Computer Numerical Control (CNC) machining, as a pillar technology of modern manufacturing, has evolved from simple automation in the mid-20th century to the core of intelligent production today. It precisely controls machine tools through computer programs to perform cutting, milling, drilling and other operations on metals, plastics and other materials, helping countless projects transition seamlessly from concept to finished product.

According to industry data, the global CNC market size reached approximately \(90 billion in 2025 and is expected to exceed \)110 billion by 2030, with a compound annual growth rate (CAGR) of about 4%.

For users in Europe and America, searching for “CNC machining basics” or “precision CNC applications” often stems from practical needs: engineers in automotive, aerospace, and medical fields seek efficient prototyping, while small and medium-sized business owners focus on cost optimization. This article will start with basic knowledge, explain CNC core principles, common pain points, and 2025 trends, combined with Xiamen Goldcattle’s 26 years of professional experience, to help you quickly get started with precision manufacturing.

CNC Machining Fundamentals: From Principles to Daily Applications

What is CNC? A Simple Breakdown

Imagine a machine tool like an “obedient artist”: it carves complex shapes on materials according to digital instructions. This is the essence of CNC – Computer Numerical Control. Unlike manual operations, CNC uses G-code (a programming language) to guide axial movements: X, Y, Z axes control linear displacement, and A, B, C axes handle rotation.

Core Components:

- Worktable (material fixation)

- Controller (running software such as Mastercam or Fusion 360)

Entry-level 3-axis CNC is suitable for planar machining, while 5-axis systems can handle 3D curved surfaces, widely used in turbine blade production in the European and American automotive industries.

Workflow:

- CAD design modeling

- CAM generation of tool paths

- Machine tool execution with real-time feedback

The entire process can control tolerances within ±0.01mm, far exceeding manual precision.

3-axis CNC vs 5-axis CNC Comparison

European and American reading habits prefer concise and practical content: according to Pew Research data, 48% of American adults read more than 7 hours per week, but favor content with charts and lists.

|

Aspect

|

3-axis CNC

|

5-axis CNC

|

|

Application Scenarios

|

Planar parts (brackets, hardware accessories)

|

Complex curved surfaces (aerospace blades, automotive components)

|

|

Machining Efficiency

|

Basic, requires multiple rotations

|

Single clamping, time reduced by 30-50%

|

|

Cost

|

Entry-level equipment \(50,000-\)100,000

|

Advanced equipment $200,000+, but faster ROI

|

|

Xiamen Goldcattle Applications

|

Motorcycle parts, hardware accessories

|

Automotive components, mechanical parts, equipment parts

|

This technology not only improves efficiency but also reduces waste: traditional machining waste rates can reach 20%, while CNC optimization reduces it to below 5%.

Materials and Application Fields

Main Machining Materials

Xiamen Goldcattle, as a professional CNC machining service provider, can handle various materials:

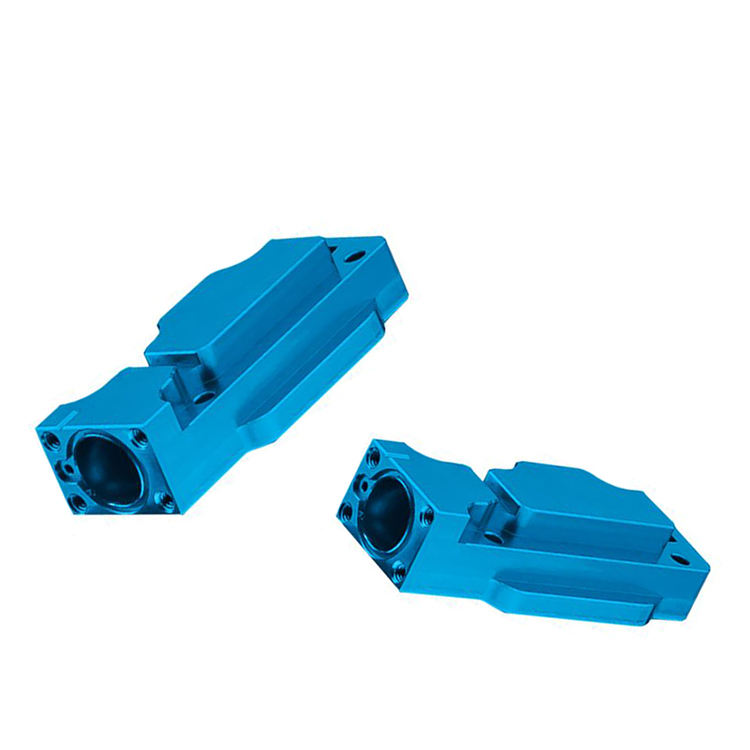

- Aluminum Alloy: Lightweight, good thermal conductivity, widely used in automotive and aerospace

