Introduction

In modern manufacturing, CNC machining and additive manufacturing have emerged as two pivotal technologies, each with its own set of unique characteristics and applications. CNC machining, with its roots firmly planted in traditional subtractive manufacturing processes, has long been the go – to method for producing high – precision parts with a high degree of consistency. It has been the backbone of industries such as aerospace, automotive, and medical device manufacturing, where precision and reliability are of utmost importance.

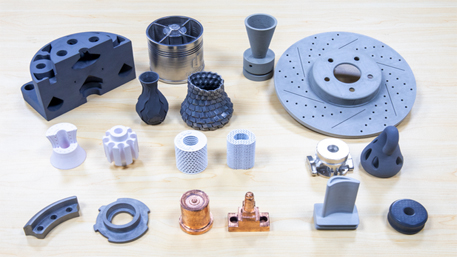

On the other hand, additive manufacturing, more commonly known as 3D printing, represents a revolutionary approach to manufacturing. It has disrupted the traditional manufacturing paradigm by enabling the creation of complex geometries that were previously impossible or extremely difficult to produce using conventional methods. This technology has opened up new possibilities in rapid prototyping, customized production, and the development of innovative product designs.

Given their significance in the manufacturing landscape, a comprehensive comparison between CNC machining and additive manufacturing is not only timely but also essential. In the following sections, we will delve deep into the technical aspects, applications, cost – effectiveness, and future prospects of these two manufacturing powerhouses.

1. What is CNC Machining?

1.1 Definition and Basics

CNC machining, short for Computer Numerical Control machining, is a subtractive manufacturing process. It involves using pre – programmed computer software to control the movement of factory tools and machinery. In this process, a block of raw material, such as metal, plastic, or wood, is gradually shaped into the desired final product by removing excess material through various cutting operations. This is in contrast to additive manufacturing, which builds objects layer by layer.

For example, in the production of a complex engine part for an automobile, a solid block of aluminum alloy is used as the starting material. Through CNC machining, the excess aluminum is precisely removed to create the intricate shape required for the engine part, ensuring a perfect fit and high – performance operation within the engine.

1.2 Working Principles

The working principle of CNC machining centers around the use of numerical control programming. First, a CAD (Computer – Aided Design) model of the part to be manufactured is created. This 3D model contains all the geometric information of the final product. Then, a CAM (Computer – Aided Manufacturing) software is used to convert the CAD model into a set of instructions in the form of G – codes and M – codes. These codes are the language that the CNC machine understands.

Once the program is ready, it is transferred to the CNC machine’s control system. The control system then commands the movement of the machine’s axes. Most CNC machines have at least three axes: X, Y, and Z, which correspond to the length, width, and height directions in a three – dimensional space. Some advanced CNC machines can have up to five or even more axes.

The movement of these axes precisely controls the relative position between the cutting tool and the workpiece. For instance, in a milling operation, the spindle rotates the cutting tool at a high speed, while the axes move the workpiece in a coordinated manner to create the desired shape, such as milling a slot or a contour on the surface of the workpiece.

1.3 Key Components and Machinery

Spindle: The spindle is a crucial component of a CNC machine. It holds and rotates the cutting tool at high speeds. The speed of the spindle can be precisely controlled according to the requirements of the machining operation. For high – speed milling of soft materials like aluminum, the spindle may rotate at speeds of up to 20,000 RPM or even higher, while for rough machining of hard metals such as steel, a lower spindle speed, perhaps around 1000 – 3000 RPM, might be more appropriate.

Worktable: The worktable is where the workpiece is securely fastened. It can move along the X, Y, and sometimes Z axes, allowing for precise positioning of the workpiece relative to the cutting tool. In some CNC machines, the worktable can also rotate, adding an additional degree of freedom for more complex machining operations. For example, in five – axis machining centers, the worktable can rotate around two axes, enabling the machining of complex curved surfaces.

tool magazine: A tool magazine, also known as a tool changer or a tool carousel, stores multiple cutting tools. It allows the CNC machine to automatically change tools during the machining process. This is essential for performing multiple operations on a single workpiece without the need for manual tool changes. For example, a typical CNC machining center might have a tool magazine that can hold 20 – 30 different tools, such as end mills, drills, and reamers. When the machining program calls for a specific tool, the tool magazine rotates to position the required tool at the tool – change position, and the machine’s automatic tool – change mechanism then replaces the current tool with the new one.

control system: The control system is the brain of the CNC machine. It interprets the G – codes and M – codes from the CAM program and sends commands to the various components of the machine, such as the spindle, axes, and tool magazine. Modern CNC control systems are highly advanced and can perform complex calculations in real – time to ensure accurate and smooth machining operations. They also often have features like error – detection and self – diagnosis, which can quickly identify and report any issues during the machining process.

