In today’s fast-changing technology, the manufacturing industry is experiencing an unprecedented change. In this change, CNC (Computer Numerical Control) machining technology with its unparalleled precision, efficiency and flexibility, has become an important force to promote the development of modern industry. CNC machined parts, as a direct product of this technology, is leading the precision manufacturing into a new era of science and technology.

1.CNC machining technology: the precise art of digital control

CNC machining technology, in short, is the use of computer programs to control machine tools for automated machining processes. This technology realizes precise control of the machining process by converting design drawings into machine-readable codes (usually G-code and M-code). In this process, every action of the machine tool, including tool trajectory, cutting speed, feed, etc., is carried out in strict accordance with the preset program, thus ensuring a high degree of consistency and accuracy of the machined parts.

The core of CNC machining technology lies in its digital control system. This system not only has a strong computing power, able to handle complex processing instructions, but also has a high degree of stability and reliability, able to maintain high-precision machining over a long period of time. In addition, with the continuous progress of computer technology, CNC machining technology is also constantly updated and iterative, the introduction of more intelligent features, such as automatic compensation, fault diagnosis and remote monitoring, further improving the processing efficiency and processing quality.

2.CNC machining parts: a model of precision manufacturing

CNC machined parts are famous for their high precision, high complexity and high consistency. In the aerospace field, CNC machining technology can produce engine blades and fuselage structural parts with complex shapes and high precision; in the automotive industry, CNC machined parts are widely used in the production of engine blocks, crankshafts, transmission gears and other key components; and in the field of medical devices, CNC machining technology provides strong support for the manufacture of surgical instruments, implants and other high-precision medical devices. CNC machining technology provides strong support for the manufacture of surgical instruments, implants and other high-precision medical devices.

3.Advantages of CNC machining parts

Multi-axis linkage machining: CNC machine tools are equipped with multi-axis linkage function, capable of controlling the movement of multiple axes at the same time, so as to realize the machining of complex curved surfaces and shaped structures. This ability makes CNC machining technology easy to handle complex parts.

High-precision control: CNC machining technology is usually controlled at the micron level or even higher, and is able to meet the application scenarios that require very high precision. This high precision control capability is an integral part of modern manufacturing.

Highly efficient production: CNC machining technology greatly improves production efficiency through automated programming and control, which reduces manual intervention and waiting time. At the same time, CNC machines can run continuously and automatically, making them suitable for high-volume production and further shortening the production cycle.

High Flexibility: CNC machining technology is highly flexible, able to quickly adjust the machining parameters and programs to adapt to different batches and multiple varieties of production needs. This flexibility makes CNC machining technology in the modern manufacturing industry has been widely used.

4. CNC machining parts application scene

4.1 Aerospace field

In the aerospace field, CNC machining technology plays a vital role. Aircraft engine blades, fuselage structural parts, landing gear and other key components need to be manufactured using CNC machining technology. These parts not only have complex shapes, but also require high precision and strength, CNC machining technology can ensure the precision and consistency of these parts, thus improving the overall performance and safety of the aircraft.

4.2 Automobile Industry

CNC machining technology is also widely used in the automobile industry. From the engine block, crankshaft, connecting rod to transmission gears, body structure parts, CNC machining technology plays an important role. The machining accuracy of these parts directly affects the performance and reliability of the car, CNC machining technology through high-precision control and multi-axis linkage function, to realize the accurate processing of these parts, improve the overall quality of the car.

4.3 Medical Equipment

Medical equipment has extremely high requirements for precision and cleanliness, and CNC machining technology can produce precision parts that meet these requirements, such as surgical instruments, implants, endoscopic parts, etc. These parts play an important role in the medical process. These parts play a key role in the medical process, which is directly related to the safety and treatment effect of patients, CNC machining technology ensures the high precision and reliability of these parts through strict quality control and inspection process.

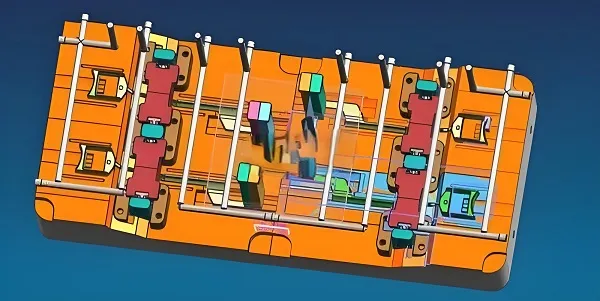

4.4 Mold Manufacturing

Mold is an important tool in the manufacturing industry, and its precision and quality directly affect the quality of the final product.CNC machining technology plays an important role in the manufacturing of molds, and is able to process mold parts with high precision and high complexity. These mold parts are widely used in the production of automotive, electronics, home appliances and other industries, promoting the rapid development of these industries.

4.5 Electronic equipment manufacturing

With the continuous upgrading of electronic products, the precision and stability requirements of the parts are getting higher and higher, CNC machining technology can meet these requirements and provide high-quality parts for electronic equipment manufacturers. For example, circuit boards, cell phone shells, precision connectors, etc. can be produced by CNC machining technology. The accuracy and stability of these parts are directly related to the performance and reliability of electronic products.