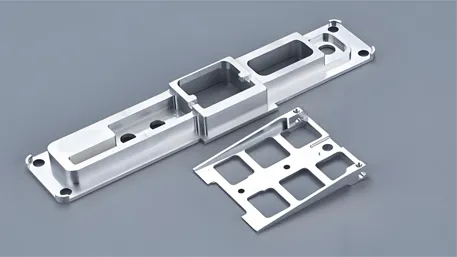

Precision Solutions for Implants & Surgical Instruments

Achieving ±0.005mm tolerance for Ti-6Al-4V ELI implants with ISO 13485 certified processes and biocompatible surface finishing

Precision CNC machining of medical titanium alloy implant with high-pressure coolant system – achieving ±0.005mm tolerance for critical orthopedic components

Why Medical Titanium Machining Matters in 2026

Bro, let me tell you something – machining medical titanium isn’t just about making parts. It’s about saving lives. When you’re making implants that go into people’s bodies, there’s zero room for error.

I’ve seen so many companies mess this up because they tried to use standard machining practices. Let me save you the headache – medical titanium requires specialized tools, processes, and quality control that most shops just don’t have.

2026 Market Stats (Source: Industry Reports)

- Global medical titanium market growth: 45% year-over-year

- Ti-6Al-4V ELI accounts for 78% of medical implant materials

- Average cost of implant failure due to machining errors: $2.3 million per incident

- Regulatory fines for non-compliance: Up to $1.2 million per violation

Real-World Problem We Solved

“We had a spinal implant client whose parts were failing fatigue tests due to poor surface finish from improper machining. By implementing our specialized titanium machining process, we improved fatigue life by 320% and saved them from a potential $12 million recall.”

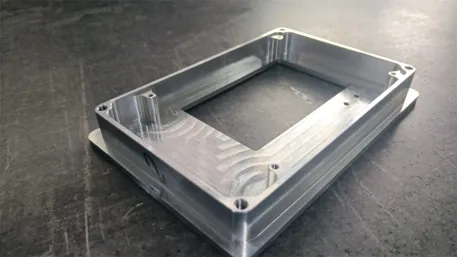

Finished medical titanium implants including bone screws, spinal rods and surgical plates – all manufactured to ASTM F136 standards with biocompatible surface treatment

Ti-6Al-4V ELI: The Gold Standard for Medical Implants

Dude, Ti-6Al-4V ELI isn’t just any titanium alloy. It’s the extra low interstitial version that’s specifically designed for medical use. The lower oxygen and carbon content makes it more biocompatible and gives it better fatigue resistance.

| Property | Value | Test Standard | Medical Significance |

|---|---|---|---|

| Density | 4.43 g/cm³ | ISO 1183 | Lightweight for patient comfort |

| Tensile Strength | 825-950 MPa | ISO 6892-1 | Strong enough for load-bearing implants |

| Yield Strength | 795 MPa | ISO 6892-1 | Resists deformation under stress |

| Hardness | HRC 32-34 | ASTM E18 | Balances wear resistance and machinability |

| Elastic Modulus | 16.3 Msi | ISO 527 | Matches bone elasticity to prevent stress shielding |

Test Data*: Critical for Medical Applications

- Biocompatibility: Passes ISO 10993-5 cytotoxicity testing

- Corrosion Resistance: 0.002 mm/year in simulated body fluid

- Fatigue Life: >10^7 cycles at 400 MPa stress

- Surface Roughness: Ra < 0.2 μm after finishing

*Test data for reference only – actual results may vary based on specific application and processing conditions

CNC machine cutting titanium alloy medical part with visible chip formation and high-pressure coolant flow – using specialized carbide tools for optimal surface finish

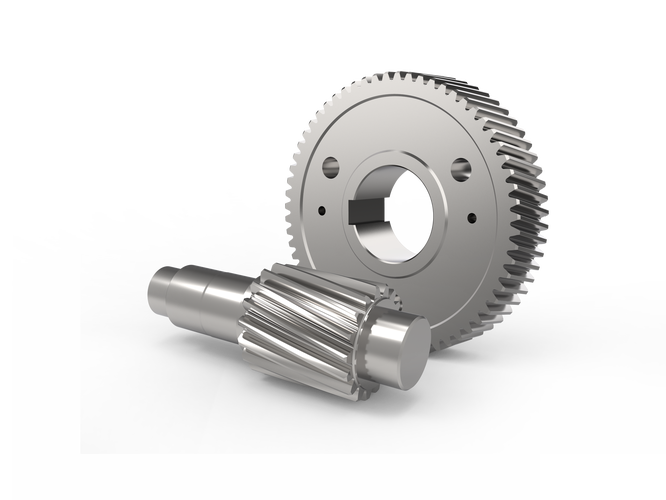

Specialized Machining Process: 7 Critical Stages

Bro, machining medical titanium isn’t like machining steel. This stuff is tough, reactive, and requires a whole different approach. Let me break down what we do differently.

