Introduction

In the world of precision manufacturing, the comparison between CNC milling and CNC turning precision has long been a topic of discussion among engineers, manufacturers, and procurement professionals. Both processes are essential in modern machining, but understanding their relative precision capabilities is crucial for selecting the right manufacturing method for specific applications.

This comprehensive technical article provides an in-depth analysis of CNC milling and turning precision, examining the factors that influence accuracy, typical tolerance ranges, surface finish capabilities, and practical considerations for choosing between these two fundamental machining processes.

Understanding CNC Milling and Turning Processes

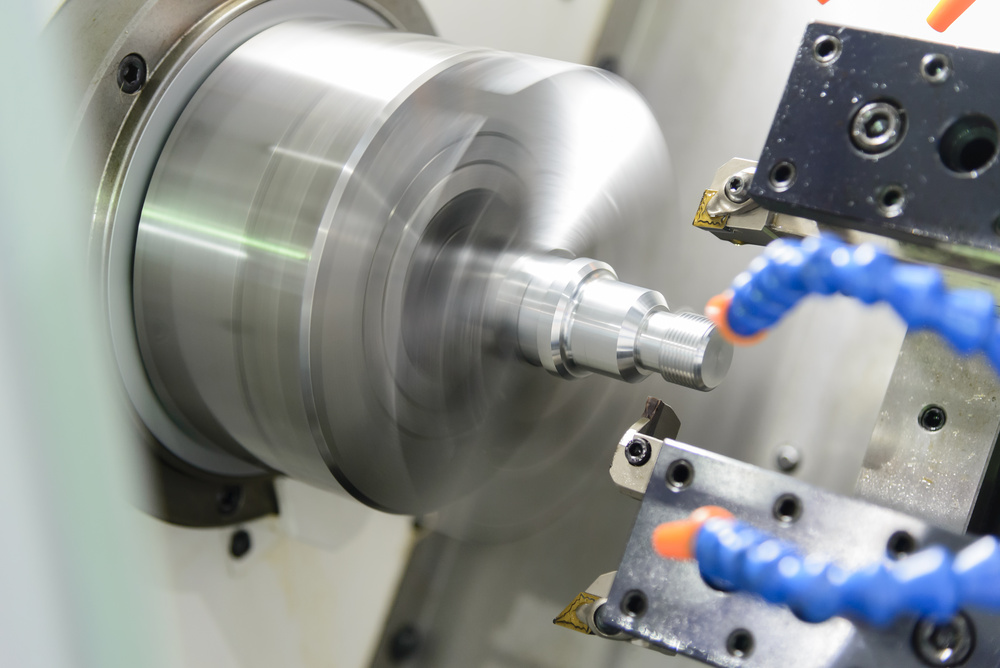

CNC Turning Fundamentals

CNC turning is a machining process where the workpiece rotates while a stationary cutting tool removes material to create cylindrical or conical shapes. This process is inherently suited for producing rotationally symmetric parts.

Key Characteristics:

- Workpiece rotates at high speeds (typically 500-5000 RPM)

- Cutting tool moves linearly along the X and Z axes

- Continuous cutting action with stable chip formation

- Single-point cutting tools with defined cutting edges

Typical Applications:

- Shafts, rods, and cylindrical components

- Threaded parts and fasteners

- Bushings, bearings, and sleeves

- Rotational components and assemblies

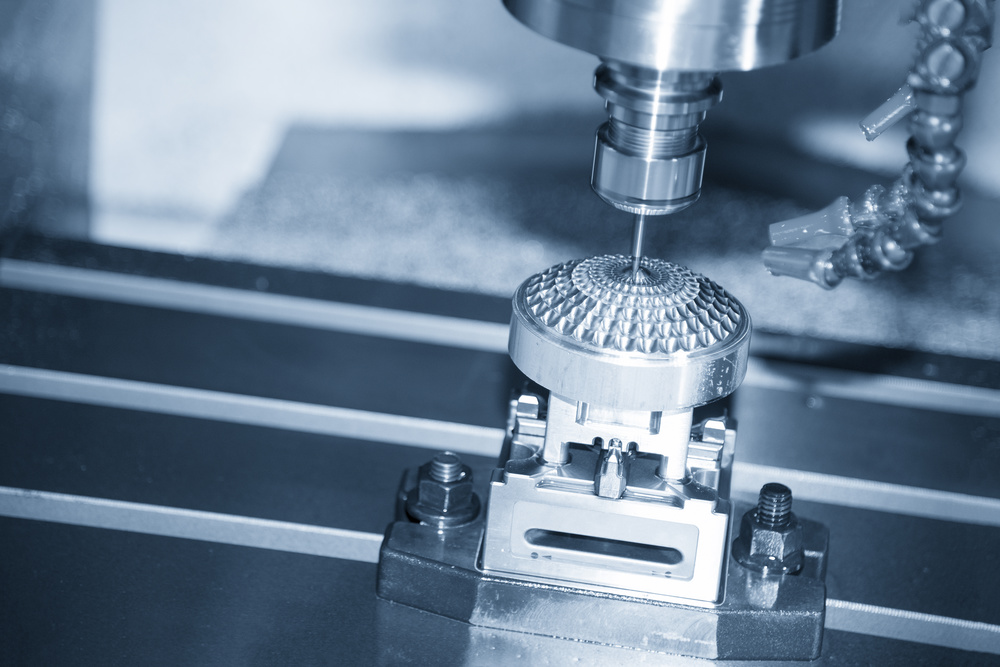

CNC Milling Fundamentals

CNC milling uses rotating multi-point cutting tools to remove material from a stationary workpiece. This versatile process can create complex three-dimensional shapes and features.

Key Characteristics:

- Cutting tool rotates at high speeds (1000-20000 RPM)

- Workpiece moves along X, Y, and Z axes (3-axis milling)

- Intermittent cutting with periodic tool engagement

- Multi-point cutting tools with multiple flutes

Typical Applications:

- Complex 3D shapes and contours

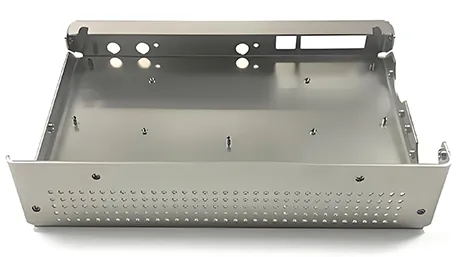

- Brackets, housings, and structural components

- Prototyping and custom parts

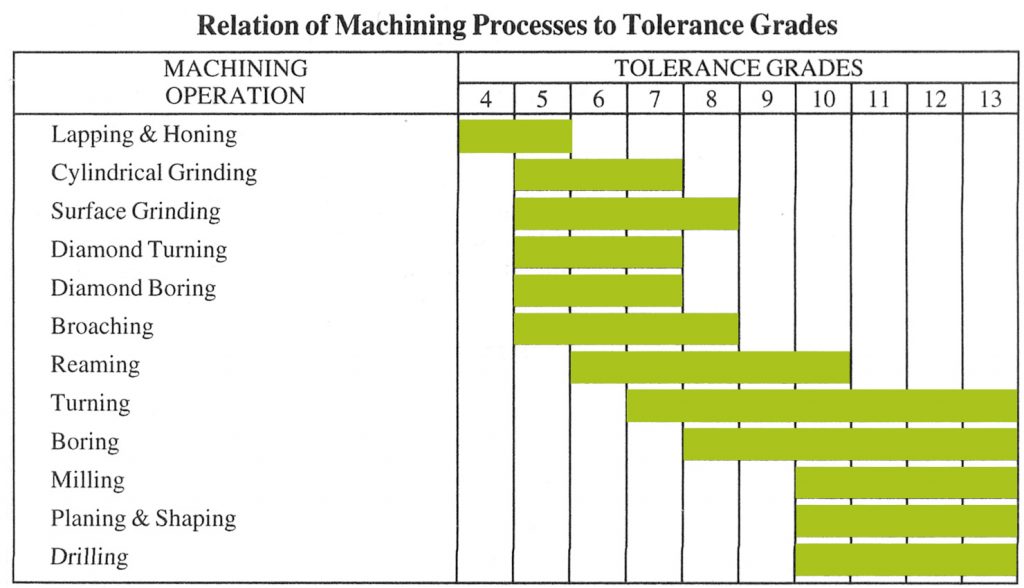

Precision Comparison: Tolerance Capabilities

CNC Turning Tolerance Ranges

CNC turning generally offers superior tolerance capabilities compared to standard milling processes due to its simpler kinematic system and continuous cutting action.

