In the dynamic landscape of modern manufacturing, the demand for non – standard, uniquely shaped components has grown exponentially. CNC non – standard manufacturing of irregular parts on CNC lathes emerges as the ultimate solution, bridging the gap between complex design concepts and tangible, high – precision products. By leveraging the capabilities of Computer Numerical Control (CNC) technology, we can craft irregular parts with unparalleled accuracy, catering to the diverse and often unconventional requirements of various industries. This article delves into the technical prowess, customization process, material selection, quality control, and industry applications of CNC non – standard manufacturing of irregular parts on CNC lathes, highlighting its significance in driving innovation across sectors.

I. Technical Prowess: Mastering the Art of Irregularity

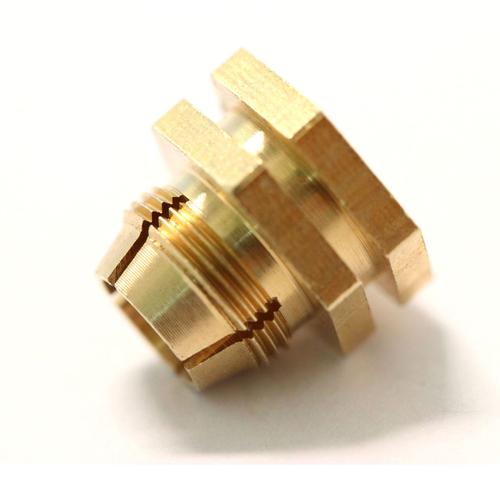

(A) Unrivaled Dimensional Accuracy

CNC lathes are meticulously calibrated to achieve exceptional dimensional accuracy, even for the most complex irregular parts. With positioning accuracy reaching ±0.003mm and repeat positioning accuracy of ±0.005mm, we can fabricate parts with extremely tight tolerances. For instance, when manufacturing a uniquely shaped shaft with varying diameters and intricate profiles for a specialized mechanical system, every dimension can be maintained within these precise limits. This level of accuracy ensures a perfect fit within assemblies, minimizing clearances and enhancing the overall performance and reliability of the final product.

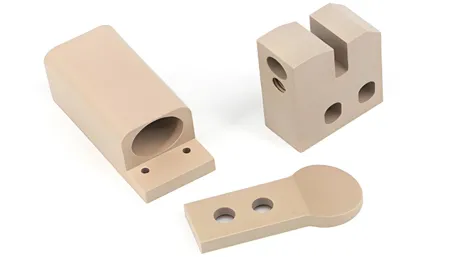

(B) Complex Geometry Machining

CNC lathes, especially those equipped with multi – axis capabilities, are designed to handle the machining of irregular parts with ease. Whether it’s parts with asymmetrical shapes, free – form curves, or complex internal cavities, the advanced programming and control systems of CNC lathes can execute these designs with precision. Specialized turning, milling, and boring operations can be combined in a single setup, reducing the need for multiple machining processes and minimizing errors. Compared to traditional machining methods, CNC lathes can achieve a higher degree of accuracy, reducing setup – related errors from ±0.015mm to within ±0.005mm, and significantly improving production efficiency by up to 60%.

(C) Advanced Tooling and Programming Techniques

To tackle the challenges of machining irregular parts, we employ a range of advanced tooling and programming techniques. Custom – designed cutting tools, with specific geometries and coatings, are used to optimize the machining process for different materials and part shapes. For example, ball – nose end mills are ideal for machining curved surfaces, while indexable inserts offer versatility and cost – effectiveness for various turning operations. In terms of programming, our skilled engineers use state – of – the – art CAD/CAM software to generate precise toolpaths that conform to the complex geometries of the parts. Advanced algorithms are utilized to calculate the optimal cutting speeds, feed rates, and tool engagement angles, ensuring a smooth machining process and a high – quality surface finish.

II. End – to – End Customization: From Concept to Reality

(A) In – Depth Requirement Analysis and Design Conceptualization

When you approach us with your need for CNC non – standard irregular parts, our experienced engineering team initiates in – depth discussions to understand your application, performance expectations, and design preferences. We consider factors such as the intended use of the part, the operating environment (temperature, humidity, corrosive conditions), the mechanical loads it will endure, and any specific functional or aesthetic requirements. Using 3D modeling software, we create detailed design concepts that visualize the part’s form and functionality. We then collaborate closely with you, refining the designs based on your feedback until they perfectly align with your vision, whether it’s a minor modification to an existing design or a completely new concept for a specialized project.

