The medical device industry demands the highest levels of quality, accuracy, and reliability. One of the key manufacturing processes that enable the creation of complex and precise components for medical devices is CNC machining.

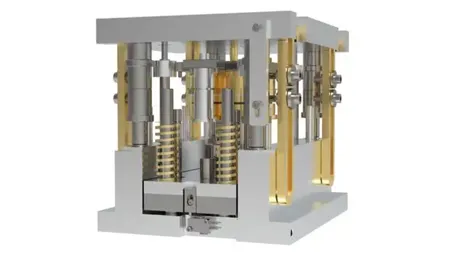

CNC (Computer Numerical Control) machining offers unrivaled precision when it comes to crafting custom parts for medical applications. The ability to control the machining process with extreme accuracy ensures that each component meets the strict specifications and tolerances required in the medical field.

Custom parts play a crucial role in medical device manufacturing. Different medical devices have unique designs and functions, and CNC machining allows for the creation of tailor-made components that perfectly fit the specific needs of each device. Whether it’s a tiny implantable part or a complex surgical instrument, CNC machining can produce parts with intricate geometries and features that are essential for optimal performance and patient safety.

The precision offered by CNC machining is paramount in the medical sector. Components must be manufactured to exact dimensions to ensure proper fit, functionality, and biocompatibility. Even the slightest deviation can have significant implications for the effectiveness and safety of the medical device.

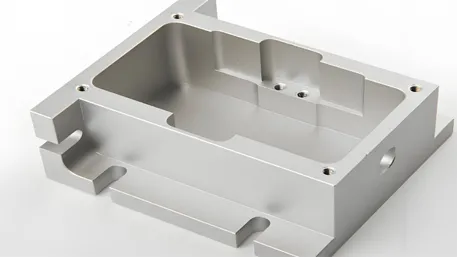

Moreover, CNC machining enables the use of a wide range of materials suitable for medical applications, such as stainless steel, titanium, and various biocompatible plastics. These materials can be machined with precision to meet the specific mechanical and chemical properties needed for different medical devices.

In addition to precision and customizability, CNC machining also offers repeatability. This means that once a successful manufacturing process is established, identical parts can be produced consistently, ensuring uniformity and quality across multiple batches of medical devices.

Quality control is an integral part of CNC machining in medical device manufacturing. Advanced inspection techniques and measurement tools are employed to verify that the produced parts meet the strict regulatory standards and quality requirements of the medical industry.

In conclusion, CNC machining is a vital technology in the medical device manufacturing landscape. Its ability to provide custom parts with exceptional precision helps drive innovation in the field, improving patient care and outcomes. As the medical industry continues to advance, the role of CNC machining is likely to become even more critical in meeting the ever-increasing demands for sophisticated and reliable medical devices.

We are committed to staying at the forefront of CNC machining technologies and techniques to continue delivering high-quality, custom parts for the medical device sector, making a positive impact on healthcare worldwide.

Do you have any questions or thoughts about CNC machining in medical device manufacturing? Share your comments below!