Standard Tolerances:

- Dimensional Tolerances: ±0.005 to ±0.01 mm (±0.0002 to ±0.0004 inches)

- Geometric Tolerances: Roundness: 0.001-0.003 mm, Concentricity: 0.002-0.005 mm

- Surface Finish: Ra 0.4-1.6 μm

High-Precision Turning:

- Dimensional Tolerances: ±0.002 to ±0.003 mm (±0.00008 to ±0.00012 inches)

- Geometric Tolerances: Roundness: 0.0005-0.001 mm, Concentricity: 0.001-0.002 mm

- Surface Finish: Ra 0.2-0.4 μm

CNC Milling Tolerance Ranges

CNC milling tolerances are generally slightly wider than turning but offer greater geometric flexibility.

Standard 3-Axis Milling:

- Dimensional Tolerances: ±0.01 to ±0.02 mm (±0.0004 to ±0.0008 inches)

- Geometric Tolerances: Flatness: 0.005-0.01 mm/m, Perpendicularity: 0.005-0.01 mm

- Surface Finish: Ra 1.6-3.2 μm

High-Precision Milling:

- Dimensional Tolerances: ±0.005 to ±0.01 mm (±0.0002 to ±0.0004 inches)

- Geometric Tolerances: Flatness: 0.002-0.005 mm/m, Perpendicularity: 0.002-0.005 mm

- Surface Finish: Ra 0.8-1.6 μm

5-Axis High-Precision Milling:

- Dimensional Tolerances: ±0.003 to ±0.005 mm (±0.00012 to ±0.0002 inches)

- Geometric Tolerances: Complex geometries with tight angular tolerances

- Surface Finish: Ra 0.4-0.8 μm

Factors Influencing Machining Precision

Machine Design and Rigidity

CNC Turning Machines:

- Generally more rigid design with shorter tool paths

- Heavier castings and more robust spindle systems

- Simpler kinematic chain with fewer moving parts

- Better damping characteristics for vibration control

CNC Milling Machines:

- More complex multi-axis movement systems

- Longer tool overhangs increasing deflection

- Multiple moving components introducing potential errors

- Advanced control systems compensating for errors

Cutting Tool Factors

Turning Tools:

- Single-point tools with defined cutting edges

- Lower cutting forces due to continuous cutting

- Better heat dissipation through tool shank

- Longer tool life with consistent performance

Milling Tools:

- Multi-point tools with multiple cutting edges

- Intermittent cutting causing cyclic loading

- Higher cutting forces requiring stronger tool holders

- More complex tool geometry affecting accuracy

Workpiece Material and Geometry

Material Effects:

- Hard Materials: Both processes require specialized tools and slower speeds

- Soft Materials: Turning offers better surface finish, milling may cause burrs

- Ductile Materials: Turning produces continuous chips, milling produces segmented chips

- Brittle Materials: Milling may cause chipping, turning offers more controlled cutting

Geometry Considerations:

- Cylindrical Parts: Turning provides superior roundness and concentricity

- Complex 3D Shapes: Milling offers unmatched geometric flexibility

- Thin-Walled Parts: Turning causes less distortion due to lower cutting forces

- Large Flat Surfaces: Milling is more efficient but may have flatness issues

Surface Finish Comparison

Surface Finish Capabilities

CNC Turning:

- Standard Finish: Ra 0.8-1.6 μm

- High-Precision Finish: Ra 0.2-0.4 μm

- Super Finishing: Ra 0.02-0.1 μm with specialized tools

- Consistent Finish: Uniform surface texture due to continuous cutting

CNC Milling:

- Standard Finish: Ra 1.6-3.2 μm

- High-Precision Finish: Ra 0.8-1.6 μm

- 5-Axis Finish: Ra 0.4-0.8 μm with fine tools

- Variable Finish: May show tool marks from intermittent cutting

Surface Finish Applications

Critical Surface Requirements:

- Sealing Surfaces: Turning provides better flatness and finish

- Bearing Surfaces: Turning offers superior roundness and surface texture

- Aesthetic Surfaces: Both processes can achieve high-quality finishes with proper tooling

- Functional Surfaces: Milling may require additional finishing operations

Application-Specific Precision Requirements

Aerospace Industry

Critical Requirements:

- Tolerance Levels: ±0.002-0.005 mm for structural components

- Surface Finish: Ra 0.4-0.8 μm for aerodynamic surfaces

- Material Considerations: Titanium, Inconel, and aluminum alloys

- Process Selection: Combination of turning and milling for complex components

Typical Applications:

- Turning: Engine shafts, turbine components, fasteners

- Milling: Structural brackets, wing components, complex housings

Medical Device Industry

Critical Requirements:

- Tolerance Levels: ±0.001-0.003 mm for implantable devices

- Surface Finish: Ra 0.1-0.4 μm for biocompatible surfaces

- Material Considerations: Titanium, stainless steel, ceramics

- Process Selection: Turning for cylindrical implants, milling for complex instruments

Automotive Industry

Critical Requirements:

- Tolerance Levels: ±0.005-0.01 mm for engine components

- Surface Finish: Ra 0.8-1.6 μm for functional surfaces

- Production Volume: High-volume production requiring consistent quality

- Cost Considerations: Balancing precision with production efficiency

How to Choose Between Milling and Turning

Decision-Making Factors

Part Geometry:

- Cylindrical Symmetry: Choose turning for better precision and efficiency

- Complex 3D Features: Choose milling for geometric flexibility

- Flat Surfaces: Milling is more efficient but turning may offer better finish

- Holes and Slots: Milling offers more flexibility for complex features

Precision Requirements:

- Tight Tolerances: Turning generally offers better dimensional accuracy

- Geometric Tolerances: Turning excels at roundness and concentricity

- Complex Tolerances: Milling can achieve complex positional tolerances

- Surface Finish: Turning provides superior surface quality

Production Considerations:

- Volume Requirements: Turning is more efficient for high-volume cylindrical parts

- Lead Time: Milling may require more setup time for complex parts

- Cost Factors: Turning generally has lower tooling costs for simple parts

- Material Efficiency: Milling may generate more waste material

Hybrid Approaches

Mill-Turn Centers:

- Combine turning and milling capabilities in one machine

- Single setup for complex parts requiring both processes

- Improved accuracy through reduced part handling

- Higher equipment cost but lower overall production costs

Sequential Processing:

- Using turning for initial cylindrical features

- Followed by milling for complex geometric features

- Requires careful fixturing to maintain accuracy between operations

- May be more cost-effective for certain part geometries

Case Studies: Precision Machining Applications

Case Study 1: Aerospace Turbine Component

Part Requirements:

- Material: Titanium Ti-6Al-4V

- Tolerances: ±0.003 mm dimensional, 0.001 mm roundness

- Surface Finish: Ra 0.4 μm

- Geometry: Complex turbine blade with cylindrical root

Process Selection:

- Primary Process: 5-axis milling for blade airfoil

- Secondary Process: Precision turning for root section

- Finishing: Grinding for critical surfaces

- Result: Achieved all specified tolerances with excellent surface quality

Case Study 2: Medical Implant

Part Requirements:

- Material: Titanium Grade 5

- Tolerances: ±0.002 mm dimensional, 0.001 mm concentricity

- Surface Finish: Ra 0.2 μm

- Geometry: Cylindrical implant with threaded features

Process Selection:

- Primary Process: Swiss-type turning for cylindrical features

- Secondary Process: Thread milling for precision threads

- Finishing: Electropolishing for biocompatible surface

- Result: Perfect concentricity and surface finish achieved

Case Study 3: Automotive Transmission Shaft

Part Requirements:

- Material: Alloy Steel 4140

- Tolerances: ±0.005 mm dimensional, 0.002 mm roundness

- Surface Finish: Ra 0.8 μm

- Geometry: Multi-diameter shaft with keyways

Process Selection:

- Primary Process: CNC turning for cylindrical features

- Secondary Process: Milling for keyways and flats

- Heat Treatment: Carburizing and tempering

- Finishing: Grinding for bearing surfaces

- Result: High production efficiency with consistent quality

Future Trends in Machining Precision

Advanced Control Systems

AI-Powered Machining:

- Adaptive control systems that optimize cutting parameters in real-time

- Machine learning algorithms that predict tool wear and adjust accordingly

- Virtual machining simulations that identify potential accuracy issues before production

- Enhanced error compensation for thermal and mechanical effects

Digital Twin Technology:

- Virtual replicas of machining processes for optimization

- Real-time monitoring and adjustment of production parameters

- Predictive maintenance to prevent accuracy degradation

- Improved process documentation and traceability

Machine Tool Advancements

High-Precision Spindles:

- Ultra-high-speed spindles with improved dynamic balance

- Thermal stability systems that maintain consistent temperatures

- Advanced bearing technologies for reduced runout

- Increased rigidity and damping characteristics

Multi-Axis Machining:

- 5-axis and 6-axis machines with improved accuracy

- Integrated turning and milling capabilities

- Advanced tool changers with improved repeatability

- Enhanced motion control systems for complex geometries

Conclusion: Making the Right Precision Choice

The question of whether CNC milling or turning offers higher precision does not have a simple answer—it depends on the specific application requirements. Based on our technical analysis:

Key Takeaways

CNC Turning Advantages:

- Superior dimensional accuracy for cylindrical parts

- Better roundness and concentricity capabilities

- Excellent surface finish for rotational components

- Lower cutting forces reducing workpiece distortion

CNC Milling Advantages:

- Unmatched geometric flexibility for complex 3D shapes

- Better suited for non-symmetrical part geometries

- More efficient for large flat surfaces and complex features

- Capable of producing intricate details and fine features

Recommendations

Choose CNC Turning When:

- Part geometry is primarily cylindrical or rotationally symmetric

- Tight roundness and concentricity tolerances are required

- Superior surface finish is critical

- High production volume of similar parts

Choose CNC Milling When:

- Part geometry is complex or non-symmetrical

- Multiple features are required on different faces

- Prototyping or low-volume production is needed

- Complex 3D shapes are required

Choose Hybrid Approaches When:

- Parts have both cylindrical and complex geometric features

- Single setup is needed to maintain accuracy

- Production efficiency is a critical factor

- Long-term cost savings justify higher equipment investment

Frequently Asked Questions (FAQ)

Q: Which process is more accurate for cylindrical parts?

A: CNC turning is generally more accurate for cylindrical parts, offering better roundness, concentricity, and dimensional stability.

Q: Can CNC milling achieve the same tolerances as turning?

A: High-precision CNC milling can achieve similar dimensional tolerances (±0.003-0.005 mm) but generally cannot match turning’s geometric tolerances for roundness and concentricity.

Q: Which process produces a better surface finish?

A: CNC turning typically produces a better surface finish (Ra 0.4-0.8 μm) compared to standard milling (Ra 1.6-3.2 μm), especially for cylindrical surfaces.

Q: Is 5-axis milling more accurate than 3-axis milling?

A: 5-axis milling offers better geometric accuracy for complex parts by reducing setup errors and improving tool access, but may have slightly wider dimensional tolerances than high-precision 3-axis milling.

Q: How does material selection affect machining precision?

A: Material properties significantly affect precision. Hard materials require specialized tools and slower speeds, while soft materials may deform more easily. Ductile materials are generally easier to machine with consistent precision.

Q: What is the most precise machining process?

A: For cylindrical parts, precision turning offers the highest accuracy. For complex 3D shapes, 5-axis high-precision milling is the most capable process. For ultimate precision, grinding and lapping processes are used after machining.

