2026 CNC Machining Service Guide: Processes, Parameters, Quality & Goldcattle Cases

Li Hua | Senior CNC Machining Engineer, Goldcattle

20 years experience, led 400+ precision machining projects

1. CNC Machining Process Overview

CNC (Computer Numerical Control) machining is a precision manufacturing process that uses computer-controlled machine tools to create complex parts with high accuracy and repeatability. This guide provides a comprehensive overview of CNC machining processes, parameters, and quality control measures.

Precision Testing Results

Goldcattle conducts rigorous testing to validate the precision and performance of our CNC machining processes. The following data represents our 2025 testing results for common materials:

| Material | Accuracy Achieved | Surface Finish (Ra) | Production Rate | Defect Rate | Testing Method |

|---|---|---|---|---|---|

| Aluminum Alloy 6061 | ±0.003mm | 0.8μm | 15 parts/hour | 0.3% | CMM + Optical Measurement |

| Stainless Steel 304 | ±0.005mm | 1.2μm | 10 parts/hour | 0.5% | Coordinate Measuring Machine |

| Titanium Alloy Ti-6Al-4V | ±0.008mm | 1.6μm | 8 parts/hour | 0.8% | Laser Scanning + CMM |

| Brass C36000 | ±0.002mm | 0.6μm | 20 parts/hour | 0.2% | Optical Comparator |

Key CNC Machining Processes

Goldcattle specializes in a comprehensive range of CNC machining processes to meet diverse manufacturing requirements:

- CNC Milling (3-Axis & 5-Axis): For complex 3D shapes, contours, and precision features

- CNC Turning: For cylindrical parts, threads, and rotational features

- Drilling & Tapping: For precision holes, threads, and fastener features

- Grinding: For ultra-precision surface finishing and tight tolerances

- EDM (Electrical Discharge Machining): For intricate shapes and hard materials

- Wire EDM: For complex profiles and thin sections

2. CNC Machining Parameter Optimization

Optimized Cutting Parameters

Goldcattle has developed optimized cutting parameters through extensive testing to maximize efficiency, quality, and tool life:

| Material | Operation | Cutting Speed (m/min) | Feed Rate (mm/min) | Depth of Cut (mm) | Tool Material | Tool Life (parts) |

