I. Overview: The Perfect Combination of Brass Materials and CNC Processing

Brass is an alloy composed of copper and zinc. Due to its excellent physical properties and processing characteristics, it has become an ideal choice for the manufacture of precision parts. In modern manufacturing, CNC (Computer Numerical Control) processing technology has become the core process for the manufacture of brass precision parts, enabling high-precision and high-efficiency production.

1.1 Characteristics and Classification of Brass Materials

Brass has a variety of good mechanical properties, including a low coefficient of friction, strong wear resistance, high corrosion resistance, ductility, and malleability. According to the proportion of copper and zinc and other added elements, common brass materials mainly include:

- H68 Brass: The copper content is approximately 67.0 – 70.0%. It has extremely good plasticity and relatively high strength. It has good machinability, is easy to weld, and is very stable against general corrosion.

- CW614N Leaded Brass: The copper content is approximately 57 – 59%, and the lead content is 2.5 – 3.5%. It has excellent cutting performance and is suitable for automatic lathe processing.

- CuZn25Al6Fe3Mn3 High – strength Brass: It contains elements such as aluminum, iron, and manganese. It has high strength, high hardness, and good wear resistance, and is suitable for manufacturing high – strength wear – resistant parts.

- ZCuZn25Al6Fe3Mn3 Aluminum Brass: It has very high mechanical properties, good casting performance, relatively good corrosion resistance, a tendency to stress – corrosion cracking, and can be welded.

1.2 Advantages of CNC Processing in the Manufacture of Brass Parts

CNC processing technology brings significant advantages to the manufacture of brass parts:

- High Precision: CNC processing can achieve extremely high processing accuracy, usually up to ±0.005mm, far higher than traditional processing methods.

- High Surface Quality: The surface roughness of brass parts processed by CNC can reach Ra1.6, close to a mirror effect, reducing the need for subsequent polishing processes.

- Complex Shape Machining Ability: CNC machine tools can complete the machining of various complex shapes. Especially machining centers equipped with 4 – axis and 5 – axis linkage functions can complete multi – surface machining in one clamping.

- High Material Utilization Rate: Compared with casting, CNC processing can increase the material utilization rate to more than 90%, significantly reducing resource consumption.

- High Production Efficiency: CNC processing has a high degree of automation and can achieve 24 – hour continuous production, greatly improving production efficiency.

II. Detailed Explanation of the Processing Technology of CNC Precision Brass Parts

2.1 Design and Programming Preparation Stage

2.1.1 Part Design and CAD Model Creation

The first step in CNC processing is to create an accurate part design model. Designers use Computer – Aided Design (CAD) software to create a three – dimensional model to determine the precise dimensions, shape, and tolerance requirements of the part. During the design process, the following points need to be particularly noted:

- Consider the Characteristics of Brass Materials: When designing, characteristics such as the ductility and coefficient of thermal expansion of brass need to be considered, and appropriate machining allowances should be reserved.

- Optimize the Geometric Shape: Avoid overly sharp internal corners and overly deep cavities to reduce tool wear and machining difficulty.

- Determine Reasonable Tolerances: According to the usage requirements of the part, set a reasonable tolerance range to avoid unnecessary high – precision requirements that increase processing costs.

2.1.2 CAM Programming and Tool Path Planning

After the CAD model is completed, Computer – Aided Manufacturing (CAM) software is needed to convert the design model into instruction codes that can be executed by a CNC machine tool. This process includes:

- Select the Processing Technology: According to the part shape and precision requirements, select appropriate processing technologies such as milling, turning, and drilling.

- Tool Selection: According to the characteristics of the brass material and the processing technology, select appropriate tool materials and geometric parameters. High – speed steel (HSS) and carbide are commonly used tool materials for processing brass, while polycrystalline diamond (PCD) tools are suitable for occasions with high – precision and high – surface – finish requirements.

- Tool Path Planning: Generate the tool movement trajectory and determine processing parameters such as cutting speed, feed rate, and cutting depth. For brass materials, a relatively high feed rate and a small cutting depth are usually adopted to improve processing efficiency and obtain a better surface finish.

- Program Verification: Check whether the tool path is correct by simulating the machining process to avoid problems such as collisions and over – cutting.

