Table of Contents

- Overall Equipment Structure Design

- Spindle System Core Technology

- Feed Drive System

- Tool Magazine and Automatic Tool Changer

- Control System and Programming Technology

- Precision Control and Measurement

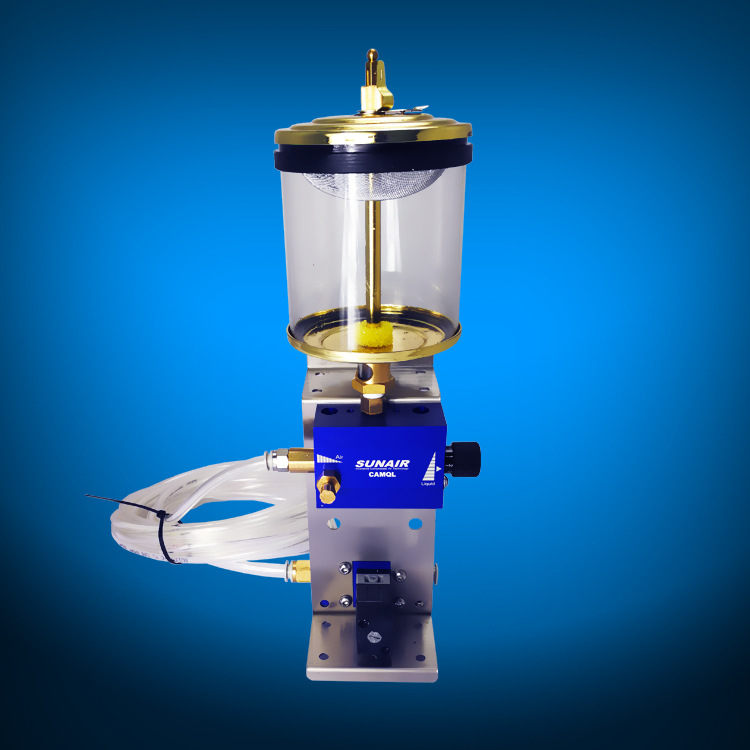

- Cooling and Lubrication System

- Safety Protection Design

- Maintenance and Service Technology

