1. Fundamental Theory of CNC Machining Precision

1.1 Precision Grade Classification System

- IT01-IT5: High precision grade, tolerance range from micrometers to sub-micrometers

- IT6-IT8: Medium precision grade, tolerance range from micrometers to tens of micrometers

- IT9-IT18: Normal grade, tolerance range above one hundred micrometers

- Normal Grade (P): Positioning accuracy ≤0.02mm, repeatability ≤0.015mm

- Precision Grade (M): Positioning accuracy ≤0.012mm, repeatability ≤0.008mm

- High Precision Grade (G): Positioning accuracy ≤0.004mm, repeatability ≤0.003mm

1.2 Surface Quality Control Indicators

|

Machining Grade

|

Ra Value Range

|

Surface Characteristics

|

Typical Applications

|

|

Rough Machining

|

12.5-20μm

|

Obvious tool marks

|

Structural parts

|

|

Semi-finishing

|

3.2-6.3μm

|

Visible tool marks

|

General components

|

|

Finishing

|

0.8-1.6μm

|

Slight tool marks

|

Fitting parts

|

|

Precision Machining

|

0.2-0.4μm

|

Mirror finish

|

Precision components

|

2. Analysis of Factors Affecting CNC Machining Precision

2.1 Machine Tool Factors

- Spindle radial runout: Every 0.001mm increase causes 0.003mm machining error

- Spindle axial runout: Directly affects end face machining precision

- Spindle speed stability: ±5% speed fluctuation increases surface roughness by 30%

- Ball screw precision grade: C3 grade screw positioning error ≤0.008mm/300mm

- Guideway precision: Straightness error of 0.01mm per meter causes workpiece parallelism error

- Servo system response: Response speed directly affects contour machining precision

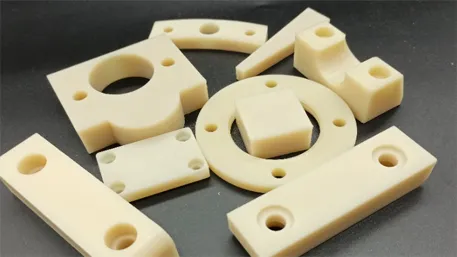

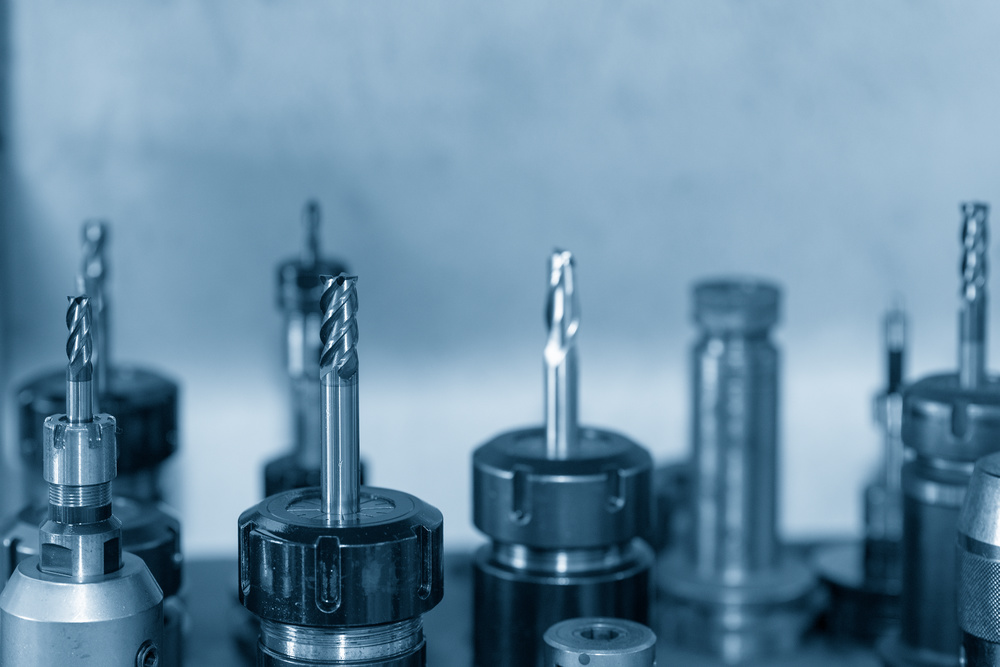

2.2 Tool Factors

- High-speed steel tools: Suitable for low-speed machining, precision life approximately 8 hours

- Carbide tools: Suitable for high-speed machining, precision life up to 40 hours

- Cubic boron nitride tools: Suitable for super-hard materials, precision up to IT5 grade

