1. Basic Principles: The Philosophy of Motion and Stillness

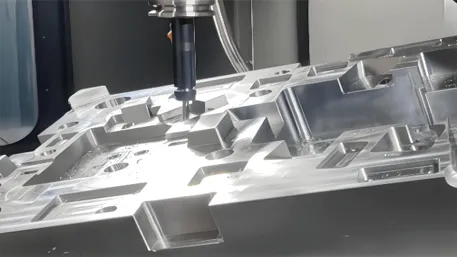

1.1 CNC Milling: Rotating Tool, Stationary Workpiece

- The workpiece is firmly fixed on the machine table

- The milling cutter rotates at high speed driven by the spindle (typically 8,000-40,000rpm)

- The tool can move in X, Y, and Z axes

- Complex milling machines can also achieve 4-axis or 5-axis simultaneous machining

- The desired part shape is formed through the movement trajectory of the tool

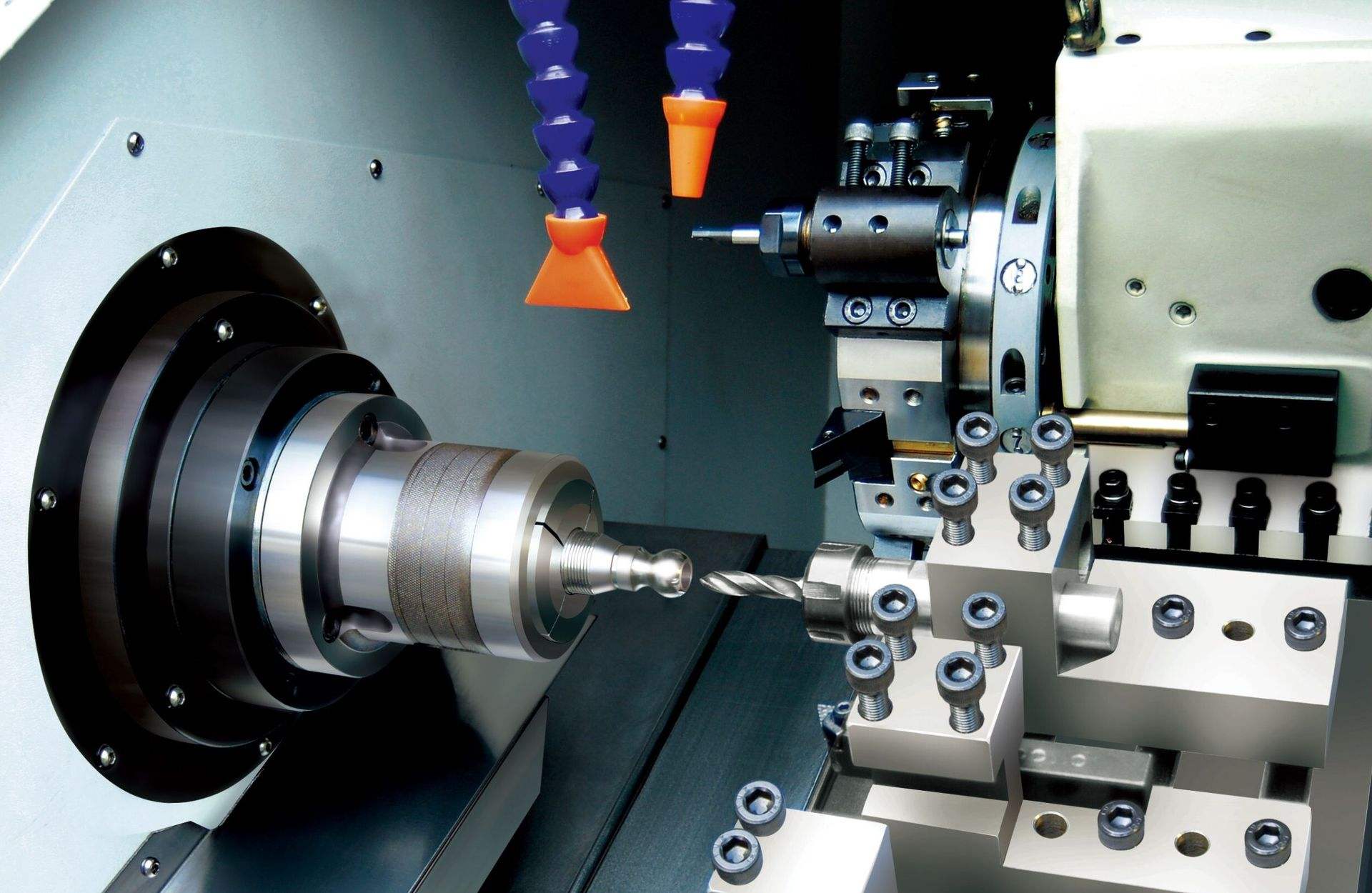

1.2 CNC Turning: Rotating Workpiece, Moving Tool

- The workpiece is clamped in the spindle chuck and rotates at high speed (typically 1,000-6,000rpm)