2.2 Material Preparation and Workpiece Clamping

2.2.1 Selection and Inspection of Brass Materials

Selecting the appropriate brass material is the key to ensuring the quality of the parts. When choosing brass materials, the following factors should be considered:

- Mechanical Property Requirements: According to the usage conditions of the part, select a brass material with appropriate strength, hardness, and toughness.

- Machinability: The machinability of brass materials with different compositions varies greatly. For example, lead – containing brass (CW614N) has excellent cutting performance and is suitable for automatic lathe processing; while high – strength brass (ZCuZn25Al6Fe3Mn3) has a higher hardness and requires more wear – resistant tools.

- Surface Quality Requirements: For parts with high surface quality requirements, brass materials with low impurity content and uniform structure should be selected.

Material inspection is also a crucial link, including dimensional accuracy inspection, hardness testing, and metallographic analysis, etc., to ensure that the material meets the processing requirements.

2.2.2 Workpiece Clamping and Positioning

The stability of workpiece clamping directly affects the processing accuracy and surface quality. When clamping brass workpieces, the following points should be noted:

- Select Appropriate Fixtures: According to the shape and size of the part, select clamping tools such as vises, chucks, or special fixtures.

- Avoid Surface Scratching: Since the brass material is relatively soft, the contact parts between the fixture and the workpiece should be protected with copper pads or soft materials to prevent scratching the workpiece surface.

- Ensure Positioning Accuracy: The workpiece should be positioned accurately and reliably to ensure that the processing datum is consistent with the design datum and reduce positioning errors.

- Consider Deformation during Processing: For thin – walled or slender parts, multi – point support or additional process supports should be used to prevent deformation caused by cutting forces during processing.

2.3 Detailed Explanation of the Cutting Processing Technology

2.3.1 Milling Processing Technology

Milling is one of the most commonly used processes for CNC processing of brass parts and is suitable for the processing of various features such as planes, contours, and cavities:

- Milling Tool Selection: Commonly used milling cutters for processing brass include end mills, vertical mills, and ball – nose mills. For high – precision processing, coated tools can be selected to improve tool life and processing surface quality.

- Optimization of Milling Parameters:

- Cutting Speed: The cutting speed for brass milling is usually in the range of 150 – 300 surface feet per minute (SFM).

- Feed Rate: The feed per tooth is approximately 0.002 – 0.005 inches, and it is specifically adjusted according to the tool diameter, material thickness, and surface finish requirements.

- Cutting Depth: It is determined according to the part structure and tool performance, generally 10 – 20% of the tool diameter.

- Milling Strategies:

- For face milling, the climb milling method should be adopted to reduce tool wear and surface roughness.

- For deep – cavity processing, layered cutting should be carried out to avoid overloading the tool due to excessive cutting depth at one time.

- For contour processing, spiral or ramp plunge – cutting methods should be adopted to reduce tool impact and breakage risks.

- 4 – axis and 5 – axis Processing: For brass parts with complex shapes, 4 – axis and 5 – axis processing can complete the processing of multiple surfaces in one clamping, reducing the number of clamping times and improving processing accuracy and efficiency.

2.3.2 Turning Processing Technology

Turning is mainly used for the processing of rotational parts such as shafts and sleeves:

- Turning Tool Selection: Select appropriate turning tools according to the processing characteristics, such as external turning tools, internal hole turning tools, and cutting – off tools. When turning brass, the rake angle of the tool should be appropriately increased to reduce cutting force and cutting heat.

- Optimization of Turning Parameters:

- Spindle Speed: It is adjusted according to the workpiece diameter and material hardness, generally 2500 – 10000 revolutions per minute (RPM).

- Feed Rate: It is usually 0.005 – 0.02 inches per revolution, and it is specifically adjusted according to the surface quality requirements.

- Cutting Depth: Generally, it should not exceed 1/3 of the tool radius to avoid overloading the tool.

- Turning Strategies:

- During rough turning, a larger cutting depth and feed rate should be adopted to improve the material removal rate.

- During finish turning, the feed rate and cutting depth should be reduced to improve the surface quality.

- For slender shaft – type parts, a follow – rest or center rest should be used to prevent workpiece deformation.

2.3.3 Drilling and Tapping Processes

Drilling and tapping are common processes for processing holes in brass parts:

- Drilling Process:

- Drill Bit Selection: Select an appropriate drill bit according to the hole diameter and depth. For deep – hole processing, an internal – cooling drill bit should be selected.

