About Goldcattle

Xiamen Goldcattle Plastic & Metal Products Co., Ltd. is a professional manufacturer specializing in precision injection molding parts, precision machined components, stamping parts, and plastic injection molding products. As an OEM and ODM factory, we have established ourselves as a national high-tech enterprise with over 26 years of manufacturing expertise.

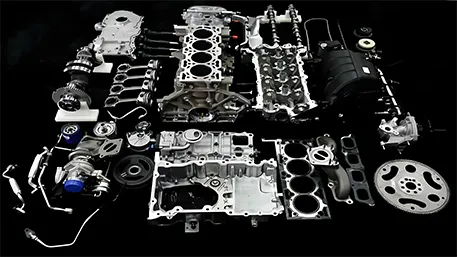

Our company has built a reputation for excellence in the manufacturing industry, serving clients across various sectors including automotive, machinery, medical devices, aerospace, and consumer electronics. We are committed to delivering high-quality, precision-engineered components that meet the most demanding specifications.

Our Manufacturing Philosophy

At Goldcattle, we believe that precision manufacturing is both an art and a science. Our approach combines cutting-edge technology with decades of craftsmanship to deliver components that exceed our clients’ expectations.

We invest heavily in employee training and development, ensuring that our team stays at the forefront of manufacturing technology and best practices. This commitment to excellence has earned us the trust of clients worldwide.

Technical Capabilities

Goldcattle is equipped with state-of-the-art CNC machining centers and testing equipment, enabling us to achieve high-precision, high-efficiency manufacturing of complex components. Our technical capabilities are supported by a team of highly skilled engineers and technicians with extensive experience in precision machining.

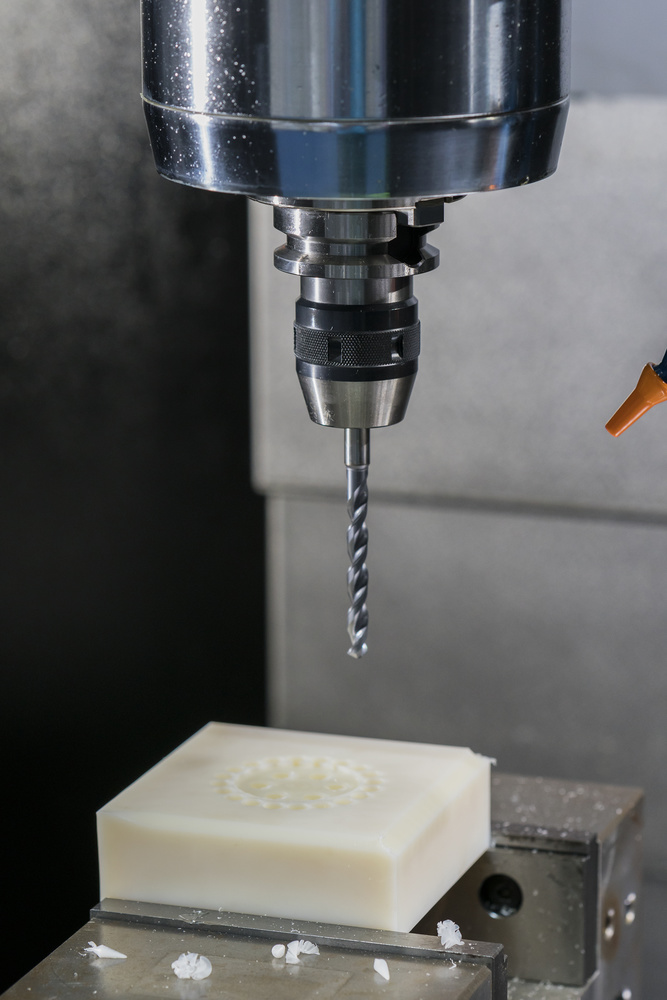

CNC Machining Centers

Our facility houses advanced CNC machining centers, including 5-axis equipment capable of achieving ±0.005mm precision. These machines are equipped with high-precision linear scales and temperature compensation systems to ensure stability and accuracy.

- 5-axis simultaneous machining capability

- High-precision linear scales

- Temperature compensation systems

- Multi-material compatibility

5-Axis Machining

5-axis machining technology is one of Goldcattle’s core competencies, enabling us to machine complex parts in a single setup. This technology is particularly suited for aerospace components and other high-precision applications.

- Complex shape machining

- ±0.005mm precision

- Aerospace applications

- Medical device components

Precision Inspection

To ensure product quality, Goldcattle is equipped with advanced inspection equipment, including coordinate measuring machines, optical projectors, and surface roughness testers, providing detailed inspection reports for each production batch.

- Coordinate measuring machines

- Optical projectors

- Surface roughness testers

- Full-dimensional inspection reports

Technical Parameter Comparison

Goldcattle’s Technical Advantages

Our combination of advanced equipment, skilled workforce, and rigorous quality control processes allows us to consistently deliver components that meet the most demanding specifications. We continuously invest in new technologies and training to maintain our competitive edge in the global marketplace.