- The tool moves along the axial and radial directions of the workpiece

- Machining is mainly performed in X-axis and Z-axis directions

- Cutting depth is controlled by controlling the feed rate of the tool

- Particularly suitable for machining cylindrical or rotationally symmetric parts

2. Equipment and Technical Parameters Comparison: The Truth Behind the Numbers

2.1 Core Technical Parameters Comparison

|

Parameter

|

CNC Milling

|

CNC Turning

|

Difference Analysis

|

|

Number of Axes

|

3-5 axes

|

2 axes (standard)

|

Milling offers higher flexibility

|

|

Spindle Speed

|

8,000-40,000rpm

|

1,000-6,000rpm

|

Milling speed is significantly higher

|

|

Surface Roughness

|

Ra 0.4-1.6μm

|

Ra 0.8-3.2μm

|

Milling provides better surface quality

|

|

Machining Accuracy

|

±0.003-0.01mm

|

±0.005-0.02mm

|

Milling offers slightly higher precision

|

|

Feed Rate

|

20-60m/min

|

10-30m/min

|

Milling feeds faster

|

|

Tool Type

|

Multi-flute tool

|

Single-point tool

|

Milling tools are more efficient

|

2.2 Equipment Structure Characteristics

- Vertical or horizontal spindle layout

- Worktable can move in X and Y directions

- Spindle moves in Z direction

- Equipped with Automatic Tool Changer (ATC)

- 4/5-axis machines also equipped with rotary tables

- Horizontal spindle layout

- Workpiece clamped in spindle chuck

- Tools mounted on turret

- Turret can move in X and Z directions

- High-end models equipped with sub-spindle

3. Tool Systems: Different “Surgical Knives”

3.1 Milling Tools: Multi-flute Efficiency

- End Mills: Most commonly used, suitable for flat surfaces, steps, and groove machining