(B) Strategic Material Selection and Cost Analysis

Based on the finalized design, we recommend the most suitable materials for your irregular parts. The choice of material depends on various factors, including strength, durability, corrosion resistance, heat tolerance, and cost. For applications requiring high strength and wear resistance, materials like alloy steels and tool steels are often preferred. In contrast, for lightweight and corrosion – resistant applications, aluminum alloys and stainless steels are excellent options. Simultaneously, we conduct a detailed cost analysis, factoring in material costs, machining complexity, the need for custom tooling, and production volume, to provide you with a transparent and competitive quote.

(C) Precision Manufacturing and Order Tracking

Once you approve the design and quote, production commences. You can monitor the progress of your order in real – time through our dedicated online tracking platform. Our skilled technicians operate state – of – the – art CNC lathes, following strict manufacturing standards to produce parts that meet the highest quality benchmarks. We keep you informed at every stage of the production process, from raw material procurement to the final inspection, ensuring complete transparency and peace of mind throughout the manufacturing journey.

(D) Rigorous Quality Assurance and Timely Delivery

After production, each irregular part undergoes a rigorous quality inspection. Only parts that meet our exacting standards are shipped to you. We perform dimensional inspections using coordinate measuring machines (CMMs) to ensure that all critical dimensions are within ±0.003mm. Surface finish measurements are taken to ensure that the surface meets the required roughness specifications for optimal functionality and aesthetics. In addition, we conduct mechanical tests, such as tensile strength testing, hardness testing, and fatigue testing, to validate the performance of the parts. We also offer comprehensive after – sales support, addressing any concerns you may have during the product’s lifecycle.

III. Strategic Material Selection: Matching Materials to Requirements

(A) Alloy Steels

Alloy steels are a popular choice for CNC non – standard irregular parts due to their high strength, toughness, and excellent wear resistance. They contain alloying elements such as chromium, nickel, molybdenum, and vanadium, which enhance their mechanical properties. For example, 4140 alloy steel, with its good combination of strength and hardenability, is commonly used for parts that are subject to high stress and heavy loads, such as shafts, gears, and connecting rods in industrial machinery.

(B) Aluminum Alloys

Aluminum alloys are highly valued for their lightweight properties, good corrosion resistance, and excellent formability. Alloys like 6061 – T6 and 7075 – T6 are frequently used in applications where weight reduction is crucial without sacrificing strength. In the aerospace and automotive industries, aluminum alloy irregular parts are used for components such as brackets, housings, and structural elements, contributing to improved fuel efficiency and performance.

(C) Stainless Steels

Stainless steels are preferred for applications where corrosion resistance is of utmost importance. They contain chromium, which forms a passive oxide layer on the surface, protecting the material from rust and chemical attack. 304 stainless steel, with its good corrosion resistance and formability, is suitable for a wide range of applications, including food processing equipment, medical devices, and marine components. For more aggressive environments, 316 stainless steel, which contains molybdenum for enhanced corrosion resistance, is often selected.

(D) Plastics and Composites

In some cases, plastics and composite materials are used for CNC non – standard irregular parts. Plastics offer advantages such as low cost, lightweight, and good electrical insulation properties. Engineering plastics like ABS, nylon, and PEEK are commonly used for parts in the electronics, consumer goods, and medical industries. Composites, on the other hand, combine the benefits of different materials, offering high strength – to – weight ratios and excellent performance in specific applications, such as aerospace and sports equipment.

IV. Stringent Quality Control: Ensuring Excellence in Every Part

(A) Raw Material Inspection

All incoming raw materials for CNC non – standard irregular parts are subject to strict quality checks. We use spectroscopic analysis to verify the chemical composition of the materials, ensuring that they meet the required standards. Additionally, hardness testing, tensile testing, and microstructure analysis are performed to ensure the material’s integrity and suitability for the intended application. For example, when using alloy steel, we confirm that the alloying element ratios and mechanical properties meet the specified requirements.

(B) In – Process Monitoring

Throughout the manufacturing process, we employ statistical process control (SPC) techniques to monitor key manufacturing parameters. Regular sampling and data collection help us identify and correct any potential issues promptly. We monitor parameters such as cutting speeds, feed rates, tool wear, and the temperature during machining. If any parameter deviates from the set values, we can adjust the process in real – time to ensure consistent product quality, maintaining the precision and reliability of each irregular part.