2026 CNC Machining Trends & Goldcattle Practices

2026 Industry Trends

The global CNC machining market is projected to reach $185 billion by 2026, with China accounting for 28.1% of this market. Key trends include AI-driven process optimization, sustainable manufacturing practices, and increased demand for micro-precision components.

AI Path Optimization

Artificial intelligence applications in CNC machining represent a significant trend for 2026. Goldcattle has implemented AI path optimization technology in multiple projects, achieving significant improvements in production efficiency and product quality through real-time parameter adjustments and intelligent path planning.

Technical Advantages

- Real-time parameter adjustment: AI systems can adjust cutting parameters in real-time based on machining conditions

- Efficiency improvement: 2025 tests showed AI optimization increased production efficiency by 25%

- Tool wear reduction: Intelligent path planning reduced tool wear by 30%

- Surface quality improvement: AI optimization improved part surface quality by 18%

Sustainable Materials

Environmental protection and sustainable development are important trends in manufacturing. Goldcattle actively promotes the use of sustainable materials, achieving significant environmental benefits and cost savings through recycled material usage and process optimization.

Environmental Achievements

- Recycled material usage: 40% of materials come from recycled resources

- Carbon emission reduction: Process optimization reduced carbon emissions by 18%

- Material cost reduction: Recycled material usage reduced material costs by 12%

- Bio-based plastics: Actively promoting the application of bio-based plastics

Micro-precision/Hybrid Manufacturing

Micro-precision machining and hybrid manufacturing technologies will be important development directions in 2026. Goldcattle has invested significant R&D resources in this area, enabling ultra-high precision machining and complex structure manufacturing.

Ultra-high Precision

Achieving ±0.0005mm machining precision

Complex Structures

Hybrid manufacturing increased complex structure realization by 40%

Weight Reduction

Advanced design reduced part weight by 25%

EV/Medical Applications

Particularly suited for electric vehicle and medical device fields

Goldcattle Technology Roadmap

Service Offerings

Goldcattle provides comprehensive precision manufacturing services to meet the diverse needs of clients across different industries. Our capabilities span from initial design consultation to final production and delivery, ensuring a seamless experience for our customers.

CNC Machining

Comprehensive CNC machining services including milling, turning, drilling, boring, and grinding to meet various precision and complexity requirements.

- ✓ CNC milled parts

- ✓ CNC turned parts

- ✓ CNC drilled parts

- ✓ CNC bored parts

- ✓ CNC ground parts

Mold Making

Professional mold design and manufacturing team providing single-cavity, double-cavity, thin-wall, thermoplastic, and precision molds to meet different production needs.

- ✓ Single-cavity molds

- ✓ Double-cavity molds

- ✓ Thin-wall molds

- ✓ Thermoplastic molds

- ✓ Precision molds

Injection Molding

Various injection molding services including single-color, multi-color, insert, foam, and micro-injection molding for various engineering plastics to meet different industry needs.

- ✓ Single-color parts

- ✓ Multi-color parts

- ✓ Insert molded parts

- ✓ Foam molded parts

- ✓ Micro-injection parts

3D Printing

Professional 3D printing services including model making, functional part printing, and art production for various plastic materials to meet rapid prototyping and small-batch production needs.

- ✓ 3D printed models

- ✓ 3D printed parts

- ✓ 3D printed plastics

- ✓ 3D printed art

- ✓ 3D printed toys

Stamping

Metal stamping, bending, drawing, spinning, and casting services for various metal materials to meet automotive, electronics, and appliance industry needs.

- ✓ Metal stamped parts

- ✓ Metal bent parts

- ✓ Metal drawn parts

- ✓ Metal spun parts

- ✓ Metal cast parts

Industry Applications

Our products are widely used in automotive, machinery, medical, aerospace, and electronic device industries, providing customized precision component solutions.

- ✓ Automotive industry

- ✓ Machinery industry

- ✓ Medical industry

- ✓ Aerospace

- ✓ Electronic devices

Our Service Commitment

At Goldcattle, we are committed to providing our clients with the highest quality products and services. Our team of experienced engineers and technicians works closely with clients to understand their specific needs and develop customized solutions that meet their requirements.

Success Cases

Goldcattle has built a reputation for excellence through our successful completion of numerous high-profile projects across various industries. Our commitment to quality, precision, and customer satisfaction has earned us the trust of clients worldwide.

Why Clients Choose Goldcattle

26+ years of manufacturing expertise

State-of-the-art equipment and technology

ISO9001 quality management system

Competitive pricing and fast delivery

Customized solutions for unique needs

Comprehensive after-sales support

CNC vs Traditional Machining: 2026 Selection Guide

Understanding the differences between CNC machining and traditional machining is crucial for selecting the most appropriate manufacturing method for your specific needs. Each approach has its own advantages and disadvantages depending on the application requirements.