- Application Fields and Technical Advantages

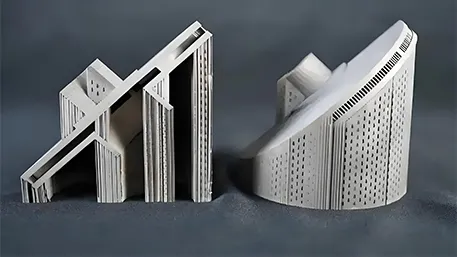

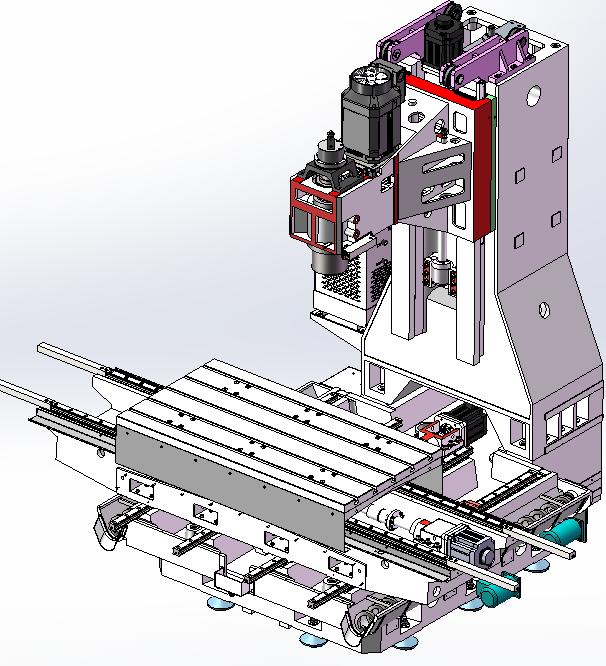

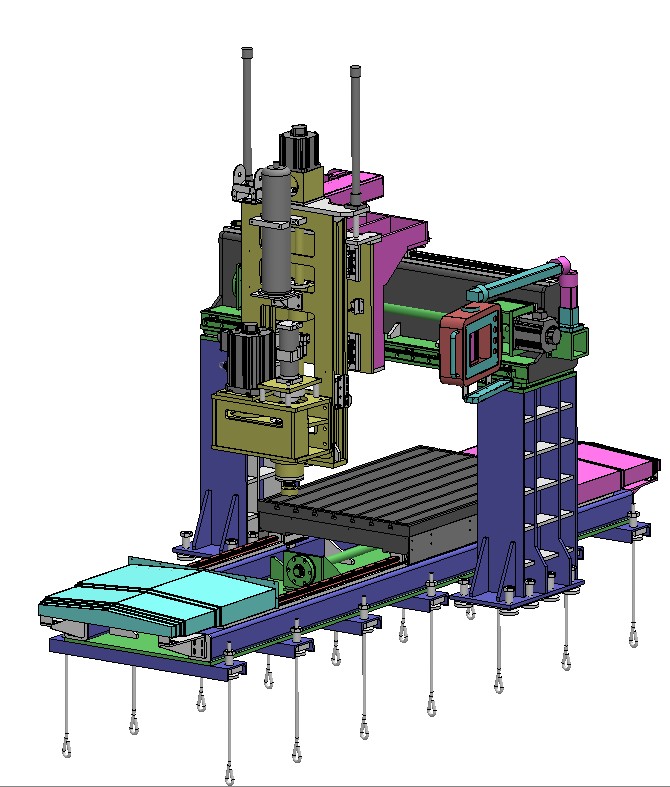

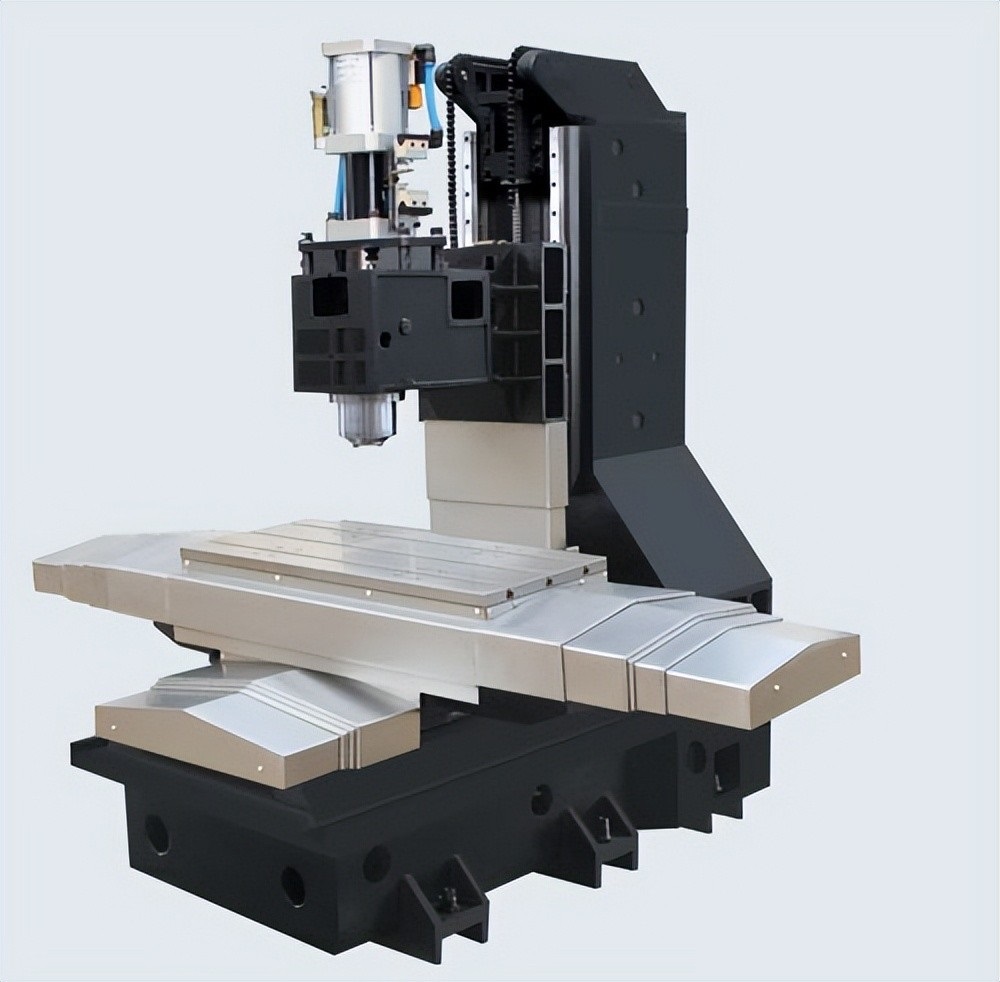

Overall Equipment Structure Design

- Machine Base – Provides stable foundation support, constructed from high-strength cast iron or granite materials

