In the ever – evolving landscape of modern manufacturing, CNC machining turning parts have emerged as a cornerstone for producing high – precision rotational components. Leveraging the power of Computer Numerical Control (CNC) technology, turning operations can create parts with exceptional accuracy, repeatability, and efficiency, meeting the stringent demands of industries ranging from aerospace and automotive to medical and electronics. This article delves into the technical capabilities, customization process, material selection, quality control, and industry applications of CNC machining turning parts, highlighting their significance in driving innovation and reliability across various sectors.

I. Technical Capabilities: Unrivaled Precision in Rotational Machining

(A) Ultra – High Dimensional Accuracy

CNC turning machines are meticulously calibrated to achieve extraordinary dimensional precision in part production. With positioning accuracy reaching ±0.002mm and repeat positioning accuracy of ±0.003mm, we can fabricate turning parts with extremely tight tolerances. For example, when manufacturing shafts for high – precision industrial machinery, the diameters of the shaft segments, the lengths of the stepped sections, and the accuracy of the threaded portions can all be maintained within these precise limits. This level of accuracy ensures a perfect fit between components, minimizing clearances and enhancing the overall performance and reliability of the assembled systems.

(B) Complex Shape Machining

CNC turning technology, especially when combined with live tooling and multi – axis capabilities, enables the machining of parts with complex shapes. From parts with intricate contours, such as camshafts with variable lobe profiles, to components with internal geometries like stepped bores and tapered holes, CNC turning can execute these designs with ease. Compared to traditional turning methods, CNC turning reduces setup – related errors from ±0.01mm to within ±0.003mm. Moreover, it boosts production efficiency by over 60% through automated tool changes and optimized machining paths, allowing for the rapid manufacturing of complex turning parts even with the most challenging designs.

(C) Advanced Machining Techniques

To meet the diverse requirements of different materials and applications, we employ a range of advanced machining techniques in CNC turning. For hard materials like titanium alloys and hardened steels, high – speed machining with specialized carbide tools and optimized cutting parameters is used to reduce tool wear and maintain surface integrity. In the case of soft materials such as aluminum alloys and plastics, precision finishing techniques like diamond turning can be applied to achieve a mirror – like surface finish. Additionally, processes like threading, grooving, and facing can be carried out with high precision, ensuring that every aspect of the turning part meets the highest quality standards.

II. End – to – End Customization: Tailored Solutions for Your Needs

(A) In – Depth Requirement Analysis and Design Conceptualization

When you approach us with your CNC turning part requirements, our experienced engineering team initiates detailed discussions to understand your application, performance expectations, and design preferences. We consider factors such as the operating environment (temperature, humidity, corrosive conditions), the mechanical loads the part will endure, and any specific functional or aesthetic requirements. Using state – of – the – art CAD/CAM software, we generate multiple design concepts. We then collaborate closely with you, refining the designs based on your feedback until they perfectly align with your vision, whether it’s a minor modification to a standard part or a completely new design for a specialized project. For instance, if you need a custom – made shaft for a high – torque transmission system, we will analyze the torque requirements, rotational speeds, and environmental factors to create a design that optimizes the part’s performance.

(B) Strategic Material Selection and Cost Analysis

Based on the finalized design, we recommend the most suitable materials for your turning parts. Different materials offer varying combinations of strength, durability, machinability, and cost. For applications requiring high strength and wear resistance, materials like alloy steels and tool steels are often preferred. In contrast, for lightweight and corrosion – resistant applications, aluminum alloys and stainless steels are excellent options. Simultaneously, we conduct a detailed cost analysis, factoring in material costs, machining complexity, the need for custom tooling, and production volume, to provide you with a transparent and competitive quote. Our goal is to help you select the material that offers the best balance of performance and cost for your specific application.

(C) Precision Manufacturing and Order Tracking

Once you approve the design and quote, production commences. You can monitor the progress of your order in real – time through our dedicated online tracking platform. Our skilled technicians operate state – of – the – art CNC turning machines, following strict manufacturing standards to produce parts that meet the highest quality benchmarks. We keep you informed at every stage of the production process, from raw material procurement to the final inspection, ensuring complete transparency and peace of mind throughout the manufacturing journey. Whether your order is for a single prototype or a large – scale production run, we are committed to delivering your turning parts on time and to the highest quality standards.

(D) Rigorous Quality Assurance and Timely Delivery

After production, each CNC turning part undergoes a rigorous quality inspection. Only parts that meet our exacting standards are shipped to you. We perform dimensional inspections using coordinate measuring machines (CMMs) to ensure that all critical dimensions are within ±0.002mm. Surface finish measurements are taken to ensure that the surface meets the required roughness specifications for optimal functionality and aesthetics. In addition, we conduct mechanical tests, such as tensile strength testing, fatigue testing, and hardness testing, to validate the performance of the parts. Non – destructive testing methods, such as ultrasonic testing and dye penetrant inspection, are used to detect any internal or surface – breaking defects. We also offer comprehensive after – sales support, addressing any concerns you may have during the product’s lifecycle, and ensuring timely delivery to minimize downtime for your operations.

III. Strategic Material Selection: Matching Materials to Performance Requirements

(A) Alloy Steels

Alloy steels are widely used in CNC turning parts due to their high strength, toughness, and wear resistance. They contain alloying elements such as chromium, nickel, molybdenum, and vanadium, which enhance their mechanical properties. For example, 4140 alloy steel, with its good combination of strength and hardenability, is commonly used for parts like shafts, axles, and gears in industrial machinery and automotive applications. Its ability to withstand high torque and bending forces makes it a reliable choice for components that are subject to heavy loads and dynamic stresses.

(B) Aluminum Alloys

Aluminum alloys are highly valued for their lightweight properties, excellent formability, and good corrosion resistance. Alloys such as 6061 – T6 and 7075 – T6 are commonly used in aerospace, automotive, and electronics industries. 6061 – T6 offers a good balance of strength, corrosion resistance, and machinability, making it suitable for a variety of applications, from structural components to consumer products. 7075 – T6, on the other hand, is a high – strength alloy often used in applications where maximum strength – to – weight ratio is required, such as in aircraft structures and high – performance automotive parts. In CNC turning, aluminum alloys can be machined quickly and accurately, allowing for the production of lightweight yet strong components.

(C) Stainless Steels

Stainless steels are preferred for applications where corrosion resistance is crucial. They contain chromium, which forms a passive oxide layer on the surface, protecting the material from rust and chemical attack. 304 stainless steel, with its good corrosion resistance and formability, is suitable for a wide range of applications, including food processing equipment, medical devices, and general industrial components. For more aggressive environments, 316 stainless steel, which contains molybdenum for enhanced corrosion resistance, is often the material of choice. CNC turning of stainless steel parts requires specialized tools and machining strategies to prevent work – hardening and ensure a smooth surface finish.

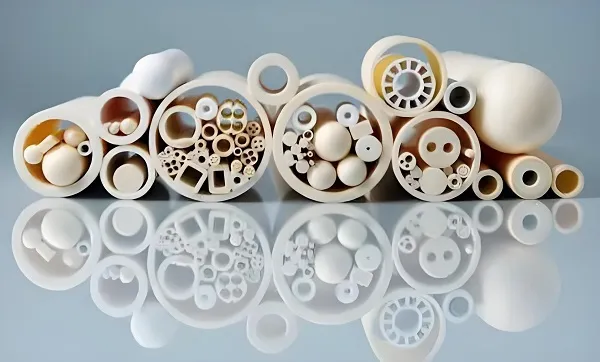

(D) Plastics and Composites

In some cases, plastics and composite materials are used for CNC turning parts. Plastics offer advantages such as low cost, lightweight, and good electrical insulation properties. Engineering plastics like ABS, nylon, and PEEK are commonly used for parts in the electronics, consumer goods, and medical industries. PEEK, in particular, is known for its high – temperature resistance, chemical inertness, and excellent mechanical strength, making it suitable for demanding applications. Composites, which combine the benefits of different materials, can also be turned on CNC machines to produce parts with high strength – to – weight ratios and specific performance characteristics, such as those used in aerospace and sports equipment.

IV. Stringent Quality Control: Ensuring Excellence in Every Part

(A) Raw Material Inspection

All incoming raw materials for CNC turning parts are subject to strict quality checks. We use spectroscopic analysis to verify the chemical composition of the materials, ensuring that they meet the required standards. Additionally, hardness testing, tensile testing, and microstructure analysis are performed to ensure the material’s integrity and suitability for the intended application. For example, when using alloy steel, we confirm that the alloying element ratios and mechanical properties meet the specified requirements. Only high – quality materials that pass these rigorous inspections are used in the production of our turning parts.

(B) In – Process Monitoring

Throughout the manufacturing process, we employ statistical process control (SPC) techniques to monitor key manufacturing parameters. Regular sampling and data collection help us identify and correct any potential issues promptly. We monitor parameters such as cutting speeds, feed rates, tool wear, and the temperature during turning operations. If any parameter deviates from the set values, we can adjust the process in real – time to ensure consistent product quality, maintaining the precision and reliability of each turning part. This proactive approach to quality control helps us prevent defects and ensure that every part meets our high – quality standards.

(C) Final Product Validation

Before shipping, each CNC turning part undergoes a comprehensive inspection. We use CMMs to verify dimensional accuracy, ensuring that all critical dimensions are within ±0.002mm. Surface roughness measurements are taken to ensure that the surface finish is optimized for the part’s intended function. Non – destructive testing methods, such as ultrasonic testing and magnetic particle inspection, are used to detect any internal or surface – breaking defects. Only parts that pass all these tests are considered ready for delivery. Our commitment to quality control ensures that you receive turning parts that are reliable, durable, and perform to your expectations.

V. Diverse Industry Applications: Meeting the Demands of Every Sector

(A) Aerospace Industry

In the aerospace industry, the demand for high – precision, lightweight, and reliable components is extremely high. CNC turning parts play a crucial role in the construction of aircraft and spacecraft. From engine components such as turbine shafts, compressor disks, and fan blades, to structural parts like landing gear components and wing struts, our precision – machined turning parts are manufactured with the highest level of precision using advanced materials and machining techniques. The use of lightweight materials such as titanium alloys and aluminum alloys, combined with the precision of CNC turning, helps reduce the weight of aerospace vehicles, improving fuel efficiency and performance while ensuring safety and reliability.

(B) Automotive Industry

The automotive industry relies on CNC turning parts to improve the performance, efficiency, and durability of vehicles. Custom – made components such as engine crankshafts, camshafts, transmission shafts, and axles are essential for optimizing engine performance, reducing noise and vibration, and enhancing vehicle handling. Our CNC turning parts are designed and manufactured to meet the strict requirements of the automotive industry, using materials that offer a balance of strength, weight, and cost. The use of advanced machining techniques ensures that these parts fit perfectly within the vehicle’s assembly, improving overall performance and reliability.

(C) Medical Industry

In the medical field, the safety and precision of components are of utmost importance. CNC turning parts are used in a variety of medical applications, including surgical instruments, medical implants, and diagnostic equipment. Surgical instruments such as drill bits, reamers, and cannulas require high precision and sharpness to ensure accurate and safe procedures. Medical implants, such as orthopedic implants and dental prosthetics, need to be precisely shaped to fit the patient’s anatomy and provide long – term functionality. Our CNC turning parts are manufactured using biocompatible materials and strict quality control measures to ensure the safety and effectiveness of medical devices, helping to improve patient outcomes.

(D) Electronics Industry

In the electronics industry, where miniaturization and precision are key, CNC turning parts are used for a variety of applications, including heat sinks, connectors, and housings. Heat sinks made from aluminum alloys or copper are precisely turned to maximize heat dissipation, ensuring the proper functioning of electronic components. Connectors and housings, which require precise dimensions and smooth surfaces for reliable electrical connections and protection, are also manufactured using CNC turning. The ability to machine small – diameter parts with high precision makes CNC turning an ideal process for producing components in the electronics industry.

VI. Frequently Asked Questions (FAQ)

(A) What is the typical precision of CNC machining turning parts?

Our CNC turning can achieve a dimensional tolerance of ±0.002mm, ensuring a precise fit and optimal performance in various applications. This level of precision allows us to manufacture parts that meet the most demanding requirements of different industries.

(B) How long does it take to produce custom turning parts?

Lead times vary depending on the complexity of the design, the materials used, and the order quantity. Simple designs can be completed in 3 – 5 days, while more complex ones may take 7 – 10 days. Rush orders are available upon request to meet urgent deadlines. We strive to provide fast turnaround times without compromising on quality.

(C) Can you customize turning parts according to my specific design?

Yes, our team of experts can work closely with you to understand your design requirements and create custom turning parts that meet your exact specifications. We use advanced CAD/CAM software and CNC turning technology to bring your designs to life, whether they are simple modifications or complex, unique designs.

(D) What types of materials can be used for CNC turning parts?

We can work with a wide range of materials, including metals (such as alloy steels, aluminum alloys, stainless steels, and titanium alloys), engineering plastics, and some composite materials. Our engineers will recommend the most suitable material based on your application requirements, performance goals, and budget.

(E) How do you ensure the quality of CNC turning parts?

We have a comprehensive quality control system in place, including raw material inspection, in – process monitoring, and final product validation. All parts are inspected using advanced measuring equipment and undergo various mechanical tests to ensure they meet our high – quality standards. Our ISO – certified quality management system ensures that every aspect of the manufacturing process is carefully controlled to deliver parts that are reliable and of the highest quality.

VII. Customer Testimonials

An aerospace company approached us to develop custom titanium alloy turbine shafts for their new aircraft engine. Our team utilized advanced CNC turning and material selection techniques to create shafts that met the strict aerospace standards. The new shafts not only reduced the weight of the engine by 18% but also improved its overall efficiency and reliability. The company was highly satisfied with the quality and performance of our custom turning parts, leading to a long – term partnership.

A medical device manufacturer needed custom – designed stainless steel orthopedic implants. We designed and manufactured the implants using precision CNC turning, ensuring precise dimensions and a smooth surface finish. The custom implants met the strict requirements of the medical industry, providing the manufacturer with a competitive edge in the market. The company praised our attention to detail and the excellent quality of the parts, which helped them gain customer trust and increase sales.

Reach Out Now for Your CNC Machining Turning Parts!

Whether you are in the aerospace, automotive, medical, electronics, or any other industry, our team of experts is ready to provide you with high – quality, customized CNC machining turning parts. We offer a seamless end – to – end service, from design and material selection to manufacturing and quality assurance. Contact us today to discuss your project requirements and take the first step towards getting parts that will enhance the performance and innovation of your products.