- Face Mills: Specifically for large area flat surface machining

- Ball Nose Mills: Suitable for curved surfaces and 3D contour machining

- T-slot Mills: Used for machining T-slots

- Dovetail Mills: Used for machining dovetail grooves

- High-Speed Steel (HSS): Suitable for low-speed cutting, lower cost

- Carbide: Suitable for high-speed cutting, good durability

- Ceramic Tools: Suitable for ultra-high speed cutting of hard materials

- Diamond Tools: Used for ultra-precision machining

3.2 Turning Tools: Single-point Precision

- External Turning Tools: Used for machining external surfaces of workpieces

- Internal Turning Tools: Used for machining internal holes and boring

- Facing Tools: Used for machining workpiece end faces

- Threading Tools: Used for machining internal and external threads

- Parting Tools: Used for cutting off workpieces or making grooves

- Rake Angle: Affects cutting force and chip flow direction

- Clearance Angle: Affects tool life and surface quality

- Lead Angle: Affects cutting force distribution and tool life

- Edge Angle: Affects chip evacuation direction

4. Application Scenario Analysis: Specialized Machining Fields

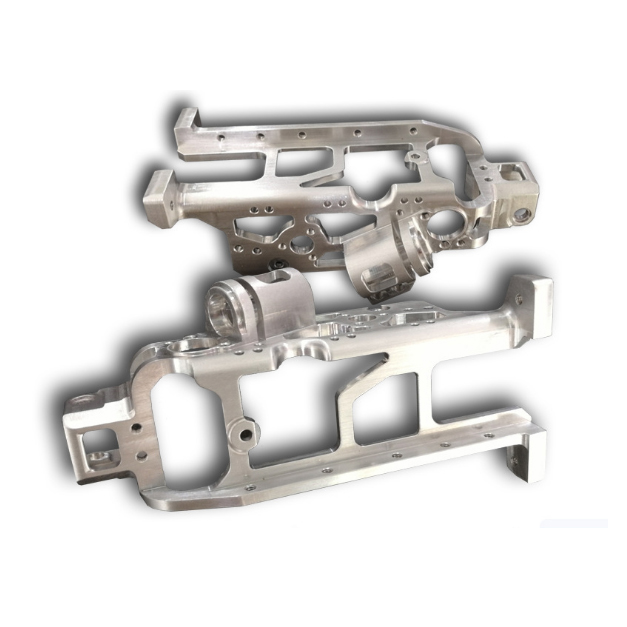

4.1 Advantageous Applications of CNC Milling

- Complex Cavity Machining

-

- Mold cores and cavities

-

- Precision jigs and fixtures

-

- Engine blocks

- Multi-face Machining Requirements

-

- Box-type parts

-

- Brackets and connectors

-

- Complex assemblies

- Fine Structure Manufacturing

-

- Precision gears and racks

-

- Micro-channels and micro-hole structures

-

- Thin-walled and complex curved surfaces

- Special Material Processing

-

- Carbon fiber composites

-

- High-temperature alloys

-

- Titanium alloys and other difficult-to-machine materials

4.2 Specialized Fields of CNC Turning

- Rotational Symmetric Parts

-

- Various shaft parts

-

- Discs and flanges

-

- Bearing housings and bushings

- Mass Production Requirements

-

- Standard fasteners

-

- Connectors and fittings

-

- High-volume standard parts

- High Surface Finish Requirements

-

- Mirror turning parts

-

- Optical components

-

- Sealing surfaces and mating surfaces

- Thin-walled and Slender Parts

-

- Hydraulic cylinders

-

- Sensor housings

-

- Slender shaft parts

5. Cost-Benefit Analysis: You Get What You Pay For

5.1 Machining Efficiency Comparison

|

Part Type

|

Milling Time

|

Turning Time

|

Efficiency Difference

|

|

Simple Cylinder

|

30 minutes

|

10 minutes

|

Turning 3x faster

|

|

Complex Shaped Part

|

20 minutes

|

Cannot machine

|

Milling only option

|

|

Mixed Feature Part

|

45 minutes

|

60 minutes

|

Milling 25% faster

|

|

Mass Production Part

|

5 minutes/piece

|

2 minutes/piece

|

Turning 60% faster

|

5.2 Equipment Investment Cost

- Economic 3-axis Milling Machine: ¥150,000-300,000

- Standard 3-axis Machining Center: ¥300,000-800,000

- 4-axis Machining Center: ¥800,000-1,500,000

- 5-axis Machining Center: ¥1,500,000-5,000,000

- Economic CNC Lathe: ¥100,000-200,000

- Standard CNC Lathe: ¥200,000-500,000

- Turn-Mill Center: ¥500,000-1,500,000

- High-end Turning Center: ¥1,500,000-3,000,000

5.3 Operating Cost Analysis

- Average milling tool life: 10-40 hours

- Average turning tool life: 5-20 hours

- Milling tool cost per hour: ¥10-30/hour

- Turning tool cost per hour: ¥8-25/hour

- Milling machine operator requirements: Intermediate to advanced skills

- Lathe operator requirements: Intermediate skills

- Milling programming complexity: Higher

- Turning programming complexity: Medium

6. How to Choose: The Best Choice is the Most Suitable One

6.1 7 Signs to Choose Milling

- Complex Part Geometry

-

- Need to machine complex 3D curved surfaces

-

- Have multiple planes and angles

-

- Include complex features like grooves and hole systems

- Extremely High Precision Requirements

-

- Tolerance requirements less than ±0.02mm

-

- Need good surface roughness (Ra < 1.6μm)

-

- Have strict geometric tolerance requirements

- Special Materials

-

- Machining materials harder than HRC45

-

- Need to machine composites or special alloys

-

- Materials are expensive and need to minimize waste

- Small Production Batches

-

- Prototyping or small batch production (<100 pieces)

-

- High-mix low-volume production mode

-

- Need for quick changeover

- Special Part Structures

-

- Have deep cavity or narrow slot structures

-

- Need to machine thin-walled parts

-

- Have special surface texture requirements

- High Machining Freedom Requirements

-

- Need multi-angle machining

-

- Cannot be completed with a single clamping

-

- Need complex tool paths

- Innovative Design Needs

-

- Product in R&D stage

-

- Need for rapid design iteration

-

- Frequent design changes

6.2 5 Situations to Choose Turning

- Symmetric Part Geometry

-

- Axisymmetric or rotationally symmetric parts

-

- Mainly cylindrical or conical shapes

-

- Can be machined by rotating around a central axis

- Large Production Batches

-

- High-volume production (>500 pieces)

