Ordering CNC parts involves a structured process of specifying requirements, collaborating with manufacturers, and ensuring precision production of custom components. From submitting design files to receiving finished parts, it relies on clear communication of dimensions, materials, tolerances, and post-processing needs. This process caters to industries like aerospace, automotive, and consumer goods, delivering tailored parts that meet functional, quality, and budgetary goals.

Detailed Guide to Ordering CNC Parts

1. Key Steps in the Ordering Process

Ordering CNC parts requires careful coordination between the customer and manufacturer, with each step critical to achieving the desired outcome:

-

Step 1: Define Requirements & Prepare Designs

Start by clarifying the part’s purpose, performance needs, and environmental conditions (e.g., temperature, corrosion exposure). Create detailed 3D CAD models using software like SolidWorks, Fusion 360, or AutoCAD, saved in universal formats (STEP, IGES, or STL) for manufacturer compatibility. Include critical specifications:- Dimensions & Tolerances: Specify nominal sizes and acceptable variances (e.g., ±0.01mm for precision holes, ±0.1mm for structural brackets). Use GD&T (Geometric Dimensioning and Tolerancing) to clarify critical features like flatness or positional accuracy.

- Material: Identify the material based on strength, weight, and machinability (e.g., aluminum 6061 for prototypes, stainless steel 316 for corrosion resistance).

- Volume: Indicate production quantity (prototype: 1–10 units; low-volume: 10–100; high-volume: 1000+), as this impacts manufacturing method and cost.

-

Step 2: Select a CNC Manufacturer

Choose a manufacturer with capabilities matching your needs. Key criteria include:- Machining Capabilities: Ensure they have equipment for your part’s complexity (3-axis for simple shapes, 5-axis for intricate 3D geometries).

- Certifications: Prioritize ISO 9001 (quality management) for general parts; AS9100 for aerospace, ISO 13485 for medical, or ITAR for defense components.

- Material Access: Verify they stock or can source your chosen material to avoid delays.

- Lead Time & Cost: Compare quotes, but balance cost with quality—cheaper options may compromise on precision or material grade.

-

Step 3: Design for Manufacturability (DFM) Review

Reputable manufacturers will conduct a DFM review to optimize the design for machining. They may suggest changes like:- Increasing internal radii to match standard tool sizes (e.g., ≥3mm radius for a 6mm end mill).

- Simplifying undercuts or deep slots to reduce tool deflection.

- Adjusting wall thickness to avoid warping (e.g., minimum 0.8mm for aluminum).

Approving these changes upfront reduces rework, delays, and costs.

-

Step 4: Quotation & Agreement

The manufacturer provides a detailed quote breaking down costs: material, machining time, post-processing, and shipping. Review lead times (typically 3–14 days for prototypes, 2–6 weeks for high-volume) and payment terms. Confirm details like surface finish (e.g., Ra 1.6μm for functional parts) and packaging (anti-static for electronics, crating for large components) before finalizing the order. -

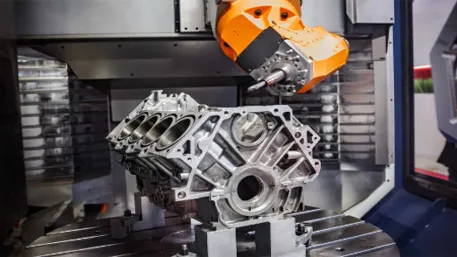

Step 5: Production & Quality Control

Manufacturing begins with material preparation (cutting billets to size) followed by CNC machining:- Roughing: Removing bulk material with high feed rates.

- Finishing: Achieving tight tolerances and smooth surfaces with precision tools.

In-process inspections using calipers, micrometers, or CMMs (Coordinate Measuring Machines) ensure compliance. Critical parts may undergo additional testing, such as X-ray for internal defects or hardness testing (e.g., 50–60 HRC for tool steel components).

-

Step 6: Post-Processing & Delivery

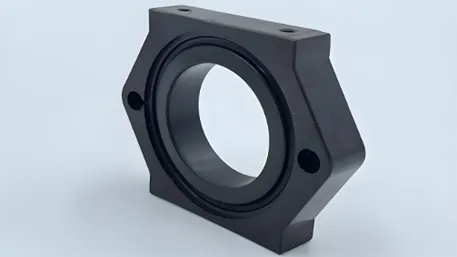

Post-processing steps (per your requirements) are applied:- Surface Treatments: Anodizing (aluminum), plating (zinc/nickel for steel), or powder coating for corrosion resistance and aesthetics.

