Introduction

In today’s fast-paced manufacturing world, CNC machining customized services have become the backbone of innovation for businesses looking to create parts that perfectly fit their unique needs. Unlike off-the-shelf components that force you to compromise on design or performance, custom CNC machining lets you create exactly what you need, when you need it.

This guide is designed to walk you through everything you need to know about custom CNC machining services. Whether you’re an engineer working on a new product design, a procurement manager sourcing components, or a business owner looking to manufacture custom parts, we’ve got you covered.

What Exactly Are CNC Machining Customized Services?

Breaking It Down Simply

CNC machining customized services are all about creating tailor-made parts using computer-controlled machines. Instead of buying standard parts that might not be perfect for your application, you work with a manufacturer to design and produce components that meet your exact specifications.

Think of it like ordering a custom suit versus buying one off the rack. The custom option might take a bit longer and cost a bit more, but the fit and quality are worth it for critical applications.

What Makes Custom CNC Machining Special?

- Perfect Fit: Parts are made to your exact measurements

- Design Freedom: Create complex shapes that standard manufacturing can’t handle

- Material Choice: Select the exact material for your application

- Quality Control: Every part meets your specific quality standards

- Flexibility: From one prototype to thousands of production parts

Why Choose Custom CNC Machining Services?

Unleash Your Design Creativity

With custom CNC machining, you’re not limited by what’s available in catalogs. Want to create a part with complex internal channels? No problem. Need a component with very tight tolerances? We can handle that. The only limit is your imagination (and the laws of physics, of course).

Get Exactly What You Need

One of the biggest advantages of custom machining is precision. When you work with a reputable CNC shop, you can expect parts that match your CAD drawings exactly. This means fewer assembly issues, better performance, and higher quality end products.

Save Time and Money in the Long Run

While custom parts might cost more upfront than standard components, they often save you money in the long run. You won’t have to modify standard parts to fit your application, and you’ll reduce waste from ill-fitting components. Plus, with modern CNC technology, lead times are shorter than ever.

Stay Competitive in Your Industry

In today’s competitive marketplace, having unique, high-quality components can give you a significant edge over your competitors. Custom CNC machining lets you create products that stand out from the crowd and meet the specific needs of your customers.

The Custom CNC Machining Process Explained

Step 1: Let’s Talk About Your Project

The process starts with a conversation. You’ll discuss your project requirements with the CNC shop’s engineers. This is where you’ll share your CAD files, talk about materials, and discuss any special requirements or challenges.

A good CNC shop will ask lots of questions to make sure they fully understand your needs. They might even suggest design improvements to make the part easier to manufacture or more cost-effective.

Step 2: Design and Engineering Support

Once the initial consultation is complete, the engineering team will review your design. They’ll check for manufacturability issues and make suggestions to optimize the design for CNC machining.

This is where Design for Manufacturability (DFM) comes into play. By making small changes to your design, you can often reduce costs and improve quality without compromising on performance.

Step 3: Prototyping – Let’s Test It Out

Before committing to full production, most shops will create a prototype. This lets you test the part’s fit and function before investing in tooling and production.

Prototyping is especially important for complex parts or new designs. It gives you a chance to make adjustments early in the process when changes are still relatively inexpensive.

Step 4: Production Planning

Once the prototype is approved, it’s time to plan for production. The shop will determine the best machines and processes for your part, select the appropriate tools, and create a production schedule.

This is also when you’ll get a final quote for the production run. Be sure to ask about volume discounts if you need a large number of parts.