2. What is Additive Manufacturing?

2.1 Definition and Basics

Additive manufacturing, more commonly known as 3D printing, is a revolutionary manufacturing process. It is a technology that builds three – dimensional objects by adding layer upon layer of material based on three – dimensional model data. In contrast to traditional subtractive manufacturing methods like CNC machining, additive manufacturing starts from scratch, gradually building up the object.

For example, in the creation of a custom – designed dental crown, a 3D scanner first captures the patient’s tooth structure, creating a digital 3D model. Then, using additive manufacturing, a biocompatible ceramic or plastic material is deposited layer by layer to form the exact shape of the dental crown, tailored to the patient’s specific needs.

2.2 Working Principles

The working process of additive manufacturing generally involves the following steps:

3D Model Design: First, a 3D model of the object to be printed is created using CAD software. This model serves as the blueprint for the entire manufacturing process. For instance, an industrial designer might use CAD software to design a complex mechanical part with intricate internal channels for fluid flow.

Data Processing and Slicing: The 3D model is then processed by specialized software. This software slices the 3D model into numerous thin layers, typically with a thickness ranging from a few micrometers to a few millimeters. Each slice contains detailed information about the cross – sectional shape of the object at that particular level. For example, if printing a small figurine, the software will slice the 3D model of the figurine into hundreds of thin layers, each representing a different cross – section of the figurine’s body.

Layer – by – layer printing: The additive manufacturing machine reads the sliced data and starts depositing materials layer by layer according to the instructions. Different additive manufacturing technologies use various methods to deposit materials. For example, in Fused Deposition Modeling (FDM), a common additive manufacturing technology, a thermoplastic filament is melted and extruded through a nozzle to form each layer. As the nozzle moves in the X – Y plane, it deposits the molten material in the shape defined by the slice data. After one layer is completed, the build platform moves down (or the nozzle moves up) by the thickness of one layer, and the next layer is printed on top of the previous one.

Post – processing: After the printing process is complete, the printed object usually requires some post – processing steps. This may include removing any support structures that were used during the printing process to hold up overhanging parts of the object. For example, if the printed object has a large, overhanging section, support structures were likely printed underneath it to prevent it from collapsing during the printing process. These support structures are typically made of a different material or a different form of the same material and can be removed by hand, dissolved in a solvent (if the support material is soluble), or broken off. Post – processing may also involve sanding, polishing, or coating the printed object to improve its surface finish and appearance. For example, a printed metal part may be sandblasted to give it a smooth surface finish or coated with a protective layer to prevent corrosion.

2.3 Common AM Technologies

FDM – Fused Deposition Modeling: In FDM, a spool of thermoplastic filament, such as ABS (Acrylonitrile Butadiene Styrene) or PLA (Polylactic Acid), is fed into a heated extruder nozzle. The nozzle melts the filament and deposits it layer by layer on the build platform. FDM is popular for its relatively low cost, simplicity, and wide availability of materials. It is often used in educational settings, hobbyist projects, and for creating simple prototypes. For example, a student might use an FDM printer to create a 3D – printed model of a mechanical gear for a school project. One of the limitations of FDM is that it generally has a lower resolution compared to some other AM technologies, resulting in a more visible layer – by – layer texture on the printed object.

SLA – Stereolithography Apparatus: SLA uses a laser to cure a liquid photopolymer resin layer by layer. A vat is filled with the liquid resin, and a movable platform is initially positioned just below the surface of the resin. The laser traces the cross – sectional shape of the first layer onto the resin surface, causing the resin to solidify. After each layer is cured, the platform is lowered, and a new layer of resin is spread over the previously cured layer. SLA offers high precision and smooth surface finishes, making it suitable for applications such as jewelry design, dental model making, and the production of highly detailed prototypes. For example, a jewelry designer can use SLA to create a detailed wax – like prototype of a complex jewelry piece, which can then be used for casting precious metals. However, SLA printers and materials tend to be more expensive, and the resin materials can be sensitive to light and require proper storage.