- Heat Treatment: Annealing or tempering to enhance strength (e.g., 7075 aluminum aged to T6 condition).

- Deburring: Removing sharp edges for safety and fit.

Parts are then packaged and shipped via options like express courier (for urgent orders) or freight (for large volumes). Track shipments and inspect parts upon arrival to confirm they meet specifications.

2. Technical Considerations for Ordering

To avoid delays or defects, address these technical details upfront:

- Tolerances: Match tolerances to function—over-specifying (e.g., ±0.001mm for non-critical features) increases cost. For example, automotive brackets need ±0.1mm, while aerospace engine components require ±0.005mm.

- Surface Finish: Specify Ra values based on use: Ra 3.2μm for structural parts, Ra 0.8μm for sealing surfaces, and Ra 0.02μm for optical components.

- Part Complexity: Intricate features like thin walls (<1mm) or deep holes (>5× diameter) require experienced manufacturers with advanced tooling (e.g., micro-end mills for 0.5mm slots).

- Material Compatibility: Ensure post-processing works with the material—anodizing is only for aluminum; stainless steel may need passivation instead of plating to maintain corrosion resistance.

3. Material Selection for Ordered CNC Parts

Choosing the right material impacts performance, cost, and machinability:

-

Aluminum Alloys:

- 6061: Versatile, cost-effective, and easy to machine—ideal for prototypes, consumer goods, and structural parts.

- 7075: High-strength (570 MPa tensile strength) for aerospace or racing components, though harder to machine and pricier.

-

Steels:

- 1018 Mild Steel: Affordable, machinable, and weldable—used for brackets, shafts, and low-stress parts.

- 304 Stainless Steel: Corrosion-resistant, suitable for food processing, marine, or medical parts (requires slower machining to avoid work hardening).

- 4140 Alloy Steel: Heat-treatable for high strength, used in automotive gears or tooling.

-

Titanium (Ti-6Al-4V):

Lightweight, high-strength, and biocompatible—used in aerospace, medical implants, and high-performance racing parts. Expensive and requires specialized machining (slow feeds, coolant) due to low thermal conductivity. -

Plastics:

- PEEK: Heat and chemical resistant, used in medical and aerospace components.

- ABS: Low-cost, easy to machine—suited for prototypes or non-structural parts like enclosures.

4. Industry-Specific Ordering Scenarios

Ordering CNC parts varies by industry, driven by unique requirements:

- Aerospace: Demands certified materials (e.g., AMS 4037 aluminum), traceability (material lot numbers), and tight tolerances. Manufacturers must meet AS9100 standards, and parts often require ultrasonic testing to detect flaws.

- Medical Devices: Requires biocompatible materials (titanium, PEEK), smooth surfaces (Ra <0.05μm to prevent bacterial buildup), and compliance with ISO 13485. Parts like surgical instrument handles or implant components need rigorous documentation.

- Automotive: Focuses on cost efficiency and high-volume production. Orders often include prototypes for testing, followed by low-volume runs (100–500 units) before scaling to mass production (10,000+). Materials like 6061 aluminum and 1018 steel are common.

- Consumer Electronics: Prioritizes lightweight materials (aluminum, magnesium) and tight tolerances for fit (e.g., smartphone frame gaps <0.1mm). Surface finishes like anodizing or laser engraving enhance aesthetics.

- Custom & Hobby Projects: Enthusiasts often order small batches (1–10 units) of parts like custom brackets, drone components, or vintage car replacements. Manufacturers may offer quick-turn prototyping services for these orders.

5. Common Challenges & Solutions

- Unclear Specifications: Vague CAD files or missing tolerances cause rework. Solution: Provide detailed 3D models with annotated drawings and DFM checklists.

- Material Shortages: Delays occur if the manufacturer lacks your material. Solution: Choose manufacturers with in-house material stock or confirm lead times for specialty materials (e.g., titanium).

- Cost Overruns: Complex designs or tight tolerances increase prices. Solution: Collaborate on DFM early to simplify features without compromising function.

- Quality Issues: Parts failing inspection due to poor machining. Solution: Select manufacturers with robust QA processes and request first-article inspection for critical orders.

Ordering CNC parts successfully hinges on clear communication, precise specifications, and partnering with capable manufacturers. By following structured steps—from design to delivery—and addressing technical and industry-specific needs, you ensure the final parts meet performance, quality, and budget requirements.