(C) Final Product Validation

Before shipping, each part undergoes a comprehensive inspection. We use CMMs to verify dimensional accuracy, ensuring that all critical dimensions are within ±0.003mm. Surface roughness measurements are taken to ensure that the surface finish is optimized for the part’s intended function. Non – destructive testing methods, such as ultrasonic testing and dye penetrant inspection, are used to detect any internal or surface – breaking defects. Only parts that pass all these tests are considered ready for delivery.

V. Diverse Industry Applications: Meeting Unconventional Demands

(A) Aerospace Industry

In the aerospace industry, the demand for CNC non – standard irregular parts is high, as aircraft and spacecraft require components with unique shapes and precise dimensions. Our custom – made parts, such as turbine blades with complex airfoil profiles, structural brackets with irregular geometries, and engine components with intricate internal passages, are manufactured with the highest level of precision using advanced materials and machining techniques. These parts contribute to the lightweight design, improved aerodynamics, and enhanced performance of aerospace vehicles.

(B) Automotive Industry

The automotive industry also benefits from CNC non – standard manufacturing of irregular parts. Custom – designed components such as engine mounts with unique shapes for better vibration isolation, exhaust system parts with complex bends for optimized flow, and interior trim pieces with intricate contours for aesthetic appeal are all produced using CNC lathes. These parts not only improve the functionality and performance of vehicles but also add to their visual appeal.

(C) Medical Industry

In the medical field, CNC non – standard irregular parts are used in a variety of applications, including surgical instruments, medical devices, and prosthetics. For example, custom – made orthopedic implants with irregular shapes that conform to the patient’s anatomy, dental prosthetics with complex geometries for a perfect fit, and surgical tools with specialized profiles for precise procedures are all manufactured using CNC lathes. The high precision and quality of these parts ensure the safety and effectiveness of medical treatments.

(D) Art and Design

The art and design industries also rely on CNC non – standard manufacturing to bring their creative visions to life. Irregular – shaped sculptures, decorative elements, and unique furniture pieces can be fabricated with precision using CNC lathes. The ability to create complex geometries and intricate details allows artists and designers to push the boundaries of traditional craftsmanship and create truly one – of – a – kind works of art.

VI. Frequently Asked Questions (FAQ)

(A) What is the typical precision of CNC non – standard irregular parts?

Our CNC lathes can achieve a dimensional tolerance of ±0.003mm, ensuring precise fit and optimal performance for your unique parts.

(B) How long does it take to manufacture non – standard irregular parts?

Lead times vary depending on the complexity of the design, the materials used, and the order quantity. Simple designs can be completed in 3 – 5 days, while more complex ones may take 7 – 10 days. Rush orders are available upon request.

(C) Can you manufacture parts based on my own design drawings?

Yes, our team of experts can work with your design drawings or 3D models. We have the expertise to convert your designs into manufacturing – ready files and produce parts that meet your exact specifications.

(D) What types of materials can be used for non – standard irregular parts?

We can work with a wide range of materials, including metals (such as alloy steels, aluminum alloys, stainless steels), plastics, and composites. Our engineers will recommend the most suitable material based on your application requirements and budget.

(E) How do you ensure the quality of non – standard irregular parts?

We have a comprehensive quality control system in place, including raw material inspection, in – process monitoring, and final product validation. All parts are inspected using advanced measuring equipment and undergo various mechanical tests to ensure they meet our high – quality standards.

VII. Customer Testimonials

An aerospace research institute approached us to develop custom titanium alloy irregular parts for their new experimental aircraft. Our team utilized advanced CNC lathe machining and material selection techniques to create parts with complex geometries that met the strict aerospace standards. The new parts not only reduced the weight of the aircraft but also improved its aerodynamic performance. The institute was highly satisfied with the precision and quality of our custom – made parts, leading to further collaborations on future projects.

A medical device company needed custom – designed stainless steel irregular parts for their new line of surgical instruments. We designed and manufactured parts with specialized profiles using CNC lathes, ensuring a perfect fit and optimal functionality. The high – precision parts enhanced the performance of the surgical instruments, resulting in improved surgical outcomes. The company praised our attention to detail and the excellent quality of the parts, which helped them gain a competitive edge in the market.

Reach Out Now for Your CNC Non – Standard Manufacturing of Irregular Parts!

No matter how complex or unconventional your part design may be, our team of experts is ready to bring it to life. We offer a seamless end – to – end service, from design and material selection to manufacturing and quality assurance. Contact us today to discuss your project requirements and take the first step towards getting high – quality, custom – made CNC non – standard irregular parts that will meet your unique needs.