SLS – Selective Laser Sintering: SLS uses a high – power laser to sinter powdered materials, such as plastic, metal, or ceramic powders. The powder is spread evenly across a build platform, and the laser selectively heats and fuses the powder particles together according to the cross – sectional shape of each layer. SLS can produce parts with complex geometries and good mechanical properties. It is commonly used in industries like automotive and aerospace for manufacturing functional prototypes and end – use parts. For example, in the automotive industry, SLS can be used to create lightweight, complex – shaped interior components with optimized strength – to – weight ratios. One advantage of SLS is that it doesn’t require support structures for most geometries, as the unsintered powder supports the overhanging parts during the printing process. But SLS equipment is expensive, and the post – processing of removing the unsintered powder can be time – consuming.

SLM – Selective Laser Melting: SLM is similar to SLS but is mainly used for metal additive manufacturing. It uses a high – energy laser to fully melt metal powder particles layer by layer, creating fully dense metal parts. SLM is capable of producing highly complex metal components with excellent mechanical properties. It is widely applied in the aerospace and medical industries. In aerospace, SLM can be used to manufacture lightweight, high – strength titanium alloy parts for aircraft engines. In the medical field, it can be used to create customized implantable devices, such as patient – specific orthopedic implants. However, SLM requires a controlled environment (usually an inert gas atmosphere) to prevent oxidation during the melting process, and the cost of equipment and materials is relatively high.

3. Comparison of CNC Machining and Additive Manufacturing

3.1 Precision and Accuracy

CNC machining is renowned for its high precision and accuracy. In many cases, it can achieve tolerances in the range of ±0.001 – ±0.01 mm, depending on the type of CNC machine and the complexity of the operation. This makes it the ideal choice for industries where tight tolerances are crucial, such as aerospace and medical device manufacturing. For example, in the production of aircraft engine components, the high – precision requirements for the fit and function of parts demand the use of CNC machining to ensure that each component meets the strictest quality standards.

On the other hand, the precision and accuracy of additive manufacturing vary depending on the technology used. Some advanced additive manufacturing processes, like SLA, can achieve high levels of precision, with layer thicknesses as low as 25 – 50 microns, allowing for the production of parts with fine details. However, in general, additive manufacturing may have limitations in achieving the same level of precision as CNC machining, especially for large – scale parts. For instance, in FDM 3D printing, the layer – by – layer deposition process can result in a visible stair – step effect on curved surfaces, which may affect the overall accuracy and surface finish of the part. Additionally, factors such as material shrinkage during the curing or cooling process in additive manufacturing can also introduce dimensional inaccuracies.

3.2 Material Options

CNC machining offers a vast range of material options. It can work with a wide variety of metals, including aluminum, steel, titanium, and copper. These metals are widely used in industries such as automotive and aerospace due to their high strength – to – weight ratios and excellent mechanical properties. For example, in the automotive industry, CNC – machined aluminum parts are used in engine blocks and chassis components to reduce weight and improve fuel efficiency. CNC machining can also process various plastics, such as ABS, PVC, and PEEK, which are commonly used in consumer products, electronics, and medical equipment. Moreover, it can handle natural materials like wood and composites, expanding its application scope.

While additive manufacturing materials are constantly evolving, the range of available materials is still more limited compared to CNC machining. In polymer – based additive manufacturing, materials like PLA, ABS, and PETG are commonly used. These materials are suitable for creating prototypes, small – scale production parts, and consumer – facing products. However, their mechanical properties may not be as robust as those of metals in some cases. Metal additive manufacturing has made significant progress, with materials such as titanium, aluminum, and stainless steel being available. But the cost of these metal powders and the specialized equipment required for metal additive manufacturing can be relatively high. For example, in the aerospace industry, the use of metal additive manufacturing for critical components is still restricted in some cases due to concerns about material properties and cost – effectiveness.