-

- Highly standardized parts

-

- Need for high-efficiency production

- Large Aspect Ratio

-

- Slender parts with aspect ratio greater than 3:1

-

- Shaft or rod parts

-

- Need good straightness

- Special Surface Requirements

-

- Need mirror turning effect

-

- Have threading requirements

-

- Need good cylindricity

- Cost Sensitivity

-

- Strict cost control requirements

-

- Intense market competition

-

- Need for standardized production

6.3 The Wisdom of Hybrid Machining

- Turn-Mill Composite Machining

-

- Complete turning and milling on the same machine

-

- Reduce clamping times and improve precision

-

- Suitable for complex rotational parts

- Process Division of Labor

-

- Turning completes rotational feature machining

-

- Milling completes complex feature machining

-

- Improve efficiency through reasonable division of labor

- Flexible Manufacturing Systems

-

- Multiple machines form a production line

-

- Automated loading and unloading

-

- Achieve unmanned production

7. Technology Development Trends: The Future is Here

7.1 Development Directions of Milling Technology

- Micron-level milling technology (<10μm features)

- Nano-level surface roughness (Ra < 0.01μm)

- Intelligent precision compensation systems

- Ultra-high speed spindles (>40,000rpm)

- High-speed feed systems (>100m/min)

- Intelligent chatter suppression technology

- AI-driven process optimization

- Adaptive control technology

- Digital twin technology application

7.2 Innovation Trends in Turning Technology

- Ultra-precision turning (<0.1μm roughness)

- Hard turning technology (direct machining of HRC60+ materials)

- Nano-level positioning accuracy

- Turn-mill composite machining centers

- Multi-functional turning centers

- Modular tool systems

- Low-temperature cutting technology

- Minimum quantity lubrication systems

- Environmentally friendly cutting fluids

8. Getting Started Advice: Learning CNC Machining from Scratch

8.1 Learning Path Planning

- Fundamentals of mechanical manufacturing

- Fundamentals of materials science

- Engineering drawing and CAD basics

- CAD software: SolidWorks, AutoCAD, etc.

- CAM software: Mastercam, UG, SolidCAM, etc.

- CNC system operation: Fanuc, Siemens, Mazak, etc.

- Safety operation training

- Equipment operation practice

- Process parameter debugging

- Complex part programming

- Process optimization technology

- Quality control methods

8.2 Recommended Software

- SolidWorks: Easy to learn and use, suitable for beginners

- AutoCAD: Industry standard, powerful functions

- Inventor: Autodesk product, good integration

- Mastercam: Comprehensive functions, suitable for milling and turning

- UG NX: High-end software, powerful functions

- SolidCAM: Seamless integration with SolidWorks

- VERICUT: Professional machining simulation software

- CIMCO Edit: Program editing and simulation

- MachineWorks: Real-time machining simulation

8.3 Practical Advice

- First practice basic plane and contour machining

- Gradually challenge complex 3D parts

- Accumulate machining experience with different materials

- Record cutting parameters for different materials

- Learn parameter optimization methods

- Understand the impact of parameters on quality

- Learn to use measuring tools

- Master dimensional tolerance control methods

- Establish quality inspection processes

- Follow new technology developments in the industry

- Participate in training and technical exchanges

- Try new machining methods

Conclusion: Technology is the Means, Application is the Purpose

- “CNC Milling Technology” – Machinery Industry Press

- “CNC Lathe Programming and Operation” – Higher Education Press

- “Modern Manufacturing Technology” – Tsinghua University Press

- Technical manuals from major CNC equipment manufacturers

- Industry technical standards and specifications

Disclaimer

- All information, opinions, and data contained in this article are for the purpose of information transmission only and do not constitute any advice on investment, transactions, law, medical care, or other matters.

- The content of the article is compiled based on public information or created based on the author’s personal understanding. Although every effort is made to ensure accuracy, it does not guarantee the completeness, accuracy, and timeliness of the information, nor does it bear any responsibility for any losses caused by the use of the content of this article.

- If the article involves third-party opinions, pictures, data, and other content, the copyright belongs to the original author. In case of infringement, please contact us for deletion.

- Readers should make independent decisions based on their actual situation and combined with professional opinions. The user shall bear all consequences arising from the use of the content of this article.