- Rake angle selection: 15-20° for aluminum alloys, 5-10° for steel parts

- Clearance angle selection: 8-12° for finishing, 5-8° for roughing

- Tool nose angle: Affects chip flow direction and cutting force distribution

- Tool wear of 0.01mm increases part dimension error by 0.015mm

- Flank wear VB value controlled within 0.1-0.3mm range

- Implement tool life management system

2.3 Process Parameter Settings

|

Material

|

Tool Material

|

Cutting Speed (m/min)

|

Feed Rate (mm/r)

|

Depth of Cut (mm)

|

|

Aluminum Alloy

|

Carbide

|

300-600

|

0.1-0.3

|

1-5

|

|

Carbon Steel

|

Carbide

|

100-300

|

0.1-0.25

|

1-4

|

|

Stainless Steel

|

Carbide

|

50-150

|

0.05-0.2

|

0.5-2

|

|

Titanium Alloy

|

Carbide

|

30-100

|

0.05-0.15

|

0.3-1.5

|

- Adopt climb milling to reduce tool wear

- Use layer cutting for roughing, contour machining for finishing

- Reasonably arrange cutting sequence to avoid workpiece deformation

2.4 Environmental Factor Control

- Precision machining workshop temperature: 20±1℃

- Temperature change rate: No more than 0.5℃ per hour

- Relative humidity: 45-65%

- Machine tool installed with anti-vibration pads, vibration amplitude controlled within 0.002mm

- Keep away from vibration sources such as stamping and forging equipment

- Adopt vibration isolation foundation design

3. CNC Machining Precision Control Technology

3.1 Error Compensation Technology

- Use laser interferometer to measure machine geometric errors

- Perform error compensation through CNC system parameters

- Can improve precision by 20-40%

- Install temperature sensors on machine tools

- Establish thermal error prediction model

- Real-time compensation of thermal deformation errors

- Tool length compensation: Compensate for tool wear and replacement errors

- Tool radius compensation: Ensure contour machining precision

- Tool wear compensation: Automatically compensate wear based on machining time

3.2 High-Precision Machining Processes

- Spindle speed: 8000-40000rpm

- Feed rate: 20-60m/min

- Surface roughness can reach Ra 0.4-0.8μm

- Cutting speed: 1000-5000m/min

- Feed rate: 0.001-0.01mm/r

- Machining precision can reach above IT5 grade

- Machining precision: ±0.002mm

- Surface roughness: Ra 0.1-0.8μm

- Suitable for complex shapes and hard materials

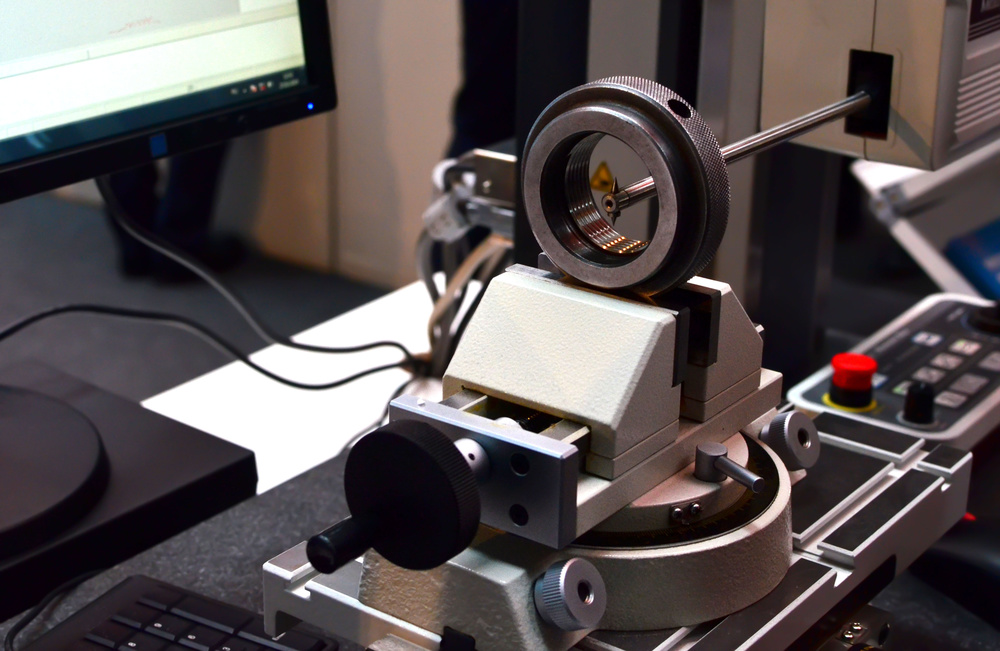

3.3 Quality Inspection Technology

- Laser measuring instrument: Precision ±0.001mm

- Probe measuring system: Repeatability ±0.0005mm

- Real-time monitoring of machining process

- Coordinate measuring machine: Measurement accuracy ±0.001mm

- Roundness tester: Measurement accuracy ±0.0001mm

- Surface roughness tester: Measurement range 0.001-16μm

4. Practical Application Case Analysis

4.1 Aerospace Component Machining Case

- Use 5-axis machining center

- Spindle speed: 18000rpm, feed rate: 30m/min

- Tool: Ultra-fine grain carbide with TiAlN coating

- Cutting parameters: V=80m/min, f=0.1mm/r, ap=0.5mm

- Machining in temperature-controlled workshop, temperature controlled at 20±0.5℃