- Column – Supports the spindle head, requiring excellent rigidity and vibration resistance

- Spindle Head – Houses the spindle assembly, enabling rotational movement of the spindle

- Worktable – Carries the workpiece, achieve ing X, Y, Z axis feed movements

- Tool Magazine – Stores and manages cutting tools, supporting automatic tool changing functionality

- Control System – Implements digital control of the machining process

- Rigid Design – Optimized using finite element analysis to ensure machining stability

- Thermal Symmetric Design – Reduces the impact of temperature changes on precision

- Modular Design – Facilitates maintenance and functional expansion

- Ergonomic Design – Optimized operator interface and maintenance access

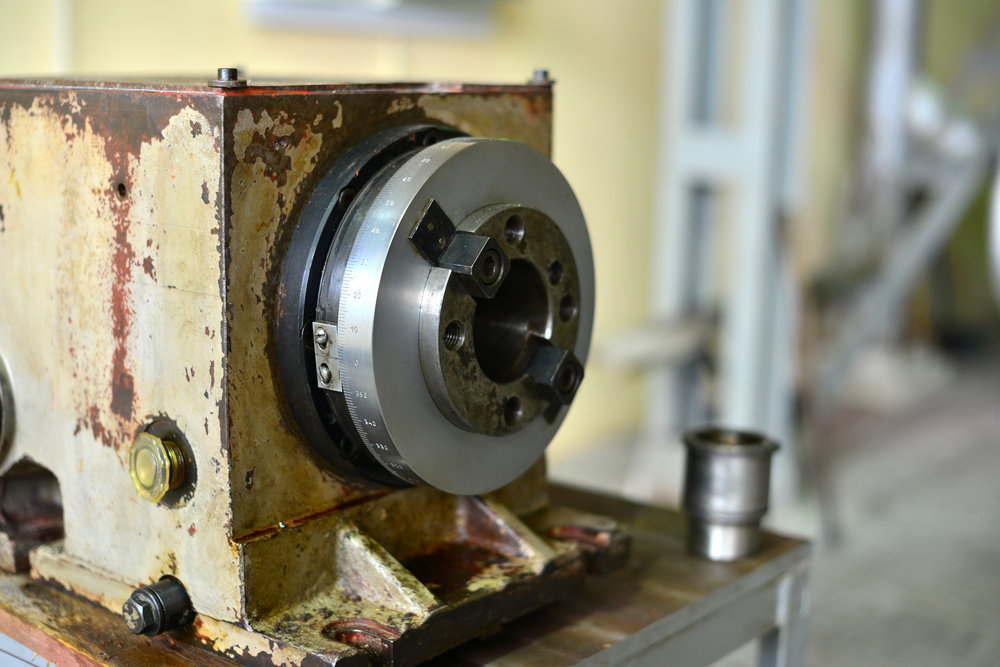

Spindle System Core Technology

|

Parameter Item

|

Technical Specification

|

Technical Features

|

|

Spindle Speed

|

8000-15000 RPM

|

Variable frequency control, constant power output

|

|

Spindle Taper

|

BT40/BT50

|

High-precision taper 配合

|

|

Spindle Motor Power

|

7.5-22 kW

|

Direct servo motor drive

|

|

Axial/Radial Runout

|

≤0.003mm

|

High-precision bearing support

|

- High-Precision Bearings – Utilizing ceramic bearings or precision angular contact ball bearings

- Oil Mist Lubrication – Ensuring proper lubrication and cooling of bearings at high speeds

- Spindle Temperature Control – Active temperature control system maintains stable spindle temperature

- Dynamic Balancing Technology – Reduces vibration during high-speed rotation

- Belt Drive – Suitable for medium-low speed spindles, cost-effective

- Direct Drive – Motor directly drives the spindle, high transmission precision

- Motorized Spindle – Motor rotor integrated with spindle, speeds up to 40000 RPM