- Drilling Parameters: The drilling speed is generally 150 – 300 SFM, and the feed rate is approximately 0.005 – 0.01 inches per revolution.

- Precautions: To prevent the drill bit from breaking, a stepped feed method should be adopted, especially during deep – hole processing; at the same time, an appropriate cutting fluid should be used to reduce the cutting temperature.

- Tapping Process:

- Tap Selection: Select an appropriate tap according to the thread specification. For blind – hole threads, a spiral – fluted tap should be selected to facilitate chip removal.

- Tapping Parameters: The tapping speed should be lower than the drilling speed, generally 50 – 100 SFM, and the feed rate should match the thread pitch.

- Precautions: Before tapping, ensure that the bottom – hole diameter is correct; during tapping, reverse appropriately to prevent chip clogging; use an appropriate cutting fluid to improve the thread quality and tap life.

2.4 Surface Treatment Processes

To improve the corrosion resistance, wear resistance, and aesthetics of brass parts, surface treatment is usually required:

- Mechanical Surface Treatment:

- Polishing: Mechanical polishing can improve the surface finish and reduce the surface roughness.

- Sandblasting: Sandblasting treatment can obtain a uniform matte surface and improve the adhesion of subsequent coatings.

- Chemical Surface Treatment:

- Passivation Treatment: Through chemical passivation, a protective film can be formed on the surface of brass to improve corrosion resistance.

- Coloring Treatment: Through chemical coloring, the surface of brass can present different colors to meet decorative requirements.

- Electrochemical Surface Treatment:

- Electroplating: Electroplating a layer of metal (such as nickel, chromium, gold, etc.) on the surface of brass can improve corrosion resistance and decoration.

- Electropolishing: Through electropolishing, an extremely high surface finish can be obtained, which is suitable for high – precision parts.

- Special Surface Treatment:

- Brass Inlaying Process: Inlay brass with other materials (such as wood, metal, gemstones, etc.) to produce exquisite handicrafts or practical items.

- Laser Engraving: Use a laser to engrave patterns or text on the surface of brass, which has high precision and fast speed.

2.5 Quality Inspection and Control

Quality inspection is a key link to ensure the quality of CNC precision brass parts:

- Dimensional Accuracy Inspection:

- Measuring Tools: Conventional measuring tools such as calipers, micrometers, and height gauges are used for general dimensional inspection.

- Precision Measuring Equipment: For high – precision parts, a Coordinate Measuring Machine (CMM) is used for accurate measurement, with an accuracy of up to 0.3μm.

- Video Measuring Instrument: It is used for the measurement of complex shapes and small dimensions, with an accuracy of up to 0.8μm.

- Surface Quality Inspection:

- Surface Roughness Tester: Measure the surface roughness to evaluate the processing surface quality.

- Optical Microscope: Used to observe the surface microstructure and defects.

- Electron Microscope: Used for high – magnification observation to detect small defects.

- Internal Defect Inspection:

- Ultrasonic Testing: Used to detect internal cracks, pores, and other defects.

- X – ray Testing: Used to detect the internal structure and defects.

- Magnetic Particle Testing: Used to detect surface and near – surface defects.

- Quality Control System:

- First – Article Inspection: Conduct a comprehensive inspection of the first article of each batch to confirm that the processing parameters are correct.

- Patrol Inspection: Regularly spot – check the parts during the processing process to promptly discover problems.

- Finished Product Full Inspection: Conduct a 100% full inspection of key parts to ensure that the quality meets the requirements.

- Statistical Process Control (SPC): Monitor the processing process through statistical methods to prevent quality problems.

III. Process Optimization and Cost Control of Brass CNC Processing

3.1 Tool Selection and Life Optimization

Tools are the most important consumables in CNC processing. Reasonable tool selection and tool life optimization are crucial for reducing processing costs:

- Tool Material Selection:

- High – Speed Steel (HSS) Tools: They have good toughness and a moderate price, and are suitable for general brass processing.

- Carbide Tools: They have high hardness and good wear resistance, and are suitable for high – precision and high – efficiency processing.

- Polycrystalline Diamond (PCD) Tools: They have extremely high hardness and good wear resistance, and are suitable for high – surface – finish and high – precision processing, but the price is relatively high.