3.3 Complexity of Shapes

Manufacturing complex shapes with CNC machining can be challenging and often requires multiple machining operations and the use of specialized cutting tools. For example, creating a part with internal cavities, undercuts, or complex curved surfaces may involve milling, drilling, and turning operations, which need careful planning and programming. Each operation must be precisely executed to ensure that the final part meets the design requirements. In some cases, additional fixtures and tooling may be necessary to hold the workpiece in place during machining, further increasing the complexity and cost of the process.

Additive manufacturing, on the other hand, excels at producing complex geometries. It can create parts with intricate internal structures, such as lattice – like frameworks for lightweighting or internal channels for fluid flow, which are extremely difficult or even impossible to achieve with traditional CNC machining. For example, in the design of heat – exchangers, additive manufacturing can be used to create complex internal channel structures that maximize heat transfer efficiency while minimizing weight. The ability to build parts layer by layer allows for the creation of parts with free – form surfaces and unique shapes without the need for complex tooling or multiple set – ups. This design freedom has opened up new possibilities for product innovation in various industries.

3.4 Production Efficiency

CNC machining is highly efficient for high – volume production. Once the CNC program is set up and the machine is calibrated, it can produce parts with high repeatability at a relatively fast rate. For example, in the automotive industry, CNC – machined parts are produced in large quantities to meet the demands of mass production. The use of automated loading and unloading systems can further increase the production efficiency, allowing the machine to run continuously for long periods. However, the set – up time for CNC machining can be relatively long, especially for complex parts that require multiple operations and tool changes. This set – up time includes tasks such as programming the CNC machine, selecting and installing the appropriate cutting tools, and positioning the workpiece accurately.

Additive manufacturing, on the contrary, shines in small – batch production and customized manufacturing. It can quickly produce one – off or small – quantity parts without the need for expensive tooling or long set – up times. For example, in the dental industry, additive manufacturing is used to produce customized dental crowns and implants. Each crown or implant is designed specifically for an individual patient based on their unique dental structure, and additive manufacturing can rapidly produce these customized parts. In addition, additive manufacturing can integrate multiple components into a single part, reducing the need for assembly and potentially saving production time. However, for large – scale production, the layer – by – layer manufacturing process of additive manufacturing can be time – consuming, and the production speed may not be able to match that of CNC machining.

3.5 Cost Considerations

The cost of CNC machining is influenced by several factors. The initial investment in CNC machinery can be substantial, especially for high – end multi – axis machines. For example, a five – axis CNC machining center can cost hundreds of thousands of dollars. The cost of materials is also a significant factor, as CNC machining often requires large blocks of raw material, and the material waste during the subtractive process can increase the overall cost. Labor costs are another consideration, as skilled operators and programmers are needed to operate and program the CNC machines. Additionally, the cost of tooling, such as cutting tools and fixtures, can add up, especially for complex machining operations. However, in high – volume production, the unit cost of parts can be reduced due to the high production efficiency and the ability to amortize the fixed costs over a large number of parts.

Additive manufacturing has its own cost – related aspects. The equipment cost for additive manufacturing can vary widely. Desktop 3D printers for hobbyist or small – scale use can be relatively inexpensive, costing a few hundred to a few thousand dollars. However, industrial – grade additive manufacturing equipment, especially those for metal 3D printing, can be extremely costly, often in the hundreds of thousands or even millions of dollars. Material costs in additive manufacturing can also be high, particularly for specialized materials like high – performance polymers or metal powders. On the positive side, additive manufacturing generally has lower tooling costs, as it doesn’t require the creation of complex molds or fixtures like traditional manufacturing methods. In small – batch or customized production, additive manufacturing can be cost – effective as it eliminates the need for expensive tooling and setup for each new part design. But for large – scale production, the high cost of materials and the relatively slow production speed may make it less cost – competitive compared to CNC machining.

4. Applications in Different Industries

4.1 Aerospace Industry

In the aerospace industry, both CNC machining and additive manufacturing play crucial and complementary roles.

