In the world of international trade and manufacturing, the demand for high-quality plastic parts is on the rise. One of the most effective methods for producing these parts is through computer numerical control (CNC) milling.

CNC milling of plastic parts offers a level of precision and versatility that is hard to match with other manufacturing methods. This technology allows for the creation of complex shapes and designs with tight tolerances, making it ideal for a wide range of applications.

The Advantages of CNC Milled Plastic Parts

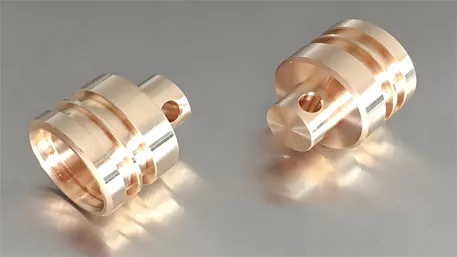

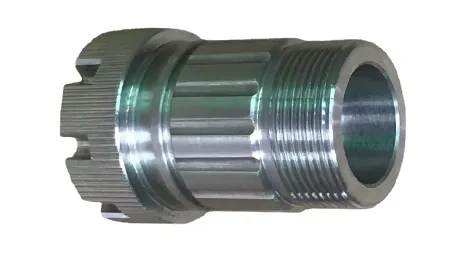

Precision: CNC milling machines are capable of producing plastic parts with extremely accurate dimensions and smooth surfaces. This level of precision is essential for applications where fit and function are critical, such as in the electronics, medical, and aerospace industries.

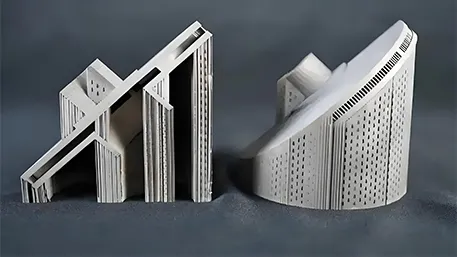

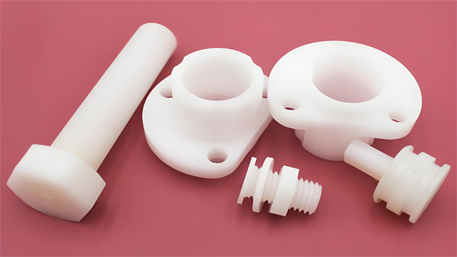

Versatility: Plastic is a highly versatile material that can be machined into a variety of shapes and sizes. With CNC milling, it is possible to create complex geometries and intricate designs that would be difficult or impossible to achieve with other manufacturing methods.

Material Options: There are many different types of plastic materials available for CNC milling, each with its own unique properties and characteristics. This allows manufacturers to choose the material that best suits their specific application requirements, whether it be for strength, durability, heat resistance, or chemical resistance.

Cost-Effective: Compared to other manufacturing methods, such as injection molding, CNC milling can be a cost-effective option for producing small to medium quantities of plastic parts. This is because it does not require expensive molds or tooling, and can be set up quickly for short production runs.

Quick Turnaround: CNC milling machines can produce plastic parts relatively quickly, especially compared to traditional manufacturing methods. This allows for shorter lead times and faster delivery of products, which is crucial in today’s fast-paced global marketplace.

Applications of CNC Milled Plastic Parts

Electronics: Plastic parts produced by CNC milling are widely used in the electronics industry. These parts can include enclosures, connectors, and insulators, which require precise dimensions and high-quality finishes.

Medical: In the medical field, CNC milled plastic parts are used for a variety of applications, such as surgical instruments, implants, and prosthetics. These parts must meet strict quality and safety standards, and CNC milling is able to provide the precision and reliability needed.

Aerospace: The aerospace industry also relies on CNC milled plastic parts for various components, such as ducting, brackets, and panels. These parts must be lightweight yet strong and durable, and plastic materials offer an ideal solution.

Automotive: Plastic parts produced by CNC milling are used in the automotive industry for applications such as interior trim, dashboard components, and engine parts. These parts must be able to withstand high temperatures and vibrations, and plastic materials can be engineered to meet these requirements.

Consumer Goods: From toys and household appliances to sporting goods and furniture, CNC milled plastic parts are found in a wide range of consumer products. These parts can add aesthetic appeal and functionality to products, while also being cost-effective to produce.

Choosing a Reliable CNC Milling Service Provider

When it comes to sourcing CNC milled plastic parts for your international business, it is important to choose a reliable and experienced service provider. Here are some factors to consider when making your selection:

Quality and Precision: Look for a service provider that has a reputation for producing high-quality plastic parts with tight tolerances. Ask for samples or references to ensure that their work meets your standards.

Material Selection: Make sure the service provider offers a wide range of plastic materials to choose from, and can recommend the best material for your specific application.

Technology and Equipment: Check that the service provider uses state-of-the-art CNC milling machines and software to ensure efficient and accurate production.

Experience and Expertise: Choose a service provider with extensive experience in CNC milling of plastic parts. Their expertise can help you optimize your designs and ensure a successful production run.

Customer Service: Good customer service is essential when working with a CNC milling service provider. Look for a company that is responsive to your inquiries, provides clear communication throughout the production process, and offers on-time delivery.

In conclusion, CNC milled plastic parts offer a level of precision, versatility, and cost-effectiveness that makes them an attractive option for international businesses. Whether you need parts for the electronics, medical, aerospace, automotive, or consumer goods industries, CNC milling can provide the quality and performance you require. By choosing a reliable service provider, you can ensure a successful production run and take your business to the next level.