- Optimization of Tool Geometric Parameters:

- Rake Angle: When processing brass, the rake angle of the tool should be appropriately increased, generally 15 – 25 degrees, to reduce cutting force and cutting heat.

- Clearance Angle: The clearance angle should be appropriately reduced to increase tool strength, generally 6 – 10 degrees.

- Edge Inclination Angle: Select an appropriate edge inclination angle according to the processing technology to improve chip discharge performance.

- Tool Life Management:

- Establish a Tool Life Database: Record the life of different tools under different processing conditions to provide a basis for tool replacement.

- Tool Wear Monitoring: Monitor the tool wear situation through signals such as cutting force, vibration, and sound, and replace the tool in a timely manner.

- Tool Re – grinding and Refurbishment: Re – grind and refurbish worn tools to extend their service life and reduce costs.

3.2 Optimization of Cutting Parameters

Optimizing cutting parameters can improve processing efficiency and reduce processing costs:

- Optimization of Cutting Speed:

- The cutting speed for brass processing usually ranges from 150 – 300 SFM.

- For brass materials with higher hardness, the cutting speed should be appropriately reduced.

- For parts with high – precision and high – surface – finish requirements, the cutting speed should also be appropriately reduced.

- Optimization of Feed Rate:

- The feed rate affects processing efficiency and surface quality, and should be reasonably selected according to processing requirements.

- During rough machining, a larger feed rate can be adopted to increase the material removal rate.

- During finish machining, the feed rate should be decreased to improve the surface quality.

- Optimization of Cutting Depth:

- The cutting depth should be reasonably selected based on the tool diameter, machine tool power, and part structure.

- For difficult – to – machine areas such as deep cavities and deep grooves, layered cutting should be used to avoid excessive cutting depth at one time.

- For thin – walled and slender parts, the cutting depth should be reduced to prevent workpiece deformation.

- Cutting Fluid Selection:

- Water – soluble Cutting Fluid: It has a good cooling effect and a moderate price, making it suitable for general brass processing.

- Cutting Oil: It offers good lubrication, which can enhance the surface quality and tool life, but subsequent cleaning is required.

- Special Cutting Fluid: For high – precision and high – efficiency processing, special cutting fluids can be used to improve the processing effect.

3.3 Optimization of the Processing Process Route

Optimizing the processing process route can enhance processing efficiency and cut processing costs:

- Optimization of Processing Sequence:

- Roughing First, Finishing Later: First perform rough machining to remove most of the stock, and then carry out finish machining to ensure dimensional accuracy and surface quality.

- Main Surfaces First, Secondary Surfaces Later: Process the main surfaces and key dimensions first, followed by the secondary surfaces and non – key dimensions.

- Plane First, Hole Later: For parts with planes and hole systems, the plane should be processed first, and then the holes, to improve the machining accuracy of the holes.

- Concentration and Dispersion of Processes:

- Process Concentration: Completing multiple processing tasks in one clamping can reduce the number of clamping times and improve processing accuracy and efficiency.

- Process Dispersion: For complex parts, the processing tasks can be distributed among different processes to reduce the complexity and difficulty of a single process.

- The principle of process concentration or dispersion should be reasonably chosen according to the part structure and processing requirements.

- Optimization of Processing Path:

- Reduce Idle Travel: Optimize the tool path to minimize ineffective movement and boost processing efficiency.

- Avoid Re – positioning: Try to complete as many processing tasks as possible in one clamping to reduce positioning errors.

- Reasonable Arrangement of Tool Approach and Withdrawal: Adopt appropriate tool approach and withdrawal methods to reduce tool wear and processing defects.

3.4 Cost Analysis of Brass CNC Processing

Understanding the cost composition of CNC – processed brass parts helps optimize cost control:

- Material Cost:

- Brass Material Prices: In April 2025, the price of copper was approximately 79,100 yuan per ton, zinc about 25,000 yuan per ton, aluminum around 20,000 yuan per ton, iron approximately 5,000 yuan per ton, and manganese about 15,000 yuan per ton.

- Cost Differences among Different Brass Materials: For example, the material cost of ZCuZn25Al6Fe3Mn3 high – strength brass is about 57,920.5 yuan per ton. After adding processing fees and other costs, the total cost is approximately 69,500 yuan per ton, and the market quotation is around 80,000 yuan per ton.

- Material Utilization Rate: The material utilization rate of CNC – processed brass can reach over 90%, significantly reducing the material cost.

- Processing Cost:

- Equipment Depreciation: CNC machine tools are expensive, and depreciation costs are a significant part of the processing cost.

- Energy Consumption: The electricity, cutting fluid, etc., consumed during CNC processing are also part of the processing cost.

- Labor Cost: Expenses such as the wages and benefits of operators.

- Tool Consumption: Costs for tool purchase, re – grinding, and refurbishment.

- Management Cost:

- Production Management: Costs for production planning, scheduling, quality management, etc.

- Technology Research and Development: Expenses for new product development, process improvement, etc.

- Equipment Maintenance: Costs for equipment maintenance and repair.

- Batch Production Cost Analysis:

- Single – piece and Small – batch Production: The proportion of fixed costs is relatively high, resulting in a higher unit cost.

- Medium – batch Production: Fixed costs are allocated to more parts, reducing the unit cost.

- Large – batch Production: Special tooling and automated production lines can be used to improve production efficiency and lower the unit cost.

IV. Application and Development Trends of Modern CNC Processing Technology in Brass Part Manufacturing

4.1 Application of Advanced CNC Processing Technologies

Modern CNC processing technologies are constantly innovating, bringing new possibilities to brass part manufacturing:

- Five – axis Linkage Machining Technology:

- Five – axis linkage machining can complete the processing of complex surfaces in one clamping, reducing the number of clamping times and improving processing accuracy.

- It allows the use of shorter and more rigid tools, enhancing processing efficiency and surface quality.

- It is suitable for manufacturing brass parts with complex surfaces, such as art sculptures and precision molds.

- High – speed Machining Technology:

- High – speed machining can improve processing efficiency and shorten processing time.

- It can reduce cutting forces and lower the risk of workpiece deformation.

- It can improve surface quality and reduce subsequent processing steps.

- Composite Machining Technology:

- Turn – milling Composite Machining: Realizing turning and milling functions on one machine tool can reduce clamping times and improve processing accuracy.

- Drill – milling Composite Machining: Realizing drilling and milling functions on one machine tool can improve processing efficiency.

- Combination of Additive Manufacturing and Subtractive Manufacturing: Combining 3D printing with CNC processing enables the efficient manufacturing of complex structures.

- Intelligent Manufacturing Technology:

- Digital Twin Technology: By creating a virtual model, it can simulate and optimize the processing process.

- Internet of Things Technology: Real – time monitoring of the processing process through sensors enables intelligent management.

- Big Data Analysis: Analyzing processing data can optimize processing technology and equipment maintenance plans.

4.2 Application of AI in Brass CNC Processing

Artificial intelligence technology is increasingly widely used in brass CNC processing:

- AI – based Visual Inspection:

- AI – based visual inspection systems can quickly and accurately detect appearance defects of brass parts, such as burrs, cracks, and scratches.

- Deep – learning – based AI visual inspection systems can complete inspection tasks that traditionally take several minutes within 1 second.

- These systems can automatically identify the type and location of defects and generate inspection reports.

- AI – based Process Optimization:

- AI can optimize processing parameters and process routes based on processing data and empirical knowledge.

- AI can predict potential problems in the processing process and take preventive measures in advance.

- AI can automatically generate machining programs, improving programming efficiency and quality.

- AI – based Equipment Management:

- AI can predict equipment failures by analyzing equipment operation data and arrange maintenance in advance.

- AI can optimize equipment utilization and improve production efficiency.

- AI can achieve remote monitoring and diagnosis, improving equipment management efficiency.

- AI – based Quality Control:

- AI can identify the root causes of quality problems by analyzing processing data and quality inspection data.

- AI can establish quality prediction models to early – warn of quality risks.

- AI can automatically adjust processing parameters to ensure product quality consistency.

4.3 Green Manufacturing and Sustainable Development

With the increasing awareness of environmental protection, green manufacturing has become an important development direction for CNC processing:

- Application of Energy – saving Technologies:

- Adopting energy – saving CNC machine tools to reduce energy consumption.

- Optimizing processing technology to reduce processing time and energy consumption.

- Using technologies such as regenerative braking and energy – saving motors to lower energy consumption.

- Application of Emission – reduction Technologies:

- Using environmentally friendly cutting fluids to reduce harmful substance emissions.

