In an era of pursuing precision and customization, CNC (Computer Numerical Control) technology has long broken through the boundaries of metal processing. With its unparalleled precision and flexibility, it has demonstrated revolutionary power in the field of wooden parts manufacturing. Whether it is a classic furniture component with a century – old heritage or a modern decorative element with innovative design, CNC turning technology, like a sharp “digital carving knife”, is perfectly integrating the natural beauty of wood with engineering precision, opening a new chapter in woodcraft manufacturing.

Core Advantages: When Wood Meets Precision CNC Turning

Master of Material Handling: Beyond Hardwoods

Wide Adaptability: CNC turning can efficiently process a variety of woods, from low – density pine and basswood (common spindle speeds: 2000 – 3500 RPM, feed rates: 0.15 – 0.3 mm/rev) to extremely hard red sandalwood and black walnut (speeds may drop to 800 – 1800 RPM, feed rates: 0.05 – 0.15 mm/rev). Even for woods with complex textures or internal knots, modern CNC systems can stably handle them through intelligent path planning and tool selection (such as diamond – coated carbide tools).

Moisture Content Control: The unique “breathing” property of wood requires strict moisture content control (usually stabilized at 6% – 10%). After precision CNC processing, combined with scientific seasoning or secondary drying processes, the risk of deformation and cracking of the finished product can be greatly reduced, ensuring dimensional stability.

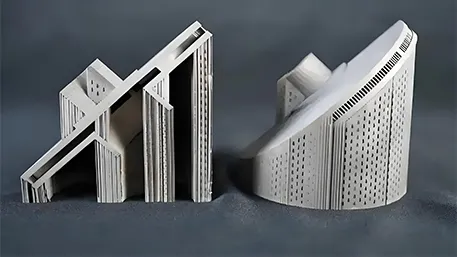

Sculptor of Complex Geometric Shapes: Beyond Traditional Lathes

Free – form Surfaces and Special – shaped Parts: CNC turning centers (especially turning – milling composite models with Y – axis or C – axis) can easily achieve non – circular cross – sections, eccentric contours, and complex reliefs (such as Baroque – style column capitals, multi – curved musical instrument parts). With a single clamping, multiple composite processes such as turning the outer circle, facing, drilling, milling grooves, and carving textures can be completed, far exceeding the efficiency and precision of traditional multi – process operations.

Micro – feature Machining: Precision tools (such as small – radius circular arc tools, V – shaped carving tools), combined with high – rigidity spindles (run – out accuracy < 0.01mm) and high – resolution encoders, can machine clear grooves, sharp edges, fine knurling (depth accuracy up to ±0.05mm), or subtle texture changes.

The Cornerstone of Precision and Consistency: Digital Assurance

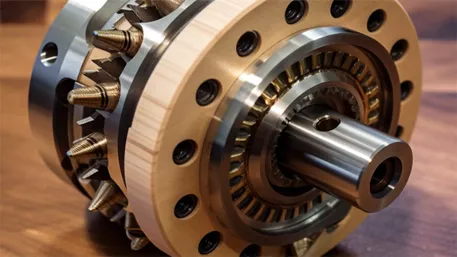

Micron – level Reproducibility: Modern CNC systems have a positioning accuracy of up to ±0.005mm and a repeat positioning accuracy of ±0.002mm. This means that whether producing 1 piece or 1000 pieces, the key dimensions (such as the bearing – fitting hole φ20H7 tolerance zone) and key geometric tolerances (such as cylindricity of 0.03mm) of each wooden part can be strictly guaranteed.

Digital Process Chain: From 3D model (CAD) to tool – path planning (CAM) and then to machine execution (G – code), the entire process is digital, eliminating human errors. Strict tool wear monitoring (usually changing the tool every X hours of machining or after monitoring changes in cutting force) and automatic compensation mechanisms are the core guarantees of continuous precision.

Efficiency Revolution: A Win – win for Mass Production and Quick Response

High – Speed Cutting (HSC) Application: On the premise of ensuring that the wood does not burn (controlling the cutting temperature), for suitable woods, a strategy of high – speed rotation (such as over 5000 RPM) and high – feed (over 0.4 mm/rev) is adopted. Combined with an optimized layer – by – layer cutting strategy (such as trochoidal milling for roughing), the single – piece processing time can be significantly shortened.

Automation Integration: Combined with automatic feeding machines and robotic loading and unloading systems, the CNC turning unit can achieve 24 – hour continuous production, greatly increasing production capacity, especially suitable for mass – produced standard parts (such as wooden buttons, furniture tenons).

Surface Finish: Dual Pursuit of Touch and Aesthetics

“Mirror – like” Effect: Through precise finishing turning processes (using tools with sharp edges and a very small tool – tip arc radius of R0.2), optimized cutting parameters (low feed, high speed), and vibration control technology, an ultra – smooth surface with Ra < 1.6 μm can be directly obtained on the machine tool, significantly reducing the subsequent polishing workload.

Special Texture Effects: CNC can not only achieve a smooth surface but also precisely control the tool path through programming to create unique decorative textures such as spiral patterns, cross – hatched lines, and regular concave – convex dot matrices, adding personality to the design.

From Idea to Reality: Typical Applications of CNC – turned Wooden Parts

High – end Furniture and Architectural Decoration: Precise turned table legs, staircase columns, carved panels, and special – shaped handrails.

Musical Instrument Manufacturing: Woodwind instrument keys, guitar necks, and violin pegs with extremely high pitch accuracy requirements, where the fitting accuracy directly affects the timbre.

Cultural and Creative Products and Gifts: Complex geometric – shaped pen holders, exquisite chess components, and art ornaments.

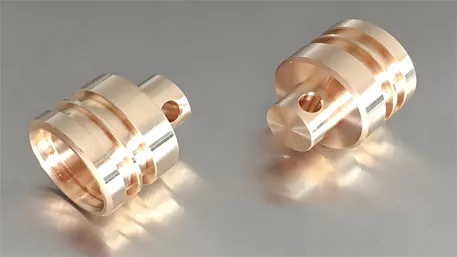

Functional Components: Wear – resistant bearing sleeves, wooden brackets for precision instruments, and customized tool handles.

Wooden Mortise – and – Tenon Connectors: High – precision and highly consistent round tenons and special – shaped tenons ensure assembly strength and a perfect fit.

Customize Your Woodcraft Masterpiece: Let Precision CNC Unleash Infinite Possibilities

Wood carries the warmth of nature and the flavor of humanity. CNC turning technology injects the precise soul of modern engineering into this warmth and flavor. Whether the design drawing in your hand depicts classic inheritance or avant – garde innovation, whether your needs are small – batch trial production or large – scale production, relying on advanced multi – axis CNC turning centers (such as turning – milling composite equipment equipped with a powered turret, Y – axis, and B – axis), profound expertise in wood processing (covering a database of hundreds of wood properties), and a persistent pursuit of micron – level precision, we are committed to transforming your wooden part ideas into tangible and exquisite realities.

Are you facing challenges with your unique design?

Looking for a partner who can stably process high – difficulty special – shaped wooden components?

Need a large number of highly consistent wooden functional parts?

Pursuing ultimate surface finish or special decorative textures?

Contact our CNC wood – processing experts now! Provide your design drawings or conceptual requirements, and we will tailor the optimal processing plan for you, along with a detailed technical feasibility analysis and an accurate quotation. Click “Get Customized Solution” below or call [Your Phone Number], and let’s jointly carve your woodcraft legend.

Precision is not limited to metals. In the warp and weft of wood, we use code as a carving knife and data as a ruler to endow natural materials with an industrial – grade perfect expression.