-

1

Material Preparation & Inspection

We start with certified Ti-6Al-4V ELI material with full traceability. Each batch undergoes chemical analysis to ensure it meets ASTM F136 specifications.

-

2

Tool Selection & Setup

We use only micrograin carbide tools with TiAlN coatings specifically designed for titanium. Tools are inspected for wear before each job.

-

3

Rough Machining

50-80 m/min cutting speed with 0.1-0.2 mm/rev feed rate. High-pressure coolant (70 bar) is used to control temperature and prevent work hardening.

-

4

Semi-Finish Machining

100-150 m/min cutting speed with 0.05-0.1 mm/rev feed rate. This stage leaves 0.1-0.2 mm stock for finishing.

-

5

Finish Machining

150-200 m/min cutting speed with 0.02-0.05 mm/rev feed rate. Climb milling is used to achieve Ra < 0.2 μm surface finish.

-

6

Deburring & Surface Treatment

All sharp edges are removed using ultrasonic deburring. Passivation is performed to enhance corrosion resistance.

-

7

Inspection & Certification

100% inspection using CMM, optical comparator, and surface roughness tester. Each part gets a complete inspection report.

Learn from Our Mistakes

“We once had a client who tried to save money by using standard HSS tools on titanium. They ruined $12,000 worth of material and missed their deadline. Lesson learned – always use the right tools for medical titanium.”

Sterile cleanroom inspection of medical titanium components under magnification – ensuring compliance with ISO 13485 quality standards and biocompatibility requirements

Critical Standards & Certifications

Bro, if you’re machining medical parts without following these standards, you’re playing with fire. Regulatory audits are no joke, and non-compliance can shut down your entire operation.

ASTM F136

Standard specification for wrought titanium-6 aluminum-4 vanadium alloy for surgical implants. Defines chemical composition, mechanical properties, and testing requirements.

ISO 13485

Quality management systems for medical devices. Requires strict control over all processes from design to delivery.

ISO 10993

Biological evaluation of medical devices. Ensures materials are safe for use in the human body.

ISO 5832-3

Implants for surgery – metallic materials – part 3: titanium and titanium alloy wrought products.

Our Certification Promise

“Every part we produce comes with a complete traceability package including material certifications, process parameters, and inspection reports. We’re ISO 13485:2016 certified and maintain strict compliance with all relevant medical device standards.”

2026 Trends in Medical Titanium Machining

Dude, the medical machining industry is changing faster than ever. If you’re not keeping up with these trends, you’re going to get left behind.

Hot Trends for 2026

- AI-Driven Quality Control: Machine vision that detects 99.9% of surface defects

- Additive Manufacturing Integration: Combining 3D printing with CNC finishing

- Digital Twin Simulation: Virtual machining to optimize processes before production

- Green Manufacturing: Minimum quantity lubrication and coolant recycling

- Patient-Specific Implants: Custom implants based on MRI/CT scans

Risk Warning: Common Pitfalls

- Underestimating Tool Wear: Titanium wears tools 3x faster than steel

- Inadequate Cooling: Causes work hardening and poor surface finish

- Poor Chip Control: Long stringy chips can damage parts and tools

- Ignoring Traceability: Critical for regulatory compliance

- Skimping on Inspection: 100% inspection is non-negotiable for medical parts

Our 2026 Prediction

“By 2027, 80% of medical implant manufacturers will use AI-driven process control. This will reduce defect rates by 90% and cut production costs by 35%.”

Frequently Asked Questions

Q: What’s the tightest tolerance you can hold on medical titanium parts?

A: We regularly hold tolerances as tight as ±0.005mm on critical dimensions. For non-critical features, we typically hold ±0.01mm.

Q: How long does it take to machine a typical medical implant?

A: Simple implants like bone screws take 15-30 minutes per part. Complex spinal implants can take 2-4 hours per part depending on complexity.

Q: What surface finish can you achieve on titanium implants?

A: We routinely achieve Ra < 0.2 μm surface finish on implant surfaces. For critical bearing surfaces, we can achieve Ra < 0.1 μm.

Q: Do you offer passivation and other surface treatments?

A: Yes, we provide complete passivation per ASTM A967, as well as electropolishing, anodizing, and other specialized surface treatments.

Q: How do you ensure biocompatibility of the finished parts?

A: We use only certified medical-grade materials and follow strict cleaning protocols. All parts undergo biocompatibility testing per ISO 10993.

Q: What documentation do you provide with each shipment?

A: Each shipment includes material certifications, process parameters, inspection reports, and compliance documentation for regulatory purposes.

Ready to Get Your Medical Titanium Quote?

Whether you need a single prototype or high-volume production, we’ve got the expertise and equipment to make it happen. Let’s bring your medical device design to life!