Q: How can I improve machining precision?

A: Precision can be improved through proper machine maintenance, using high-quality tools, optimizing cutting parameters, controlling environmental conditions, and implementing advanced error compensation techniques.

Q: What is the cost difference between high-precision and standard machining?

A: High-precision machining can cost 20-50% more than standard machining due to specialized equipment, tooling, and longer processing times. However, this cost premium is often justified for critical applications.

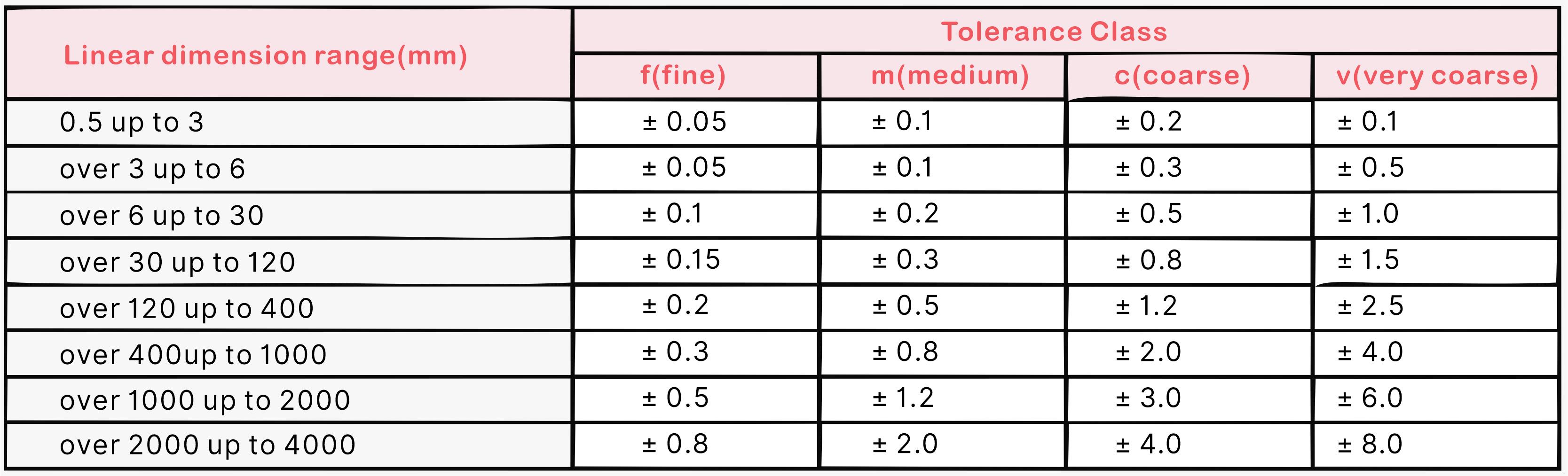

Q: How do I specify tolerances correctly for my part?

A: Tolerances should be specified based on functional requirements, not manufacturing capabilities. Work with your machining partner to determine the most cost-effective tolerances that meet your part’s performance needs.

Q: What trends are affecting machining precision?

A: Advancements in control systems, machine tool design, cutting tool technology, and AI-powered optimization are all contributing to continuous improvements in machining precision and capabilities.

Disclaimer

- All information, opinions, and data contained in this article are for the purpose of information transmission only and do not constitute any advice on investment, transactions, law, medical care, or other matters.

- The content of the article is compiled based on public information or created based on the author’s personal understanding. Although every effort is made to ensure accuracy, it does not guarantee the completeness, accuracy, and timeliness of the information, nor does it bear any responsibility for any losses caused by the use of the content of this article.

- If the article involves third-party opinions, pictures, data, and other content, the copyright belongs to the original author. In case of infringement, please contact us for deletion.

- Readers should make independent decisions based on their actual situation and combined with professional opinions. The user shall bear all consequences arising from the use of the content of this article.

CNC Milling vs Turning: Precision Comparison Guide

For more information on precision machining solutions or to discuss your specific application requirements, contact our technical team today.

Contact Information: