CNC powder molding, i.e. Computer Numerical Control Powder Metallurgy Molding Technology, is an advanced manufacturing process that uses a high-precision CNC system to control presses or hydraulic presses to accurately press and mold metal powders. This technology combines the advantages of powder metallurgy and CNC technology, and is able to realize the mass production of complex shapes, high-precision and high-performance products, which are widely used in many fields, such as automotive, aerospace, medical devices, electronic communications and so on.

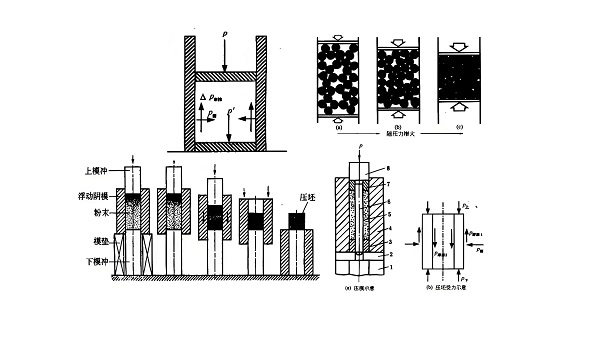

1. Technical principle of CNC powder molding

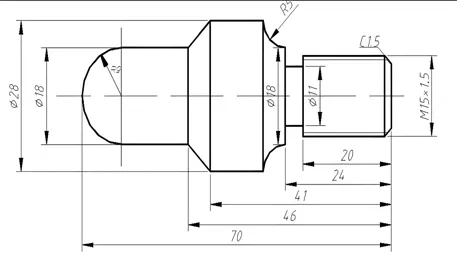

The technical principle of CNC powder molding mainly includes four key steps: powder preparation, mold design, press molding and subsequent processing. First of all, according to the product requirements to select the appropriate metal powder material, and pre-treatment, such as sieving, mixing, etc., to ensure that the particle size distribution of the powder is uniform and free of impurities. Second, design and manufacture a high-precision mold according to the shape and size requirements of the product. Subsequently, the powder is loaded into the mold, and the pressure is applied by a CNC system that precisely controls the press or hydraulic press to densify and shape the powder inside the mold. Finally, demolding and subsequent processing, such as sintering and heat treatment, are performed to improve the mechanical properties and dimensional stability of the product.

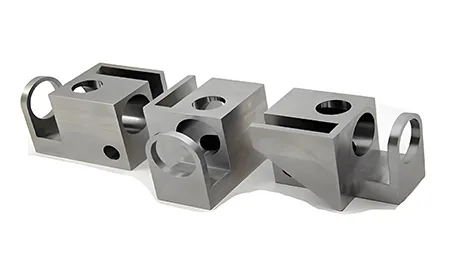

2.CNC Powder Molding Product Customization

CNC powder molding technology provides great flexibility for product customization. Customers can customize various shapes, sizes and performance requirements of metal powder molding parts according to their own needs. From simple cylinders to complex shaped parts, CNC powder molding technology can easily deal with. In addition, by adjusting the parameters of the pressing process and the subsequent treatment process, it can further meet the customer’s special requirements for product performance, such as improving the hardness, abrasion resistance, corrosion resistance and so on.

3.CNC powder molding material selection and characteristics

CNC powder molding material selection of a wide range of metal powders, including iron-based powder, copper-based powder, nickel-based powder, cobalt-based powder and other metal powders. These powder materials have different physical and chemical properties, such as density, hardness, toughness, corrosion resistance, etc., to meet the manufacturing needs of products in different areas. In the selection of materials, need to take into account the use of the product environment, performance requirements and cost and other factors.

4.CNC Powder Molding Product Characteristics Test Data

CNC powder molding product characteristics test data is an important basis for assessing product quality and performance. Common test items include density test, hardness test, tensile strength test, fatigue life test and so on. Take a certain model of automobile engine connecting rod as an example, its CNC powder molding parts after testing, the density of up to 7.8g/cm³, hardness of up to HRC35-40, tensile strength of up to 600MPa or more, fatigue life of up to millions of times or more. These test data show that CNC powder molding products have excellent mechanical properties and service life.

CNC Powder Molding FAQ

1. What are the advantages of CNC powder molding technology over traditional casting technology?

CNC powder molding technology has the advantages of high precision, high efficiency, high material utilization and excellent product performance. Compared with traditional casting technology, it can significantly reduce the machining allowance, reduce energy consumption and cost, and at the same time improve the dimensional accuracy and surface quality of the product.

2. What special properties can be customized for CNC powder molding products?

CNC powder molding products can be customized with a variety of special properties according to customer needs, such as improved hardness, wear resistance, corrosion resistance, fatigue resistance, and so on. These special properties can be optimized and enhanced by adjusting the parameters of the pressing process and the subsequent treatment process.

3. What is the production lead time for CNC powder molded products?

The production cycle of CNC powder molded products depends on a number of factors, including the complexity of the product, the production batch, and the raw material preparation time. Generally speaking, the entire production process from mold design to product delivery takes anywhere from a few weeks to a few months. However, with the improvement of automation and intelligence, the production cycle is expected to be further shortened.

4. In what fields is CNC powder molding technology widely used?

CNC powder molding technology is widely used in many fields, such as automotive, aerospace, medical devices, and electronic communications. For example, in the automotive field, CNC powder molding technology can be used to produce engine connecting rods, brake discs, gears and other key components; in the aerospace field, it can be used for the production of high-temperature alloy parts and complex shapes of structural components.