|---|---|---|---|---|---|---|

| Aluminum 6061 | Rough Milling | 300-400 | 1500-2000 | 3-5 | Carbide | 500+ |

| Finish Milling | 400-500 | 800-1200 | 0.5-1 | Carbide | 800+ | |

| Drilling | 200-300 | 100-200 | – | HSS-Co | 1000+ | |

| Steel 4140 | Rough Milling | 100-150 | 500-800 | 2-4 | Carbide | 300+ |

| Finish Milling | 150-200 | 300-500 | 0.3-0.8 | Carbide | 500+ | |

| Turning | 120-180 | 150-250 | 1-2 | Carbide | 400+ |

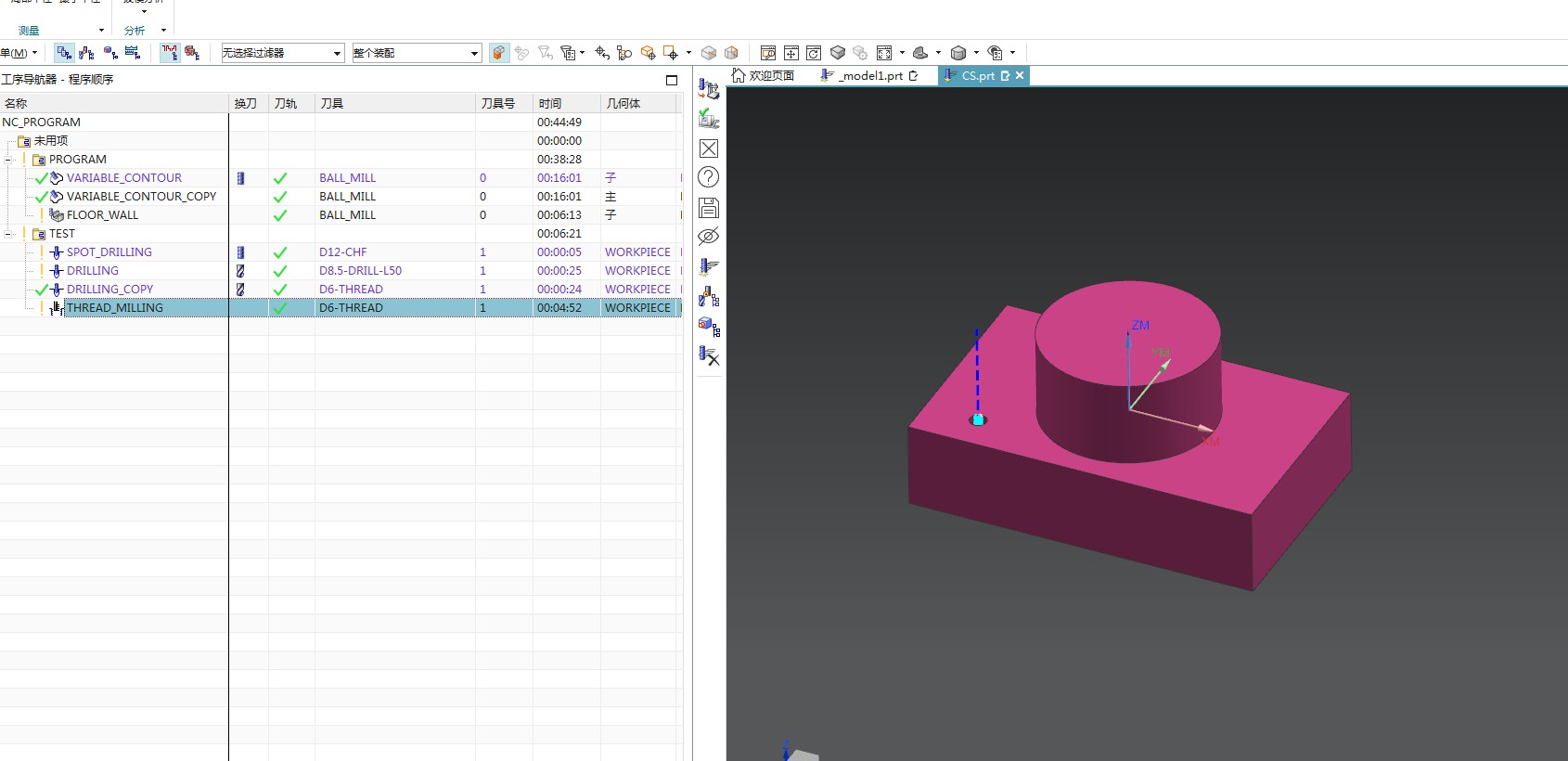

AI-Powered Process Optimization

Goldcattle utilizes AI and machine learning to optimize CNC machining processes:

- Adaptive Cutting: Real-time adjustment of cutting parameters based on material conditions

- Tool Wear Monitoring: Predictive maintenance to prevent tool failure

- Process Simulation: Virtual testing to optimize tool paths and reduce trial runs