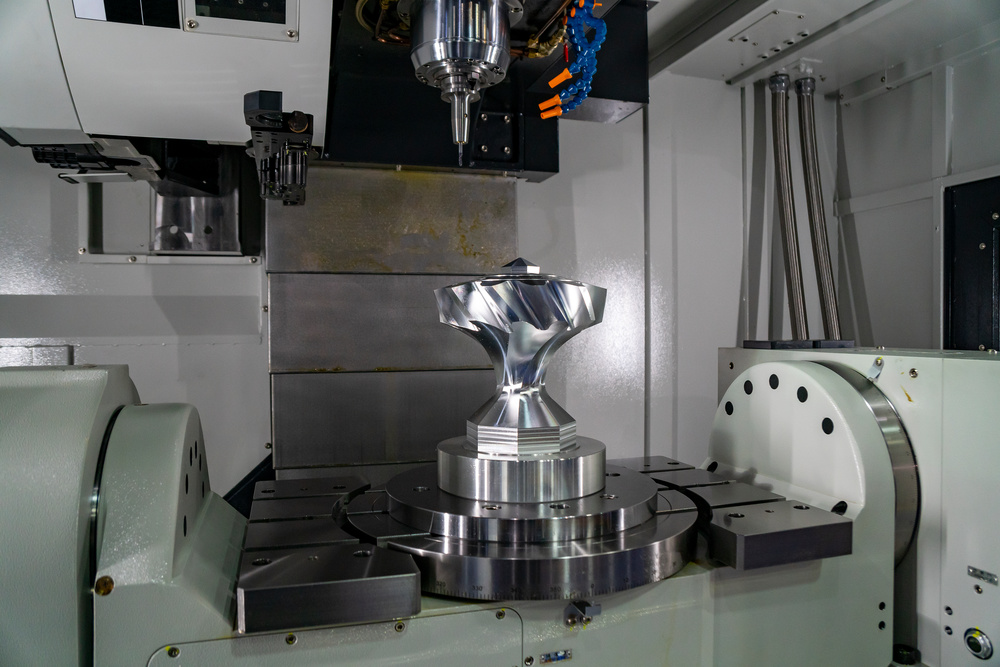

Step 5: Let’s Make Some Parts

With the planning complete, production can begin. The CNC machines will run your part program, and skilled operators will monitor the process to ensure quality.

Most shops perform in-process inspections to catch any issues early. This helps ensure that every part meets your specifications.

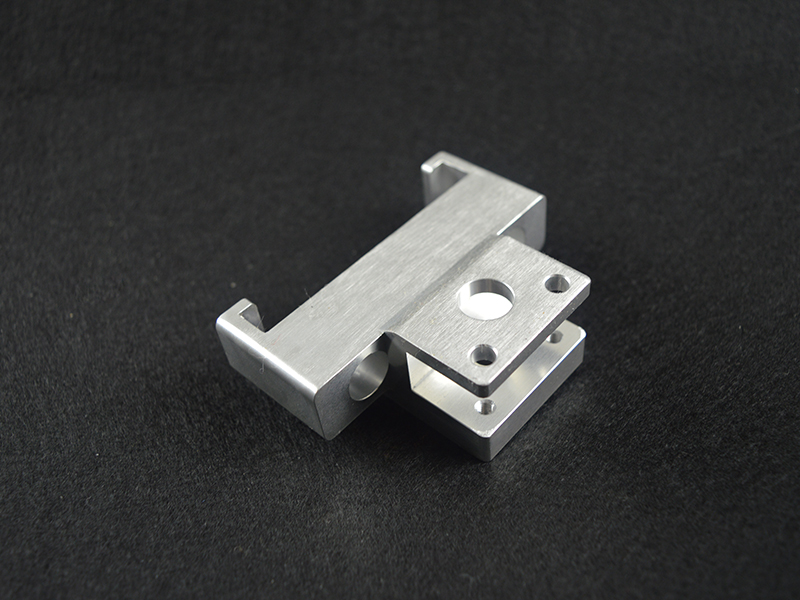

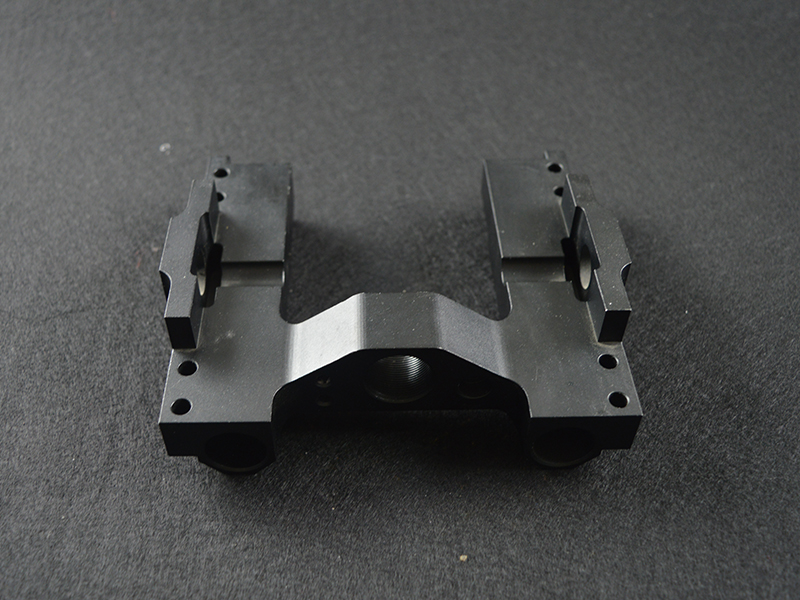

Step 6: Finishing Touches

After machining, your parts might need additional finishing processes like anodizing, plating, or painting. These processes can improve the part’s appearance, durability, or functionality.