- Adopting dry cutting or minimum quantity lubrication technologies to reduce the use of cutting fluids.

- Installing exhaust gas treatment equipment to reduce exhaust gas emissions during processing.

- Resource Recycling and Utilization:

- Recycling and using brass chips generated during processing to reduce raw material consumption.

- Using recyclable materials for product packaging to reduce packaging waste.

- Promoting product recycling and remanufacturing to extend the product life cycle.

- Low – carbon Manufacturing Model:

- Optimizing the production process to reduce unnecessary transportation and inventory.

- Promoting distributed manufacturing to reduce product transportation distance and carbon emissions.

- Using clean energy sources such as solar and wind energy to reduce carbon emissions.

4.4 Development Trends of CNC Processing Technology

Looking to the future, CNC processing technology will develop in the following directions:

- Higher Precision:

- Processing accuracy will be further improved, evolving from the micron – level to the nanometer – level.

- Ultra – precision processing technology will be widely applied in fields such as optics and electronics.

- New precision measurement technologies will continue to emerge to support high – precision processing.

- Higher Efficiency:

- High – speed and ultra – high – speed machining technologies will be more widely used.

- Multi – axis linkage and composite machining technologies will improve processing efficiency.

- Automated production lines will achieve unmanned and intelligent production.

- Intelligentization:

- Technologies such as AI, big data, and the Internet of Things will be deeply integrated with CNC processing.

- Intelligent CNC systems will possess self – learning, self – optimization, and self – diagnostic functions.

- Human – machine collaboration will become a new production model, enhancing production flexibility and efficiency.

- Networking:

- The industrial Internet will enable the interconnection of CNC equipment.

- Remote monitoring, diagnosis, and maintenance will become the norm.

- Cloud manufacturing will realize the sharing and optimal allocation of manufacturing resources.

- Greening:

- Environment – friendly processing technologies and equipment will be widely applied.

- Resource – saving and environment – friendly manufacturing models will become the mainstream.

- The concept of sustainable development will permeate the entire product life cycle.

V. Selection and Application of CNC Precision Brass Part Processing Technology

5.1 Selection of Processing Technologies for Different Types of Brass Parts

Select appropriate processing technologies according to the structural characteristics and precision requirements of the parts:

- Simple Rotational Parts:

- For shaft – type parts with a small diameter and long length, CNC lathes can be used for processing.

- For disc – type parts with a large diameter and short length, machining centers can be used.

- For simple rotational parts with low – precision requirements, automatic lathes can be used to improve production efficiency.

- Complex Rotational Parts:

- For rotational parts with complex surfaces, turning centers can be used to achieve multiple functions such as turning, milling, and drilling.

- For complex rotational parts with high – precision and good surface – quality requirements, five – axis linkage machining centers can be used.

- For mass – produced complex rotational parts, special production lines can be used to improve production efficiency and quality stability.

- Non – rotational Parts:

- For planar parts, machining centers or gantry milling machines can be used.

- For cavity – groove parts, machining centers or electrical discharge machining can be used.

- For sheet – type parts, stamping processes such as blanking and bending can be combined with CNC processing to complete precision features.

- Precision Small Parts:

- For micro – parts, precision machining centers or micro – processing equipment can be used.

- For high – precision small parts, slow – wire electrical discharge machining can be used.

- For mass – produced small parts, Swiss – type automatic lathes can be used to improve production efficiency and precision.

5.2 Processing Characteristics of Brass Parts in Different Application Fields

Different application fields have varying requirements for brass parts, leading to differences in processing techniques:

- Electronics and Electrical Field:

- Brass parts used in the electronics and electrical industry typically require good electrical and thermal conductivity, and materials like H68 brass are commonly employed.

- Common brass parts in this field include sockets, electrical connectors, and conductive contacts.

- Processing characteristics: High precision requirements, small dimensions, good surface quality requirements. Processes such as precision CNC machining, stamping, and electroplating are often used.

- Automotive and Aerospace Fields:

- Brass parts for automotive and aerospace applications demand high strength, high toughness, and excellent corrosion resistance, with special brass alloys being frequently utilized.

- Common automotive and aerospace brass parts include radiator cores and automotive engine components.