Feed Drive System

- Servo Motor – Provides power output, utilizing AC servo motors

- Ball Screw – Converts rotational motion to linear motion

- Guideway System – Ensures motion precision and stability

- Position Detection – Real-time position feedback

- High-Precision Ball Screws – Pitch error compensation, positioning accuracy up to ±0.005mm

- Linear Guideways – Low friction coefficient, smooth motion

- Servo Control System – Achieves precise control of position, speed, and torque

- Dynamic Error Compensation – Real-time compensation of motion errors

|

Axis

|

Rapid Traverse Speed

|

Feed Rate

|

Positioning Accuracy

|

|

X-axis

|

30-48 m/min

|

1-24 m/min

|

±0.003mm

|

|

Y-axis

|

30-48 m/min

|

1-24 m/min

|

±0.003mm

|

|

Z-axis

|

24-36 m/min

|

1-18 m/min

|

±0.003mm

|

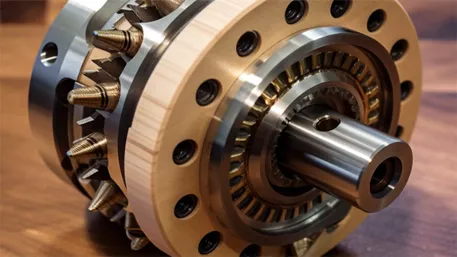

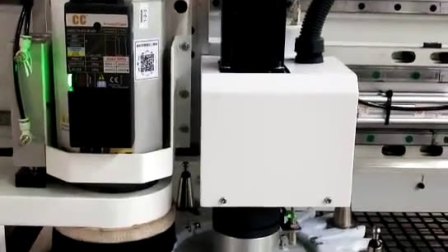

Tool Magazine and Automatic Tool Changer

1. Turret-Type Tool Magazine

- Capacity: 16-24 tools

- Tool Change Time: 8-12 seconds

- Structural Features: Simple structure, cost-effective

- Application: Small to medium batch production

2. Disc-Type Tool Magazine

- Capacity: 20-40 tools

- Tool Change Time: 6-8 seconds

- Structural Features: Compact footprint, fast tool change

- Application: Medium batch production

3. Chain-Type Tool Magazine

- Capacity: 40-120 tools

- Tool Change Time: 12-15 seconds

- Structural Features: Large capacity, expandable

- Application: Large batch complex part machining

- Robot Arm Tool Change – Cam or hydraulic driven, precise movement

- Tool Position Detection – Photoelectric sensors confirm tool position

- Tool Identification – RFID or encoder disc for tool information

- Automatic Tool Length Compensation – Tool length measurement and compensation

- Tool Life Management – Monitors tool usage time and cutting cycles

- Tool Breakage Detection – Real-time tool condition monitoring

- Tool Presetting – Offline tool parameter setting

- Tool Change Optimization – Optimizes tool change sequence to reduce time

Control System and Programming Technology

1. Fanuc Series 0i-MF

- Control Axes: Up to 6-axis simultaneous control

- Program Storage: 32MB memory, expandable to 2GB

- Special Features: AI contour control, high-speed high-precision machining

- User Interface: Color LCD display, user-friendly operation

2. Siemens SINUMERIK 828D

- Control Axes: Up to 5-axis simultaneous control

- Programming Method: ShopMill/ShopTurn conversational programming

- Special Features: 3D simulation, collision detection

- Network Functionality: Industrial Ethernet support

3. Mitsubishi M80

- Control Axes: Up to 8-axis simultaneous control

- Processing Speed: 32-bit RISC processor

- Special Features: High-speed look-ahead control

- Communication Interfaces: USB, Ethernet, RS232