Step 7: Quality Check and Delivery

Before shipping, every part undergoes a final quality inspection. The shop will verify dimensions, check surface finishes, and ensure that everything meets your requirements.

Once approved, your parts will be carefully packaged and shipped to your location.

Choosing the Right Materials for Your Project

Metal Options

Aluminum – Great for lightweight applications

- 6061-T6: The workhorse of aluminum alloys

- 7075-T6: Stronger but less machinable

- 5052: Excellent corrosion resistance

Steel – For strength and durability

- Carbon Steel: Economical choice for many applications

- Stainless Steel: Corrosion-resistant option

- Alloy Steel: High strength for demanding applications

Specialty Metals

- Titanium: Lightweight and strong, perfect for aerospace

- Brass: Excellent machinability and appearance

- Copper: Good conductivity for electrical applications

Plastic Materials

Acetal (Delrin) – Good dimensional stability

PEEK – High-performance plastic for demanding applications

Nylon – Strong and wear-resistant

PTFE (Teflon) – Chemical resistant with low friction

How to Choose the Right Material

When selecting a material, consider:

- Strength and durability requirements

- Environmental factors (temperature, chemicals)

Don’t be afraid to ask your CNC shop for recommendations. They’ve worked with all kinds of materials and can help you make the best choice for your application.

Understanding CNC Machining Processes

Milling – For Complex Shapes

CNC milling uses rotating cutting tools to remove material from a workpiece. It’s great for creating complex shapes, slots, and pockets. Modern 5-axis milling machines can create incredibly intricate parts from multiple angles.

Turning – For Round Parts

CNC turning is used to create cylindrical parts like shafts and bushings. The workpiece rotates while a cutting tool removes material to create the desired shape.

Drilling – For Precision Holes

CNC drilling creates precise holes with consistent diameter and depth. It’s often used in conjunction with milling and turning for more complex parts.

Finishing Processes

After machining, parts might need additional processes:

- Anodizing: Improves corrosion resistance and adds color

- Plating: Adds a decorative or protective coating

- Painting: For aesthetics and protection

- Heat Treatment: Improves material properties

Quality Control – Ensuring Your Parts Are Perfect

What to Look for in a Quality CNC Shop

A good CNC shop will have:

- Certifications: ISO 9001, AS9100, or other relevant certifications

- Modern Equipment: Up-to-date machines with good accuracy

- Skilled Operators: Experienced technicians who know what they’re doing

- Quality Control Processes: Systems to ensure every part meets specifications

Inspection Equipment

Reputable shops use advanced inspection equipment:

- Coordinate Measuring Machines (CMM): For precise 3D measurements

- Optical Comparators: For checking complex shapes

- Surface Roughness Testers: For verifying surface finishes

- Hardness Testers: For checking material properties

How to Choose the Right CNC Machining Service Provider

Do Your Homework

Before choosing a CNC shop, do some research:

- Check their website and portfolio

- Visit the facility if possible

Ask the Right Questions

When evaluating a CNC shop, ask:

- What industries do you specialize in?

- What materials do you work with?

- What tolerances can you achieve?

- What’s your typical lead time?

- Do you offer design services?

- What quality certifications do you have?

Consider Location

While it’s possible to work with shops anywhere in the world, there are advantages to working with local providers:

- Ability to visit the facility

- Potential cost savings on shipping

Get Multiple Quotes

Don’t just go with the first quote you receive. Get quotes from several different shops to compare:

Remember, the lowest price isn’t always the best value. Consider the shop’s reputation, experience, and quality standards when making your decision.

Cost Considerations – Understanding the Price

What Affects the Cost of Custom CNC Machining?

