measuring machines (CMM) and optical profilometers. For critical aerospace parts, we perform X – ray diffraction analysis to verify material grain structure integrity. Our quality management system is ISO 9001:2015 certified, with traceability documentation available for every lot, ensuring compliance with AS9100D and other industry standards.

III. Strategic Material Selection: Matching Properties to Performance

(A) Aluminum Alloys

Ideal for lightweight applications, aluminum 7075 – T6 offers a strength – to – weight ratio comparable to steel, with a tensile strength of 572 MPa and density of 2.81 g/cm³. Commonly used in automotive suspension components and drone frames, its machinability allows for intricate designs while maintaining structural integrity.

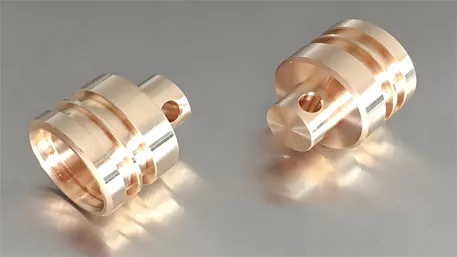

(B) Stainless Steels

For corrosion – prone environments, 316L stainless steel provides exceptional resistance to chlorides and acids. With a yield strength of 215 MPa and elongation up to 40%, it is ideal for medical implants and food processing equipment, where biocompatibility and hygiene are critical.

(C) Titanium Alloys

Titanium Grade 5 (Ti – 6Al – 4V) combines high strength (ultimate tensile strength 900 MPa) with low density (4.43 g/cm³) and excellent corrosion resistance. Widely used in aerospace components and surgical instruments, its biocompatibility makes it suitable for long – term implantation in the human body.

(D) Engineering Plastics

For non – metallic applications, PEEK (polyetheretherketone) offers high – temperature resistance (melting point 343°C), chemical inertness, and inherent flame retardancy. CNC – machined PEEK components are used in semiconductor manufacturing equipment, where purity and dimensional stability are paramount.

IV. Industry Applications: Driving Innovation Across Sectors

(A) Aerospace and Defense

CNC – machined components such as landing gear parts, engine mounts, and avionics housings demand extreme precision and reliability. Our titanium alloy turbine blades, machined to within ±0.003mm tolerance, ensure optimal airflow and reduce fuel consumption by up to 12% in modern jet engines.

(B) Medical Device Manufacturing

From orthopedic implants to surgical instruments, CNC machining enables the production of complex geometries with sub – micron accuracy. For example, our custom – machined titanium spinal fusion cages feature porous surfaces to promote bone integration, while internal channels optimize drug delivery for post – operative care.

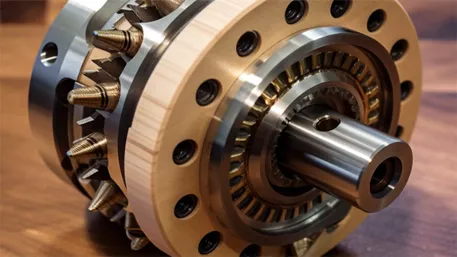

(C) Robotics and Automation

Precision gears, shafts, and joints produced via CNC turning and milling are critical for robotic arm functionality. Our aluminum alloy components, with surface finishes as low as Ra 0.4μm, reduce friction and enable repeatable motion control within ±0.01°, essential for tasks like micro – assembly in electronics manufacturing.

(D) Renewable Energy

In wind turbine systems, CNC – machined gearbox components such as helical gears and planetary carriers must withstand cyclic loads exceeding 100 MPa. Using 4340 alloy steel heat – treated to 300 – 350 BHN, we achieve fatigue life improvements of over 50% compared to conventional manufacturing methods.

V. Case Studies: Transforming Complex Challenges into Precision Solutions

(A) Satellite Communication System

A leading aerospace firm required custom – machined microwave waveguides with internal contours adhering to RF specifications. Using 5 – axis CNC milling, we achieved surface roughness of Ra 0.2μm on aluminum 6061, minimizing signal loss and ensuring compliance with MIL – STD – 1540E standards for space applications.

(B) High – Performance Racing Engine

For a Formula 1 team seeking to optimize engine efficiency, we CNC – turned titanium connecting rods with a wall thickness of 1.2mm ±0.005mm. This reduced reciprocating mass by 18%, improving acceleration response while maintaining fatigue resistance under 20,000 RPM operation.

(C) Surgical Robot Component

A medical technology startup needed a stainless steel 316L articulation joint for a minimally invasive surgical system. Our CNC machining process achieved a 0.001mm surface finish on mating surfaces, eliminating the need for post – processing and ensuring smooth, backlash – free movement critical for precise surgical maneuvers.

VI. Frequently Asked Questions

(A) What is the typical lead time for CNC custom machining projects?

Simple components can be delivered in 3 – 5 business days, while complex multi – operation parts may take 10 – 15 days. Expedited services are available for urgent requirements, with 48 – hour turnaround options for prototyping.

(B) How do you handle design modifications during production?

Our flexible manufacturing system allows real – time adjustments to CNC programs. For minor changes, we can often implement modifications within a single production cycle, minimizing delays and cost overruns.

(C) What is the minimum order quantity (MOQ)?

We accommodate orders from single prototypes to high – volume production runs exceeding 100,000 units. Our modular tooling and quick – change setups ensure cost – effectiveness across all scales.

(D) Can you machine exotic materials like Inconel or Hastelloy?

Yes, our advanced CNC platforms are equipped with specialized cutting tools and coolant systems optimized for high – temperature alloys. We routinely machine materials with hardness up to 60 HRC, maintaining dimensional accuracy within ±0.005mm.

(E) What certifications do you hold?

We are ISO 9001:2015 and AS9100D certified, with additional compliance for medical device manufacturing (ISO 13485) and automotive (IATF 16949). Our facilities adhere to ITAR and EAR regulations for defense – related components.

VII. Why Choose Our CNC Custom Machining Services?

- Uncompromising Precision: ±0.002mm tolerance capability across diverse materials

- Advanced Technology: 5 – axis machining centers and real – time adaptive control systems

- Material Expertise: 100 + materials supported, from aluminum to superalloys

- Scalability: Seamless transition from prototyping to mass production

- Sustainability: Optimized toolpaths reduce material waste by up to 25% compared to conventional methods

Ready to Transform Your Project?

Our team of engineers and machinists stands ready to collaborate on your next precision component. Contact us today to discuss your requirements and receive a customized solution tailored to your exact specifications.

Our team of engineers and machinists stands ready to collaborate on your next precision component. Contact us today to discuss your requirements and receive a customized solution tailored to your exact specifications.