- Stainless Steel/Steel: High strength, corrosion resistance, suitable for mechanical parts and medical equipment

- Copper/Brass: Good conductivity, aesthetic appearance, used in electronic parts and decorative items

- Plastic/Rubber: Low cost, lightweight, suitable for various equipment housings and accessories

Core Application Fields

Based on 26 years of industry experience, Xiamen Goldcattle’s CNC machining services cover multiple key areas:

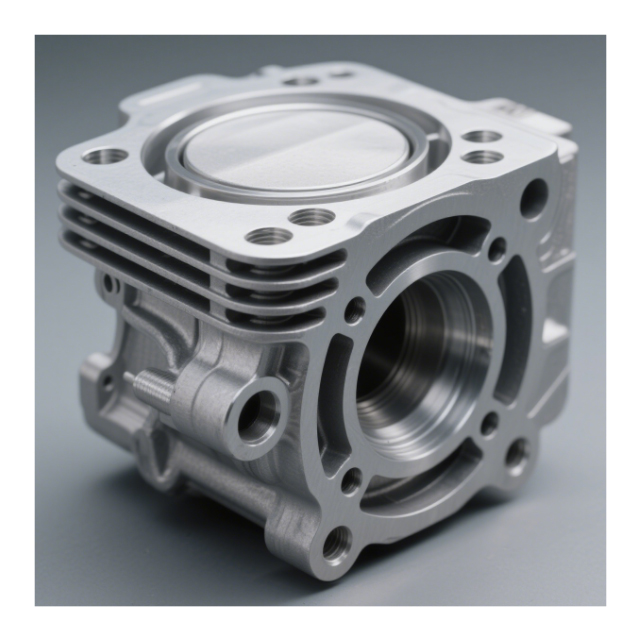

Automotive Components:

- Customized according to customer requirements, precisely matching automotive specifications

- Applied to engines, transmission systems, suspension systems and other key components

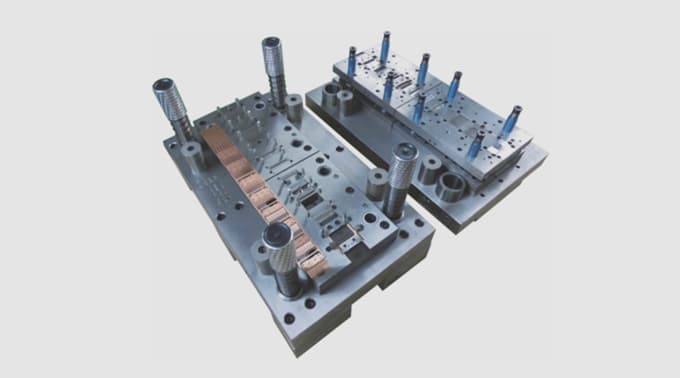

Mechanical Parts:

- Individually customized mechanical parts to adapt to various working conditions

- High-precision manufacturing ensures stable equipment operation

Motorcycle Parts:

- Customized according to riding needs to meet personalized requirements

- Perfect combination of performance and aesthetics

Hardware Parts:

- Exclusively crafted hardware components, precisely tailored to fit usage scenarios

- Widely used in construction, furniture, electronic equipment, etc.

Equipment Parts:

- Tailor-made parts that precisely match equipment requirements

- Ensure efficient operation and long service life of equipment

Common Pain Points and Solutions

Google search data shows that “CNC machining problems” related queries increased by 15% in 2025, with European and American users’ pain points concentrated on precision loss, material compatibility, and delivery delays.