- G-code Programming – Standard CNC programming language

- M-code Programming – Auxiliary function control

- Macro Programming – Custom cycle programs

- CAD/CAM Integration – Computer-aided programming

- High-Speed Look-Ahead – Preprocessing of machining paths

- Adaptive Control – Adjusts feed rate based on cutting load

- Error Compensation – Geometric error and thermal error compensation

- Remote Monitoring – Real-time equipment status monitoring

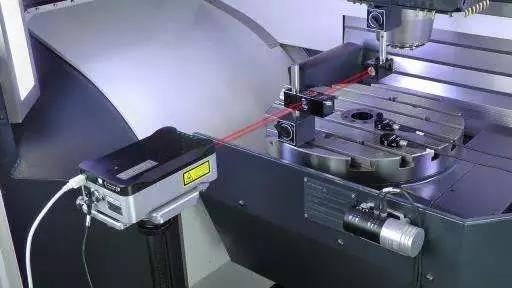

Precision Control and Measurement

1. Geometric Precision

- Positioning Accuracy: ±0.003-±0.005mm

- Repeatability: ±0.002-±0.003mm

- Straightness: 0.002mm/m

- Perpendicularity: 0.002mm/m

2. Motion Precision

- Circular Interpolation Accuracy: ±0.003mm

- Thread Machining Accuracy: ISO 4H/5g

- Surface Roughness: Ra 0.8-3.2μm

3. Machining Precision

- Dimensional Accuracy: IT5-IT7 grade

- Geometric Tolerances: 0.005-0.01mm

- Surface Quality: Mirror finish achievable

- Laser Interferometer – Measures positioning accuracy and geometric errors

- Ballbar Testing – Evaluates dynamic accuracy and servo performance

- Coordinate Measuring Machine (CMM) – Verifies final workpiece accuracy

- In-Process Measurement – Real-time precision monitoring during machining

- Temperature Control – Workshop temperature maintained at 20±2°C

- Vibration Isolation – Anti-vibration foundations and damping measures

- Error Compensation – Geometric, thermal, and load error compensation

- Regular Calibration – Precision calibration according to standards

Cooling and Lubrication System

1. Cutting Fluid Cooling System

- Function: Cools tools and workpiece, flushes away chips

- Types: Emulsions, synthetic coolants, oil-based cutting fluids

- Circulation Method: Pump circulation, filtration precision 20-50μm

- Cooling Capacity: 5-20kW cooling capacity

2. Spindle Cooling System

- Cooling Method: Oil or water cooling

- Temperature Control Precision: ±1°C

- Flow Control: Automatic adjustment based on spindle load

- Heat Dissipation Capacity: Matches spindle power requirements

3. Machine Cooling System

- Cooling Objects: Electrical cabinet, servo motors, ball screws

- Cooling Method: Air or liquid cooling

- Temperature Control: Maintains stable operating temperature

- Energy-Saving Design: Intelligent temperature control, on-demand cooling

- Lubrication Methods: Oil-air lubrication, grease lubrication

- Lubrication Points: Ball screws, guideways, spindle bearings

- Lubrication Cycle: Programmable automatic lubrication

- Condition Monitoring: Real-time monitoring of lubrication system status

- Intelligent Control – Automatic adjustment based on machining conditions

- Energy Efficiency – Optimized cooling and lubrication parameters, reduced energy consumption