- Use on-machine laser measuring system

- Conduct sampling inspection every 10 pieces

- Dimensional accuracy: ±0.003mm

- Surface roughness: Ra 0.15μm

- Qualification rate: 98.5%

4.2 Precision Mold Machining Case

- Rough machining: High-speed milling to remove most stock

- Semi-finishing: Ball end mill, leaving 0.3mm stock

- Heat treatment: Quenching and tempering to HRC48-52

- Finishing: High-speed milling to meet dimensional requirements

- Polishing: Manual polishing to Ra 0.4μm

- Use high-speed machining center with 15000rpm spindle

- Use solid carbide ball end mills

- Adopt climb milling to reduce tool wear

- Optimize machining path to avoid overcutting

4.3 Medical Device Machining Case

- Complex surface machining requiring 5-axis linkage

- High surface quality requirements, needing mirror finish

- Biocompatibility requirements, no burrs or defects

- Forging blank pretreatment

- CNC turning to machine datum surfaces

- 5-axis milling to machine complex surfaces

- Grinding to improve precision

- Polishing to meet surface requirements

5. CNC Machining Precision Improvement Practical Guide

5.1 Equipment Selection Recommendations

- Economic CNC machining center

- Spindle speed: 6000-8000rpm

- Positioning accuracy: ±0.015mm

- Standard CNC machining center

- Spindle speed: 8000-12000rpm

- Positioning accuracy: ±0.008mm

- High-precision CNC machining center

- Spindle speed: 12000-24000rpm

- Positioning accuracy: ±0.003mm

5.2 Tool Selection Strategy

- Aluminum alloys: High-speed steel, carbide, diamond tools

- Steel parts: Carbide, coated tools

- Stainless steel: Ultra-fine grain carbide, CBN tools

- Titanium alloys: Ultra-fine grain carbide, cermet tools

- Roughing: Inserted tools, high-speed steel tools

- Semi-finishing: Solid carbide tools

- Finishing: Coated tools, ultra-fine grain tools

5.3 Process Optimization Methods

- Determine initial parameters based on material and tool

- Conduct trial cutting tests and record machining results

- Analyze surface quality and dimensional accuracy

- Adjust parameters and repeat tests

- Determine optimal parameter combination

- Reduce empty travel time to improve efficiency

- Reasonably arrange cutting sequence to avoid workpiece deformation

- Adopt shortest path principle

- Consider tool life and machining quality

5.4 Quality Control System

- First article inspection: Comprehensive inspection of all dimensions

- Process inspection: 10-20% sampling by batch

- Last article inspection: Comparison with first article to confirm stability

- Establish control charts to monitor dimensional change trends

- Calculate process capability indices Cp, Cpk

- Take immediate corrective actions when Cpk<1.33

- Daily inspection: Lubricant level, air pressure, coolant

- Weekly inspection: Tool wear, fixture precision

- Monthly inspection: Machine precision, lubrication system

- Annual inspection: Comprehensive precision calibration, component replacement

6. Common Precision Problem Solutions

6.1 Dimensional Precision Deviation

- Severe tool wear

- Machine precision degradation

- Temperature change effects

- Timely tool replacement, establish tool life management

- Optimize cutting parameters to reduce cutting forces

- Regular machine precision calibration

- Improve workshop environmental temperature control

6.2 Surface Roughness Exceeding Standards

- Low cutting speed

- Excessive feed rate

- Insufficient coolant

- Select appropriate tool rake and clearance angles

- Increase cutting speed, adopt high-speed machining

- Reduce feed rate, increase number of passes

- Optimize coolant type and supply method

6.3 Geometric Tolerance Deviation

- Flatness deviation

- Cylindricity deviation

- Concentricity deviation

- Parallelism deviation

- Check machine geometric accuracy and perform error compensation

- Optimize fixture design to improve clamping rigidity

- Reasonably arrange machining sequence to reduce deformation

- Adopt step-by-step machining to control cumulative errors

6.4 Balancing Machining Efficiency and Precision

- Adopt high-speed machining technology to balance efficiency and quality

- Reasonably arrange processes to reduce clamping times

- Utilize automation technology to improve consistency

- IT5 grade precision costs 3-5 times that of IT8 grade

- Every precision grade improvement increases costs by approximately 40%

Disclaimer

- All information, opinions, and data contained in this article are for the purpose of information transmission only and do not constitute any advice on investment, transactions, law, medical care, or other matters.

- The content of the article is compiled based on public information or created based on the author’s personal understanding. Although every effort is made to ensure accuracy, it does not guarantee the completeness, accuracy, and timeliness of the information, nor does it bear any responsibility for any losses caused by the use of the content of this article.

- If the article involves third-party opinions, pictures, data, and other content, the copyright belongs to the original author. In case of infringement, please contact us for deletion.

- Readers should make independent decisions based on their actual situation and combined with professional opinions. The user shall bear all consequences arising from the use of the content of this article.