Several factors influence the cost of custom parts:

- Design Complexity: More complex parts take longer to machine

- Material Costs: Some materials are more expensive than others

- Tolerance Requirements: Tighter tolerances require more precise machining

- Production Volume: Larger quantities often mean lower per-unit costs

- Lead Time: Rush orders usually cost more

How to Keep Costs Under Control

Here are some tips for managing costs:

- Simplify Designs: Complex features add time and cost

- Choose Standard Materials: Specialty materials can be expensive

- Optimize Tolerances: Only specify tight tolerances where necessary

- Consider Production Volume: Higher volumes mean lower per-unit costs

- Plan Ahead: Rush orders cost more than standard lead times

Custom CNC Machining Applications by Industry

Aerospace Industry

Custom CNC parts are critical in aerospace applications where precision and reliability are essential. From engine components to structural parts, every component must meet strict standards.

Automotive Industry

The automotive industry relies heavily on custom CNC machining for both production parts and prototypes. Custom parts help improve performance, reduce weight, and enhance safety.

Medical Device Industry

Medical devices require extremely precise components made from biocompatible materials. Custom CNC machining ensures these critical parts meet the highest standards.

Electronics Industry

The electronics industry uses custom CNC parts for enclosures, heat sinks, and other components. Precision machining ensures these parts work perfectly with delicate electronic components.

Industrial Equipment

Manufacturers of industrial equipment depend on custom CNC parts for their machines. These parts are often designed to handle heavy loads and harsh environments.

Getting the Most Out of Your CNC Machining Partner

Communication is Key

The key to a successful custom machining project is good communication. Be clear about your requirements, and don’t hesitate to ask questions. A good CNC shop will keep you informed throughout the process.

Provide Detailed Specifications

The more information you provide, the better the results will be. Include:

- Surface finish requirements

Be Open to Suggestions

Experienced CNC shops can often suggest design improvements that will save you time and money. Be open to their recommendations – they have the expertise to know what works best.

Plan for the Future

When designing custom parts, consider future production needs. A good design today can save you money in the long run when you need to scale up production.

Frequently Asked Questions

Q: How long does custom CNC machining take?

A: Lead times vary depending on the complexity of the part, material, and quantity. Prototypes typically take 3-7 business days, while production runs can take 1-4 weeks.

Q: What file formats do you accept?

A: Most CNC shops accept all major CAD formats including STEP, IGES, STL, SolidWorks, AutoCAD, and Fusion 360.

Q: What tolerances can you achieve?

A: Standard tolerances are around ±0.01 mm (0.0004″), but tighter tolerances are possible for critical applications.

Q: Can you work with my existing designs?

A: Yes, most shops can work with your existing designs. They might suggest improvements for manufacturability, but the final decision is always yours.

Q: Do you offer design services?

A: Many CNC shops offer design services, including DFM analysis and design optimization. This can be especially helpful if you’re new to designing parts for CNC machining.

Q: What materials do you work with?

A: Most shops work with a wide range of materials including aluminum, steel, stainless steel, titanium, brass, and various plastics.

Q: Can you handle large production runs?

A: Yes, most CNC shops can handle everything from prototypes to large production runs. Many offer volume discounts for larger orders.

Q: How do you ensure quality?

A: Reputable shops have comprehensive quality control processes including first article inspection, in-process checks, and final inspection before shipment.

Q: What if I’m not satisfied with the parts?

A: A good CNC shop will work with you to resolve any issues. Many offer guarantees on their work.

Q: How do I get started?

A: The best way to get started is to contact a CNC shop with your project requirements. They’ll guide you through the process and help you get the parts you need.

Disclaimer

- All information, opinions, and data contained in this article are for the purpose of information transmission only and do not constitute any advice on investment, transactions, law, medical care, or other matters.

- The content of the article is compiled based on public information or created based on the author’s personal understanding. Although every effort is made to ensure accuracy, it does not guarantee the completeness, accuracy, and timeliness of the information, nor does it bear any responsibility for any losses caused by the use of the content of this article.

- If the article involves third-party opinions, pictures, data, and other content, the copyright belongs to the original author. In case of infringement, please contact us for deletion.

- Readers should make independent decisions based on their actual situation and combined with professional opinions. The user shall bear all consequences arising from the use of the content of this article.

CNC Machining Customized Service Guide | Helping You Get the Perfect Parts Every Time

Ready to get started on your custom CNC machining project? Contact us today for a free quote and expert consultation.