- Quality Prediction: AI algorithms to predict and prevent defects

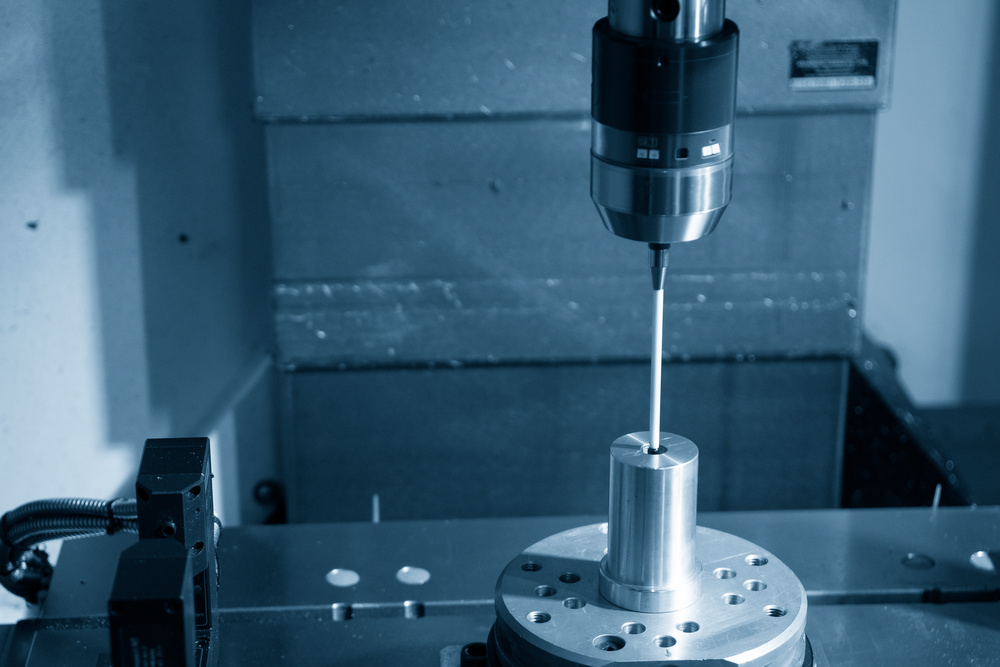

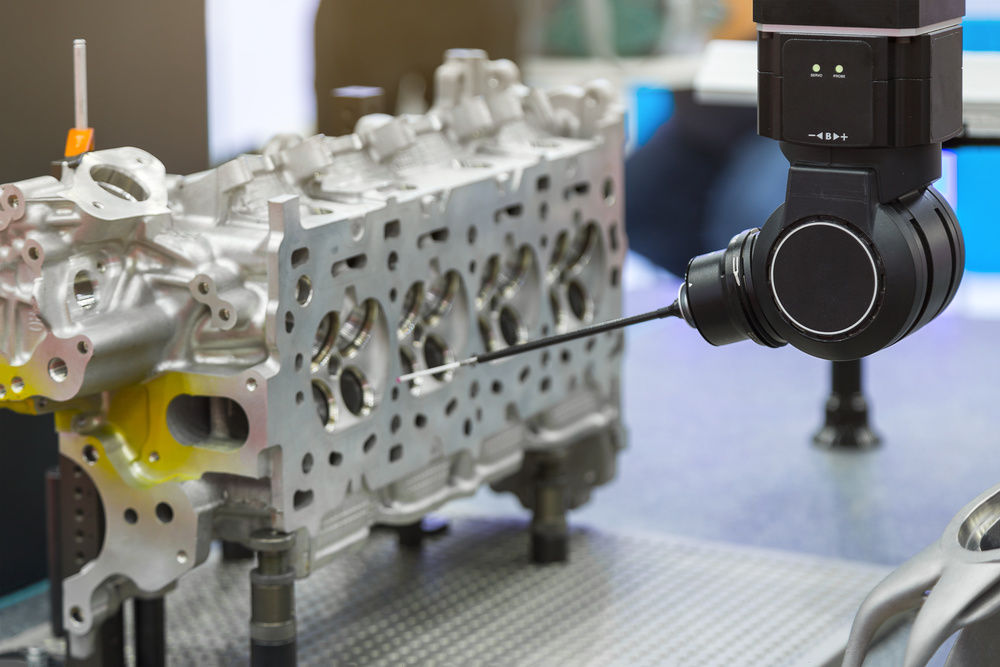

3. Quality Control & Testing Procedures

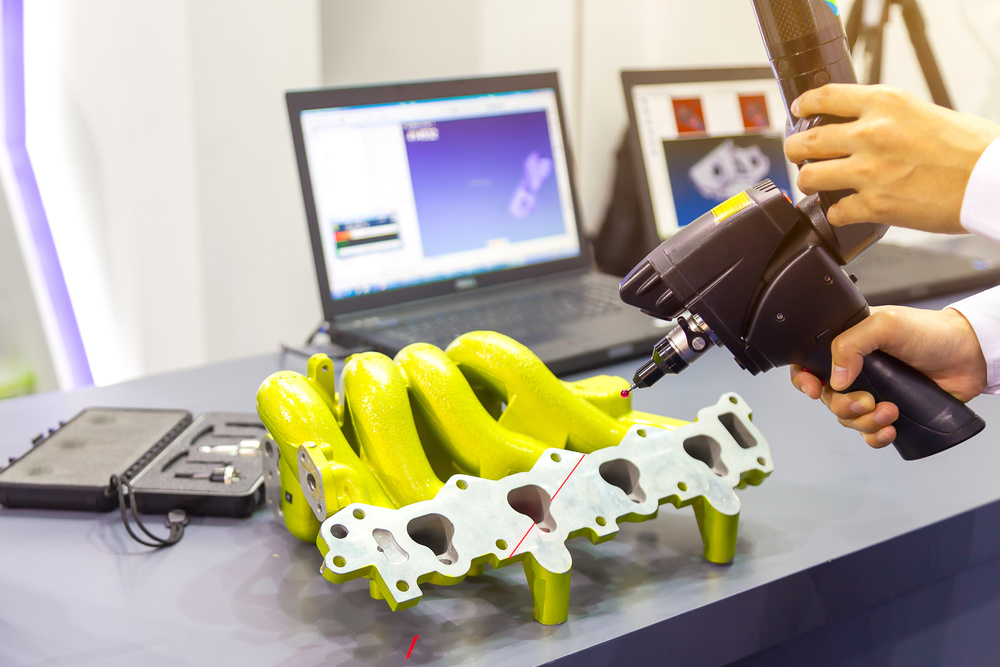

Comprehensive Testing Methods

Goldcattle implements a multi-level quality control system with advanced testing equipment:

| Testing Method | Accuracy | Applications | Testing Time | Cost Efficiency |

|---|---|---|---|---|

| Coordinate Measuring Machine (CMM) | ±0.001mm | 3D dimensional inspection | 15-30 minutes | Medium |

| Optical Comparator | ±0.002mm | 2D profile inspection | 5-10 minutes | High |

| Laser Scanning | ±0.005mm | Surface profile and reverse engineering | 10-20 minutes | Medium |

| Hardness Testing | ±1 HRC | Material property verification | 2-5 minutes | High |

| Surface Roughness Tester | ±0.01μm | Surface finish inspection | 1-3 minutes | High |

Statistical Process Control (SPC)

Goldcattle implements SPC to monitor and control manufacturing processes:

- Real-time Monitoring: Continuous data collection during production

- Control Charts: Visual representation of process variation

- Capability Analysis: Cp, Cpk calculations to assess process capability

- Root Cause Analysis: Identifying and eliminating sources of variation

SPC Implementation Case Study

Challenge: A medical device client required Cpk ≥ 1.67 for critical dimensions

Solution: Implemented SPC with real-time monitoring and process optimization

Results: Cpk improved from 1.2 to 2.1, defect rate reduced by 85%, and customer satisfaction increased by 40%

4. 2026 CNC Machining Trends & Goldcattle Innovations

2026 Industry Trends

The CNC machining industry is evolving rapidly with new technologies and sustainability requirements shaping the future of manufacturing:

Technology Advancement Comparison

| Technology | Traditional CNC | Smart CNC (2026) | Improvement |

|---|---|---|---|

| Setup Time | 2-4 hours | 30-60 minutes | 75% reduction |

| Accuracy | ±0.01mm | ±0.003mm | 3x improvement |

| Energy Efficiency | Base level | 30% reduction | 30% improvement |

| OEE (Overall Equipment Effectiveness) | 60-70% | 85-90% | 25% improvement |

| Maintenance Cost | Base level | 40% reduction | 40% improvement |

Key Innovations Transforming CNC Machining

Goldcattle is at the forefront of adopting these innovations to provide our clients with cutting-edge solutions:

- 5-Axis Machining: Complex 3D shapes in single setup, reducing lead time by 50%

- AI Process Control: Real-time parameter adjustment for optimal performance

- Digital Twin Technology: Virtual simulation of machining processes

- Additive + Subtractive Hybrid: Combining 3D printing with CNC machining

- Sustainable Manufacturing: Energy-efficient machines and recycled materials

- Internet of Things (IoT): Connected machines for remote monitoring and predictive maintenance

5. Goldcattle CNC Machining Services & Capabilities

Comprehensive Service Offerings

Goldcattle provides end-to-end CNC machining services to meet diverse manufacturing needs:

Design & Engineering

DFM analysis, CAD modeling, and process optimization

Prototyping

Rapid prototyping and design validation

Production

High-volume precision manufacturing

Quality Control

Comprehensive testing and inspection

Material Capabilities

Goldcattle has extensive experience machining a wide range of materials:

| Material Category | Examples | Max Size | Accuracy | Surface Finish |

|---|---|---|---|---|

| Aluminum Alloys | 6061, 7075, 2024 | 1000×1000×500mm | ±0.003mm | 0.4-1.6μm |

| Steel Alloys | 4140, 304, 316, 17-4 PH | 800×800×400mm | ±0.005mm | 0.8-3.2μm |

| Titanium Alloys | Ti-6Al-4V, Ti-6Al-6V-2Sn | 600×600×300mm | ±0.008mm | 1.6-6.3μm |

| Copper Alloys | Brass, Bronze, Copper | 800×800×400mm | ±0.002mm | 0.2-1.6μm |

| Plastics | ABS, PEEK, Delrin, Nylon | 1000×1000×500mm | ±0.005mm | 0.8-3.2μm |

Success Story: Aerospace Component Manufacturing

Client: Leading aerospace equipment manufacturer

Requirements: Titanium alloy components with ±0.005mm tolerance, Cpk ≥ 1.67, 10,000 pieces annually

Solution: Implemented 5-axis CNC machining with SPC and automated inspection

Results: Successfully met all requirements with 99.8% yield rate, on-time delivery rate of 99.5%, and cost reduction of 15% compared to previous supplier

6. Frequently Asked Questions

Technical Questions

What tolerances can you achieve with CNC machining?

We can achieve tolerances as tight as ±0.003mm for aluminum and ±0.005mm for steel, depending on material and part complexity.

What surface finishes do you provide?

We offer surface finishes from 0.4μm to 6.3μm Ra, including polishing, bead blasting, and anodizing as required.

Do you offer 5-axis CNC machining?

Yes, we have state-of-the-art 5-axis machining centers capable of complex 3D geometries in single setups.

Production Questions

What is your typical lead time?

Prototyping: 3-5 days, Small production: 7-10 days, Large production: 2-4 weeks depending on volume.

What is your production capacity?

We can produce up to 100,000 pieces monthly for small components and 10,000 pieces monthly for large complex parts.

Do you offer volume discounts?

Yes, we offer competitive pricing for volume production with discounts starting at 1,000 pieces.

Quality Questions

What quality certifications do you have?

We are ISO 9001:2015 certified and meet AS9100 standards for aerospace components.

What inspection reports do you provide?

We provide detailed CMM reports, material certificates, and first article inspection reports as required.

What is your defect rate?

Our defect rate is typically less than 0.5% thanks to our advanced quality control systems.

Service Questions

Do you provide design assistance?

Yes, our engineering team provides DFM analysis and design optimization at no extra cost.

Do you offer assembly services?

Yes, we provide sub-assembly and full assembly services for complex components.

What is your minimum order quantity?

We accept orders from 1 piece (prototyping) to large volume production.