- Maintenance-Friendly – Modular design for easy maintenance

- Environmental Compliance – Meets environmental protection standards

Safety Protection Design

1. Mechanical Protection

- Safety Doors – Interlock protection, machine stops when door opens

- Protective Covers – Prevent chip and coolant splashing

- Emergency Stop Buttons – Rapid machine shutdown in emergency situations

- Safety Locks – Prevent unauthorized operation

2. Electrical Safety

- Overload Protection – Motor overload and short circuit protection

- Earth Leakage Protection – Protection against electrical equipment leakage

- Overvoltage Protection – Voltage anomaly protection

- EMC Protection – Electromagnetic compatibility protection

3. Control System Safety

- Program Protection – Machining program password protection

- Operation Permissions – Multi-level user permission management

- Error Detection – Program error and operation error detection

- Emergency Stop – Multiple emergency stop circuits

- ISO 13849 – Machinery safety standard

- IEC 61508 – Functional safety standard

- CE Certification – European safety certification

- OSHA Standards – American occupational safety standards

- Area Monitoring – Hazardous area intrusion detection

- Status Display – Real-time display of equipment operating status

- Alarm System – Fault and abnormal condition alarms

- Log Recording – Safety event and operation logging

Maintenance and Service Technology

1. Daily Maintenance

- Cleaning – Equipment exterior and work area cleaning

- Lubrication Check – Lubrication system oil level and quality inspection

- Cooling System – Coolant level and concentration check

- Air Pressure System – Air pressure and leakage inspection

2. Periodic Maintenance

- Guideway and ball screw cleaning and lubrication

- Filter inspection and cleaning

- Electrical cabinet cooling inspection

- Safety device function check

- Spindle system condition inspection

- Servo motor temperature check

- Hydraulic system pressure inspection

- Tool clamping system check

- Precision measurement and calibration

- Transmission system backlash inspection

- Electrical system insulation test

- Software backup and updates

3. Annual Maintenance

- Comprehensive precision measurement and adjustment

- Spindle bearing condition assessment

- Servo system performance testing

- Control system function check

|

Maintenance Interval

|

Maintenance Item

|

Maintenance Content

|

Responsible Person

|

|

Daily

|

Routine Inspection

|

Cleaning, lubrication, level checks

|

Operator

|

|

Weekly

|

Regular Inspection

|

Guideway lubrication, filter cleaning

|

Technician

|

|

Monthly

|

In-depth Inspection

|

Spindle inspection, hydraulic system

|

Engineer

|

|

Annual

|

Comprehensive Maintenance

|

Precision calibration, system testing

|

Professional Service

|

- Fault Codes – System fault code analysis

- Condition Monitoring – Equipment operating status monitoring

- Diagnostic Tools – Specialized diagnostic software and tools

- Spare Parts Management – Critical spare parts inventory management

Application Fields and Technical Advantages

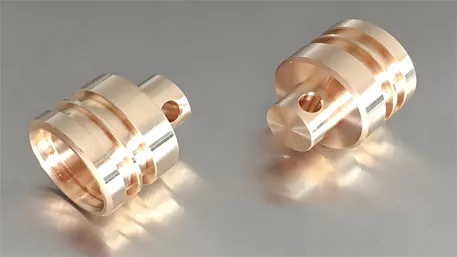

1. Aerospace Manufacturing

- Application Components: Engine parts, structural components, landing gear parts

- Technical Requirements: High precision, high reliability, complex shapes

- Material Processing: Titanium alloys, aluminum alloys, high-temperature alloys

- Quality Standards: AS9100 certification, strict quality control

2. Automotive Manufacturing

- Application Components: Engine blocks, transmission parts, chassis components

- Technical Requirements: High volume, high efficiency, good consistency

- Production Features: High automation, flexible manufacturing

- Quality Standards: IATF16949 certification

3. Medical Device Manufacturing

- Application Components: Surgical instruments, implants, medical equipment parts

- Technical Requirements: Ultra-high precision, excellent surface quality, biocompatibility

- Material Requirements: Titanium alloys, stainless steel, ceramic materials

- Quality Standards: ISO13485 certification

4. Mold Manufacturing

- Application Components: Plastic molds, stamping dies, die casting molds

- Technical Requirements: Complex surface machining, high precision, surface quality

- Processing Features: Single-piece small batch, high customization

- Technical Challenges: Deep cavity machining, micro-machining

- High-Precision Machining – Positioning accuracy up to ±0.003mm

- High-Efficiency Production – Automatic tool change, reduced auxiliary time

- Flexible Manufacturing – Rapid changeover, adaptable to multiple product types

- Complex Shape Machining – Multi-axis simultaneous machining of complex surfaces

- High Automation Level – Enables unmanned production

- Stable Quality – Consistent machining quality and reliability

- Production Efficiency – 3-5 times improvement compared to traditional machines

- Labor Costs – Reduced labor requirements, lower labor costs

- Quality Costs – Reduced scrap rates, lower quality costs

- Return on Investment – Typically 2-3 year payback period

Summary and Future Outlook

- Higher Precision – Positioning accuracy moving toward nanometer level

- Higher Speed – Continued increase in spindle speeds and feed rates

- Intelligentization – Integration of AI technology for adaptive machining

- Green Technology – Continuous improvement of energy-saving and environmental protection technologies

- Integration – Deep integration with CAD/CAM systems

- Networking – Implementation of factory network management

- 5-Axis Machining Technology – Complex parts completed in single setup

- Additive Manufacturing Integration – Combination of CNC machining with 3D printing technology

- Digital Twin Technology – Synchronization of virtual simulation with actual machining

- Industry 4.0 Integration – Core component of smart factories

- ISO 230-1:2012 – Test code for machine tools

- ISO 10791-1:2014 – CNC milling machines

- GB/T 18400.1-2010 – Machine tools safety standards

- DIN 8603 – Accuracy of machine tools