CNC machining is extensively used for manufacturing high – precision structural components. For example, in the production of aircraft fuselage frames, CNC – machined aluminum alloy parts are essential. These parts require tight tolerances to ensure a perfect fit during the assembly process. The high – speed and high – precision milling capabilities of CNC machines can create complex shapes and smooth surfaces on the aluminum alloy blocks, which are then assembled to form the fuselage frame. This ensures the structural integrity and aerodynamic performance of the aircraft. Another example is the manufacturing of wing spars. These long, slender components need to have consistent cross – sectional dimensions and high – quality surface finishes. CNC machining can meet these requirements by precisely removing material from large billets of high – strength metals, such as titanium alloys, which are known for their excellent strength – to – weight ratios and high – temperature resistance.

Additive manufacturing, on the other hand, is revolutionizing the production of complex and lightweight components in the aerospace industry. One of the most prominent examples is the use of metal 3D printing to create engine components. For instance, the combustion chambers of rocket engines often have complex internal geometries, including cooling channels and intricate fuel – injection systems. These components are extremely difficult to manufacture using traditional methods. With additive manufacturing, specifically selective laser melting (SLM) or electron beam melting (EBM), it is possible to build these combustion chambers layer by layer, directly from a digital model. This not only enables the creation of complex geometries but also significantly reduces the weight of the components, which is crucial for improving the fuel efficiency and performance of rockets. In addition, additive manufacturing is also used for producing lightweight lattice – structured brackets and connectors. These lattice structures can provide the necessary strength while minimizing the weight, making them ideal for use in aerospace applications where every ounce of weight reduction matters.

4.2 Automotive Industry

The automotive industry is another sector where CNC machining and additive manufacturing have found wide – spread applications.

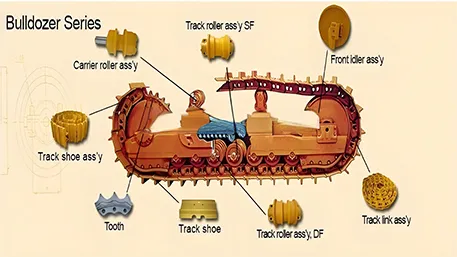

CNC machining is the backbone of producing many critical automotive components. Engine parts, such as cylinder heads, engine blocks, and crankshafts, are typically manufactured using CNC machining. Cylinder heads, for example, require precise machining of combustion chambers, valve seats, and coolant passages. CNC machining centers can accurately mill, drill, and bore these complex features in the cast aluminum or cast iron blanks, ensuring the proper functioning of the engine. Engine blocks, which house the cylinders, pistons, and other moving parts, also need to be machined to extremely tight tolerances. The high – precision capabilities of CNC machines can create the smooth cylinder walls and flat mating surfaces required for optimal engine performance. Crankshafts, which convert the reciprocating motion of the pistons into rotational motion, are also CNC – machined from high – strength steel. The complex shape of the crankshaft, with its multiple journals and counterweights, demands the use of advanced CNC turning and milling operations to achieve the required surface finish and dimensional accuracy.

Transmission components, such as gears, shafts, and transmission housings, are also commonly produced by CNC machining. Gears, which are responsible for transferring power and changing the speed ratio in the transmission, need to have precise tooth profiles and accurate spacing. CNC gear – hobbing machines and CNC milling machines can manufacture these gears with high precision, ensuring smooth operation and minimal noise. Shafts, which connect the gears and transfer torque, are also machined to tight tolerances to ensure proper alignment and rotation. Transmission housings, which enclose the gears and other components, are typically made of aluminum alloy and are CNC – machined to create the precise cavities and mounting surfaces required for the assembly of the transmission.

Additive manufacturing is increasingly being used in the automotive industry, especially for rapid prototyping and customized production. In the design and development phase, automotive manufacturers use 3D printing to quickly create prototypes of new parts or components. This allows designers to test and validate their designs before investing in expensive tooling and mass production. For example, a new concept for a car interior component, such as a dashboard or a center console, can be 3D – printed in a short period. This prototype can then be evaluated for fit, form, and function, and any necessary design changes can be made quickly. In addition, additive manufacturing is also used for producing customized parts for high – end or specialty vehicles. For instance, luxury car manufacturers may use 3D printing to create unique interior trim pieces or exterior body panels for limited – edition models. These customized parts can be designed to meet the specific requirements of individual customers, adding a touch of exclusivity to the vehicles. Moreover, additive manufacturing is also being explored for the production of lightweight components in electric vehicles. By using 3D – printed lattice – structured parts, automakers can reduce the weight of the vehicle, which in turn improves the battery range and overall performance.

4.3 Medical Field

In the medical field, both CNC machining and additive manufacturing have made significant contributions to improving patient care and medical device development.

CNC machining is widely used for manufacturing surgical instruments. For example, scalpels, forceps, and surgical drills are often made from high – quality stainless steel or titanium alloys using CNC machining. These instruments require precise cutting edges, smooth surfaces, and ergonomic designs. CNC machining can achieve the high – precision machining required to create these features. Scalpels, which are used for making incisions during surgeries, need to have extremely sharp cutting edges. CNC – controlled grinding and polishing processes can ensure that the scalpel blades are sharp and free from any defects. Forceps, which are used for grasping and manipulating tissues, need to have precise jaw alignments and smooth operating mechanisms. CNC machining can manufacture the forceps’ components with tight tolerances, ensuring smooth and reliable operation. Surgical drills, which are used for drilling holes in bones during orthopedic surgeries, require accurate and consistent drilling diameters. CNC – machined drill bits can meet these requirements, providing surgeons with the precision they need to perform surgeries safely and effectively.

Additive manufacturing has revolutionized the production of customized implants, prosthetics, and medical models in the medical field. Customized implants, such as hip replacements and dental implants, can be designed and manufactured using additive manufacturing techniques. For hip replacements, a patient’s hip joint can be scanned using 3D imaging technology, such as CT or MRI. The scan data is then used to create a 3D model of the patient’s hip, which is customized to fit the patient’s unique anatomy. Using metal 3D printing, such as selective laser melting, a hip implant can be fabricated that closely matches the patient’s bone structure. This customized implant can provide better fit, improved stability, and reduced risk of implant failure compared to traditional off – the – shelf implants. In the case of dental implants, additive manufacturing can be used to create implants with complex internal structures that promote better osseointegration, the process by which the implant fuses with the surrounding bone.

Prosthetics are also being transformed by additive manufacturing. Custom – made prosthetics can be designed to fit the specific needs and body contours of individual amputees. A 3D scan of the amputee’s residual limb is taken, and a prosthetic socket is designed and 3D – printed to provide a comfortable and secure fit. The use of additive manufacturing allows for the creation of lightweight and durable prosthetics with complex geometries, such as flexible joints and internal lattice structures. These features can improve the functionality and comfort of the prosthetics, enabling amputees to have a better quality of life.

Medical models are another important application of additive manufacturing in the medical field. Surgeons can use 3D – printed models of patient’s organs or anatomical structures to plan complex surgeries. For example, a 3D – printed model of a patient’s heart can be used to study the location and extent of a heart defect before performing heart surgery. This allows surgeons to develop a more accurate surgical plan, practice the surgical procedure, and reduce the risk of complications during the actual surgery. In addition, medical models can also be used for medical education and training, providing students and trainees with a hands – on learning experience.

5. Future Trends and Developments

5.3 Market and Industry Impact

The development of CNC machining and additive manufacturing is bound to have a profound impact on the manufacturing market structure, supply chain models, and enterprise competitiveness.

Market Structure

CNC Machining: In the long – term, CNC machining will continue to dominate in high – volume production scenarios. As the technology evolves towards higher precision, speed, and multi – axis capabilities, it will further strengthen its position in industries with large – scale production demands, such as the automotive and consumer electronics industries. For example, in the automotive industry, where millions of parts are produced annually, CNC machining’s high – volume production efficiency and consistent quality will keep it as the primary manufacturing method for many components. However, with the rise of additive manufacturing, CNC machining may face some competition in the production of complex – shaped parts that were previously difficult to manufacture. This could lead to a shift in the market share within the manufacturing industry, with CNC machining focusing more on its traditional strongholds of high – volume, high – precision production.

Additive Manufacturing: Additive manufacturing is likely to disrupt the traditional market structure by enabling new business models. The ability to produce customized products on – demand can open up new market segments, especially in the fields of personalized healthcare products, luxury goods, and small – batch, high – value – added products. For instance, in the jewelry industry, additive manufacturing allows for the creation of unique, one – of – a – kind pieces, which can attract high – end consumers. As the technology becomes more accessible and cost – effective, it may also lead to the emergence of more small – scale, decentralized manufacturing enterprises, challenging the dominance of large – scale, traditional manufacturing plants.