Comparison Table

Recommended for CNC Machining

- High precision requirements: Tolerances below ±0.1mm

- High surface quality requirements: Need for smooth surfaces or special textures

- Complex shapes or curved surfaces: Complex structures difficult to achieve with traditional machining

- Large batch production: Need for efficient, stable production processes

- Urgent delivery requirements: Need for quick response orders

Consider Traditional Machining

- Simple shape parts: Structurally simple standard parts

- Small batch prototyping: Samples or small batch testing

- Low precision requirements: Applications with less demanding precision needs

- Budget constraints: Projects with strict cost control

- Non-urgent orders: Projects with less strict timing requirements

Goldcattle Advantage

Both Machining Capabilities

Choose optimal solution based on needs

Professional Technical Team

Provide professional technical advice

Optimal Solutions

Balance quality, cost, and delivery

One-stop Service

Full service from design to delivery

Quality Assurance

Strict quality control processes

Frequently Asked Questions

We’ve compiled answers to some of the most common questions our clients have about CNC machining and our services. If you have additional questions, please don’t hesitate to contact us.

What precision can CNC machining achieve?

Goldcattle’s CNC machining precision can reach ±0.005mm. For parts with special requirements, using 5-axis machining centers and advanced inspection equipment, we can achieve ultra-high precision of ±0.0005mm. Our equipment is equipped with high-precision linear scales and temperature compensation systems to ensure machining precision stability.

What materials can be machined?

We can machine various metal materials including aluminum alloys, stainless steel, titanium alloys, copper alloys, magnesium alloys, as well as engineering plastics such as POM, PA, PEEK, etc. We also have extensive machining experience with special materials like high-temperature alloys and composite materials. Each material has specialized machining parameters and tool selection to ensure optimal machining results.

How long is the machining cycle?

The machining cycle depends on part complexity, precision requirements, and quantity. Generally, sample machining takes 3-7 days, small-batch production takes 7-15 days, and large-batch production takes 15-30 days. We use advanced production management systems to track production progress in real-time and ensure on-time delivery. For urgent orders, we can provide expedited services.

How is product quality ensured?

We have established a comprehensive quality assurance system and are ISO9001:2015 certified. Each process has strict quality inspection, using coordinate measuring machines, optical projectors, surface roughness testers, and other advanced inspection equipment. We also implement SPC statistical process control to monitor production processes in real-time, ensuring product quality stability and consistency.

What are the costs for small batches in 2026?

Small-batch machining costs depend on part complexity, material costs, and machining time. For 2026, we offer small-batch discount policies for orders of 100-500 pieces with more favorable pricing. Additionally, we use advanced optimization software to reduce machining time and material waste, thereby lowering costs. Specific quotations require evaluation based on your part drawings.

What are common defects and how to avoid them?

Common defects in CNC machining include dimensional deviations, excessive surface roughness, deformation, cracks, etc. We avoid these issues through:

- • Optimizing machining processes and parameters

- • Using appropriate fixtures and clamping methods

- • Controlling machining temperature

- • Selecting appropriate tools and cutting parameters

- • Implementing strict quality inspection

Our technical team has extensive experience and can identify potential quality risks in advance.

What eco-friendly material options are available?

We offer various eco-friendly material options including:

- • Recycled metal materials

- • Bio-based plastics such as PLA, PHA, etc.

- • Water-based coatings and chromium-free passivation treatment

- • Biodegradable materials

We also implement green manufacturing solutions including: optimizing tool paths to reduce material waste, using MQL minimum quantity lubrication technology, recycling cutting fluids, etc. Our goal is to minimize environmental impact while ensuring product quality.

What are the top 5 pitfalls in CNC customization?

The top 5 issues in CNC customization:

- • Inconsistent tolerance understanding

- • Unclear surface treatment requirements

- • Inappropriate material selection

- • Unreasonable machining processes

- • Unclear quality standards

Goldcattle solutions:

- • Provide detailed technical communication

- • Establish clear technical specifications

- • Provide material selection recommendations

- • Optimize machining processes

- • Establish clear quality standards

Our project engineers will follow up throughout the process to ensure each环节 is properly handled.

Contact Us

Whatever your precision manufacturing needs may be, we will provide you with professional solutions and high-quality services. Our team of experts is ready to assist you with your project requirements.

Service Process

- Needs Analysis: Understand your product requirements, production scale, budget, and timeline

- Design Proposal: Provide 2-3 design solutions including 3D models and technical parameters

- Cost Quotation: Detailed cost analysis and quotation including mold cost and production timeline

- Confirmation & Order: Sign contract, pay deposit, start mold manufacturing

- Manufacturing Process: Weekly progress reports, key milestone confirmations

- Trial & Validation: Mold testing after completion, provide samples for confirmation

- Delivery & Training: Mold delivery, provide operation training and maintenance guidance

Request a Quote

Our Service Packages

Our Commitment

26 Years Experience

Rich industry experience

National High-Tech Enterprise

Technical capability certification

ISO9001 Certified

Quality management system

±0.005mm Precision

High precision guarantee

7-15 Day Delivery

Quick response

100% quality inspection

Quality assurance

Liu Gong / Goldcattle CNC Director

20 years of experience, led 500+ precision parts projects