- Processing characteristics: High precision requirements, high reliability requirements, large production volumes. Processes like precision casting, forging, and CNC machining are often adopted.

- Decoration and Crafts Field:

- Brass parts for decoration and crafts need to be aesthetically pleasing and corrosion – resistant, and ordinary or special brass alloys are often selected.

- Common brass parts in this field include sculptures, ornaments, and jewelry.

- Processing characteristics: Complex shapes and high surface quality requirements. Processes such as casting, forging, CNC machining, and surface treatment are frequently used.

- Machinery and Equipment Field:

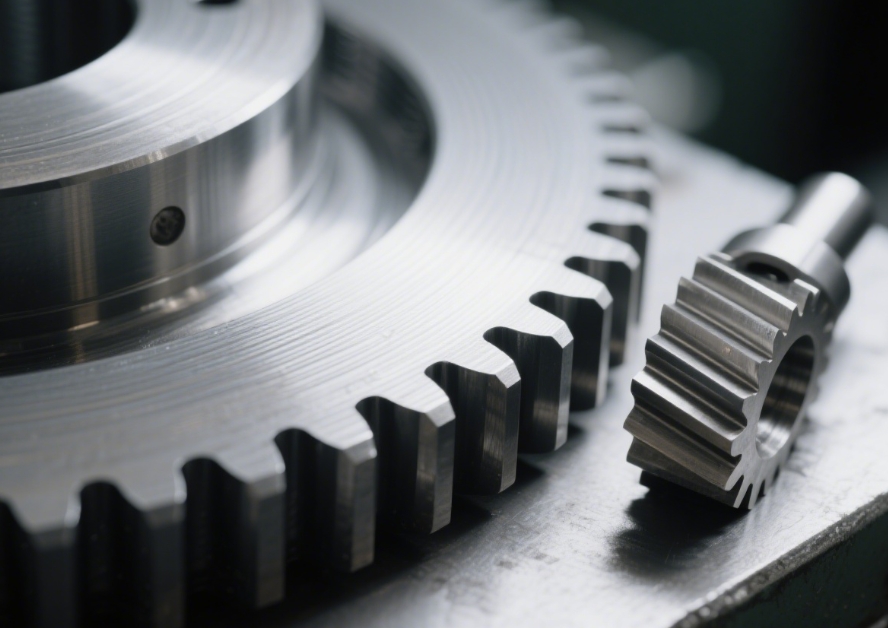

- Brass parts for machinery and equipment require high strength, wear resistance, and corrosion resistance, and high – strength brass materials are often used.

- Common brass parts in this field include bearings, gears, and valves.

- Processing characteristics: High precision requirements, large dimensions, small production volumes. Processes such as casting, forging, and CNC machining are often used.

5.3 Innovation and Future Development Directions of Processing Techniques

With the continuous advancement of technology, the processing technology for CNC precision brass parts is also constantly innovating:

- Hybrid Manufacturing Technology:

- Hybrid manufacturing combines additive manufacturing with traditional subtractive manufacturing or forming technologies to optimize part production.

- Additive Manufacturing + CNC Processing: First, generate near – net – shaped parts through additive manufacturing, and then complete the final shaping through precision machining.

- Casting + Additive Manufacturing: Utilize additive manufacturing to achieve complex internal structures while obtaining the main material through casting.

- Forging + Additive Manufacturing: Use additive manufacturing on forged pre – forms to enhance mechanical properties while reducing material waste.

- Intelligent Manufacturing Model:

- Digital Workshop: Integrate CNC processing equipment, logistics systems, and information systems to achieve digital management.

- Flexible Production Line: Through modular design and rapid change – over technology, achieve multi – variety, small – batch production.

- Smart Factory: Leverage technologies such as AI, the Internet of Things, and big data to achieve intelligent management and optimization of the production process.

- New Processing Techniques:

- Laser – Assisted Machining: Use laser to pre – heat materials, reducing cutting force and cutting heat, thereby improving processing efficiency and quality.

- Ultrasonic Vibration Machining: Superimpose ultrasonic vibration during traditional cutting to reduce cutting force and improve surface quality.

- Electrochemical Machining: Employ electrochemical principles for precision machining, suitable for high – hardness and high – toughness materials.

- Development Directions of Processing Techniques:

- Developing towards higher precision, higher efficiency, and greater flexibility.