Supply Chain Models

CNC Machining: The supply chain for CNC machining is relatively traditional, with a focus on large – scale raw material procurement, long – lead – time tooling production, and centralized manufacturing facilities. However, with the development of Industry 4.0 and the Internet of Things (IoT), there is a trend towards more intelligent supply chains. CNC machining centers can now be connected to a network, allowing for real – time monitoring of inventory levels, production progress, and equipment status. This enables more efficient supply chain management, reducing inventory costs and improving production planning. For example, a CNC machining factory can use IoT – enabled sensors to monitor the wear and tear of cutting tools. When a tool is approaching the end of its lifespan, the system can automatically order a replacement, ensuring uninterrupted production.

Additive Manufacturing: Additive manufacturing has the potential to revolutionize the supply chain model. It can enable distributed manufacturing, where products can be produced closer to the end – user. This reduces the need for long – distance transportation of finished products, shortening lead times and reducing logistics costs. For example, spare parts for industrial equipment can be 3D – printed on – site or in a nearby facility when needed, rather than being stored in large warehouses and shipped from a central location. In addition, the digital nature of additive manufacturing means that product designs can be easily shared and modified, enabling rapid response to changing market demands. This could lead to a more agile and responsive supply chain, with less reliance on large – scale inventory and complex distribution networks.

Enterprise Competitiveness

CNC Machining: For enterprises that rely on CNC machining, competitiveness will increasingly depend on their ability to invest in advanced CNC equipment, train highly skilled operators, and optimize production processes. Those that can adopt new technologies, such as multi – axis machining, high – speed machining, and automation, will be able to produce higher – quality products at a lower cost, gaining a competitive edge in the market. For example, a CNC machining company that invests in a state – of – the – art five – axis machining center can take on more complex and high – value projects, attracting customers who require precision – engineered components. Moreover, companies that can integrate CNC machining with other manufacturing processes, such as 3D printing in a hybrid manufacturing setup, will be able to offer more comprehensive solutions to their customers.

Additive Manufacturing: In the context of additive manufacturing, enterprise competitiveness will be centered around technological innovation, material development, and design expertise. Companies that can develop new and improved additive manufacturing technologies, such as faster printing speeds, higher precision, and better material properties, will be at the forefront of the market. For example, a company that invents a new metal 3D printing process with superior strength and durability for aerospace applications will have a significant competitive advantage. Additionally, those with strong design capabilities can leverage the design freedom of additive manufacturing to create innovative products that are difficult to produce with traditional methods. This could lead to the creation of unique selling points, allowing enterprises to charge premium prices for their products.

Conclusion

In conclusion, CNC machining and additive manufacturing are two powerful forces in the modern manufacturing landscape, each with its own set of characteristics, advantages, and application scenarios.

CNC machining, with its long – standing history and well – established processes, excels in producing high – precision parts with tight tolerances. It offers a wide range of material options, making it suitable for a diverse array of industries. Its high – volume production efficiency and consistent quality make it the go – to choice for mass – production scenarios. However, it may face challenges when dealing with complex geometries, and the initial setup costs can be relatively high.

Additive manufacturing, on the other hand, represents a revolutionary approach to manufacturing. It has the unique ability to create complex shapes and customized products with ease, opening up new possibilities for product design and innovation. It is highly efficient for small – batch production and rapid prototyping, reducing lead times and costs in these scenarios. Although the range of available materials is still somewhat limited compared to CNC machining, and the precision may not always match that of CNC in all cases, continuous technological advancements are rapidly narrowing these gaps.

In the future, the manufacturing industry is likely to see an even greater integration of these two technologies. Hybrid manufacturing systems that combine the strengths of CNC machining and additive manufacturing are already emerging, allowing for the production of parts that leverage the best of both worlds. As technology continues to evolve, we can expect to see further improvements in the precision, speed, and material capabilities of both CNC machining and additive manufacturing. This will not only lead to more efficient and cost – effective manufacturing processes but also drive innovation across various industries, from aerospace and automotive to healthcare and consumer goods. The key for manufacturers will be to carefully evaluate their specific needs and choose the most appropriate manufacturing technology or combination of technologies to achieve their production goals.