Typical Problems and Solutions

1. Precision Control Issues

- Challenge: Precision deviations in complex part machining

- Solution: Xiamen Goldcattle adopts advanced testing equipment and strict quality control processes to ensure tolerance control within ±0.01mm

2. Material Deformation Problems

- Challenge: Materials like aluminum alloy are prone to deformation during machining

- Solution: Professional cooling systems and machining simulation software to predict thermal stress, combined with 26 years of experience to optimize machining parameters

3. Long Delivery Cycles

- Challenge: Rapid response requirements for emergency orders

- Solution: Xiamen Goldcattle promises to respond to customer inquiries within 24 hours, establishing an efficient production scheduling system to ensure on-time delivery

4. Sustainability Requirements

- Challenge: Compliance with environmental regulations such as EU REACH

- Solution: Integration of environmentally friendly tools and machining processes, reducing energy consumption by 20%, meeting international environmental standards

2025 CNC Trends: AI and Customization Driving Innovation

Looking ahead to 2025, CNC is deeply integrating with AI, responding to the search peak for “intelligent CNC manufacturing”. Below are three major user-centric trends, combined with Xiamen Goldcattle’s practical applications:

1. AI-Optimized Tool Paths

Traditional paths rely on manual work and are prone to inefficiency. AI algorithms (such as machine learning models) analyze historical data to predict optimal cutting angles, reducing tool wear by 15%. Xiamen Goldcattle is actively introducing this technology, expecting to shorten prototype cycles from weeks to days.

2. Hybrid Manufacturing: CNC + 3D Printing

Not limited to subtractive manufacturing, CNC can be combined with additive manufacturing to achieve “zero waste” production. Xiamen Goldcattle has integrated 3D printing technology to provide customers with one-stop services from prototype design to mass production, especially suitable for rapid manufacturing of complex geometries.

3. Predictive Maintenance and IoT

Sensors monitor vibration and temperature in real-time to prevent failures. Data shows this trend will inject $2.5 billion in growth into the high-performance CNC market. Xiamen Goldcattle is gradually deploying intelligent monitoring systems, shifting from “passive maintenance” to “proactive optimization” to minimize downtime.

Xiamen Goldcattle’s Professional Service Process

Based on 26 years of industry experience, Xiamen Goldcattle has established a standardized service process:

- Consultation: Customers provide requirements and design drawings

- Factory Quotation: Provide detailed quotation and technical proposal within 24 hours

- Sample Confirmation: Produce samples and obtain customer confirmation

- Order Payment: Confirm order and arrange production

- Mass Production: Efficient production to ensure on-time delivery

- Delivery: Safe packaging and timely delivery

Corporate Advantages:

- 26 years of professional experience serving global customers

- National-level high-tech enterprise qualification

- One-stop solution: full-process service from design to production

- Strict quality control system

- Rapid response: customer inquiries replied within 24 hours

Practical Insights: How to Start Your CNC Journey

The charm of CNC lies in its accessibility: open-source software like FreeCAD makes the entry barrier zero, but professional customization is the key to advancement.

Recommended Starting Steps

- Clarify Requirements: Determine the type of parts, materials, and precision requirements you need to machine

- Prepare Designs: Use CAD software to design 3D models or provide 2D drawings

- Choose a Partner: Select an experienced CNC machining service provider like Xiamen Goldcattle

- Sample Confirmation: Produce samples first for testing and confirmation

- Mass Production: Proceed to mass production after sample confirmation

Successful Case Studies

Automotive Industry Case:

An American automotive supplier reduced gear production costs by 10% through Xiamen Goldcattle’s AI path optimization technology, while improving product precision and consistency.

Medical Equipment Case:

A European medical project benefited from Xiamen Goldcattle’s REACH-compliant titanium alloy customization service, with products passing strict medical certifications and successfully applied to surgical instruments.

Mechanical Equipment Case:

A German machinery manufacturer shortened the production cycle of complex parts by 40% through Xiamen Goldcattle’s 5-axis CNC machining service, significantly enhancing market competitiveness.

Conclusion

CNC machining technology is developing towards smarter, more efficient, and more environmentally friendly directions. Xiamen Goldcattle, as a professional CNC machining service provider with 26 years of experience, always adheres to the philosophy of “high quality, high efficiency, integrity, and service”, committed to providing the highest quality precision manufacturing solutions for global customers.

Which aspect of CNC are you most interested in? Is it basic programming, trend applications, or specific material selection? Welcome to share your questions or experiences in the comment section – based on community feedback, we will provide more targeted content.

Visit Xiamen Goldcattle’s official website (https://www.xmgoldcattle.com/) to get free CNC machining consultation. Our professional team will provide you with detailed solutions within 24 hours to jointly ignite manufacturing innovation.