- Developing towards green manufacturing, intelligent manufacturing, and service – type manufacturing.

- Developing towards multi – disciplinary intersection and multi – technology integration.

VI. Conclusions and Suggestions

6.1 Comprehensive Evaluation of CNC Precision Brass Part Processing Technology

The processing technology for CNC precision brass parts has the following advantages:

- High processing precision: CNC machining can achieve micron – level or even higher processing precision, meeting the needs of various high – precision parts.

- Wide processing range: CNC machining can complete the processing of various complex shapes, including planes, curves, cavities, and hole systems.

- High processing efficiency: CNC machining has a high degree of automation and can operate continuously for 24 hours, improving production efficiency.

- High material utilization rate: Compared with traditional processes such as casting and forging, CNC machining has a high material utilization rate, reaching over 90%.

- Good quality stability: The CNC machining process is stable, resulting in consistent product quality and a low scrap rate.

- Strong adaptability: CNC machining can quickly adjust the machining program according to design changes, making it suitable for multi – variety, small – batch production.

At the same time, the processing technology for CNC precision brass parts also has some limitations:

- High equipment investment: CNC machine tools are expensive, resulting in a large initial investment.

- High technical requirements: CNC machining requires professional programming and operating personnel, with a high technical threshold.

- Processing cost related to batch size: For large – scale production, the processing cost of CNC machining is relatively high, and it is less cost – effective than dedicated production lines.

- Limited processing efficiency for some parts: For certain parts with simple shapes, the processing efficiency of CNC machining is lower than that of traditional processing methods.

6.2 Suggestions for Selecting Appropriate Processing Techniques

Select appropriate processing techniques based on part characteristics and production requirements:

- Select according to part precision requirements:

- For parts with high – precision and high – surface – finish requirements, choose CNC precision machining.

- For parts with general precision requirements, traditional processing methods such as stamping and casting can be selected.

- For parts with special precision requirements, multiple processing techniques can be combined, such as casting + CNC machining.

- Select according to part complexity:

- For parts with complex shapes, CNC machining has obvious advantages.

- For parts with simple shapes, traditional processing methods may be more cost – effective and efficient.

- For parts with special structures, such as deep cavities, thin – walled parts, and fine features, suitable special processing methods should be chosen.

- Select according to production volume:

- For single – piece and small – batch production, CNC machining is the best choice.

- For medium – batch production, consider combining CNC machining with special tooling to improve efficiency and reduce costs.

- For large – batch production, use dedicated production lines to improve production efficiency and quality stability.

- Select according to material characteristics:

- For brass materials with higher hardness, choose appropriate tool materials and processing techniques.

- For free – cutting brass materials, high – speed cutting processes can be used to improve processing efficiency.

- For brass materials with special performance requirements, such as high electrical conductivity and high thermal conductivity, choose appropriate processing techniques to avoid affecting material properties.

6.3 Suggestions for the Future Development of CNC Precision Brass Part Processing

To promote the development of CNC precision brass part processing technology, the following suggestions are put forward:

- Strengthen basic research:

- Strengthen research on the cutting mechanism of brass materials to provide theoretical support for process optimization.

- Research new tool materials and coating technologies to improve tool life and processing efficiency.

- Research precision measurement technologies to ensure high – precision processing.

- Promote technological innovation:

- Promote the application of new technologies such as AI, big data, and the Internet of Things in CNC machining.

- Develop new processing techniques and equipment to improve processing precision and efficiency.

- Develop green manufacturing technologies to reduce energy consumption and environmental pollution.

- Facilitate industrial upgrading:

- Promote the transformation of traditional processing enterprises towards intelligent manufacturing.

- Strengthen industry – university – research cooperation to facilitate the transformation of scientific and technological achievements.

- Cultivate professional talents to improve the overall technical level of the industry.

- Enhance international cooperation:

- Introduce advanced foreign technologies and equipment to improve domestic processing levels.

- Participate in the formulation of international standards to enhance international discourse power.

- Promote Chinese CNC processing technologies and equipment to the international market.

In conclusion, the processing technology for CNC precision brass parts is a crucial technology indispensable in modern manufacturing. With the continuous progress and innovation of technology, CNC precision brass part processing will develop towards higher precision, higher efficiency, and greater environmental friendliness, providing high – quality and high – performance brass parts for various industries and promoting industrial upgrading and development.