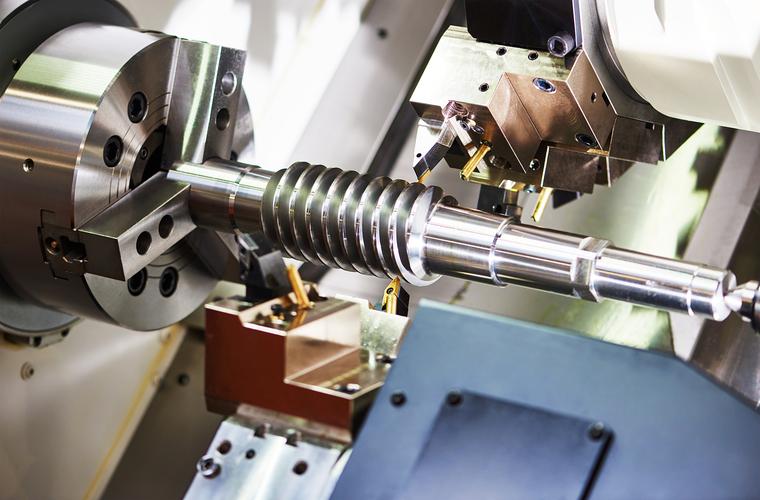

Core Cognition: Threads Are More Than Grooves—They’re Mechanical Connections

- Traditional Threading: A worker manually feeds the tool, adjusting speed by hand—one wrong move, and the thread is scrap. For a batch of 100 M20 bolts, rejection rates often hit 15%.

- CNC Threading: The system calculates every variable (depth, pitch, tool wear) automatically. Rejection rates plummet to 0.5% (Source: 2025 CNC Precision Machining Report), and a single operator can oversee 3-4 machines.

Core Technologies: The Silent Symphony of Codes and Tools

A. Key G-Codes: The Conductors of Thread Forming

|

G-Code

|

Core Function

|

Emotional Resonance (The Craftsman’s Take)

|

|

G76

|

“The Precision Maestro”—Automatic multi-pass threading with incremental depth reduction. Calculates the number of passes based on thread pitch and depth to avoid tool overload.

|

“I used to dread threading 4140 steel until I learned G76. It doesn’t rush—starts with a light cut, eases into deeper ones. Saved me from breaking a $150 carbide tool on a Friday evening.”

|

|

G32

|

“The Flexible Artist”—Single-pass threading for custom profiles (e.g., taper threads, multi-start threads). Requires manual programming of each pass depth.

|

“When a client needed a 3-start thread for a high-speed valve, G32 was my only friend. It let me tweak each pass like a potter shaping clay—no ‘one-size-fits-all’ constraints.”

|

B. Tool Selection: The Right “Pen” for the Job

|

Tool Type

|

Material Match

|

Cutting Speed (Vc)

|

Craftsman’s Insight

|

|

Carbide (TiAlN Coated)

|

Steel (45#), Stainless Steel (304)

|

100-120 m/min

|

“TiAlN coating laughs at heat. I’ve run it on 304 stainless for 8 hours straight—still cuts clean, no built-up edge.”

|

|

High-Speed Steel (HSS)

|

Aluminum (6061), Brass

|

30-50 m/min

|

“HSS is softer, but it’s forgiving. Great for aluminum—doesn’t leave the ‘burrs’ carbide sometimes does. Cheaper, too—perfect for small batches.”

|

|

Thread Forming Tool

|

Aluminum (7075), Copper

|

80-100 m/min

|

“Forming tools don’t cut—they reshape metal. No chips, no mess. Used one for a medical implant’s thread—surface finish Ra=0.4μm, smoother than a polished coin.”

|

Practical Case: Machining M20×2 Threads on 45# Steel Shafts

Step 1: The Dreaded “What Ifs” (Pre-Machining Checks)

- Material Prep: The shafts arrive with a rough turned finish (φ25.5mm)—we need to turn them to φ20mm first (thread major diameter). I always measure 3 points on the shaft to ensure it’s not oval—one oval shaft can ruin an entire batch.

- Tool Setup: Mount a TiAlN-coated carbide thread tool (TN60 insert) in the turret. Check tool runout with a dial indicator—max 0.002mm. Anything more, and the thread will be lopsided.

- Coolant: Fill the tank with 8% emulsified coolant. Threading generates heat—coolant isn’t just “optional”; it’s the difference between a tool that lasts 800 parts and one that dies at 200.

Step 2: Programming—The “Script” for Success

Step 3: The Moment of Truth (Trial Cutting)

Common Nightmares (and How to Wake Up)

1. Thread “Chaos” (Random Pitch Error)

- Cause: Spindle synchronization error (FANUC parameter No. 3741 set too low) or loose belt drive. I once spent 3 hours troubleshooting this—turned out the spindle belt was worn, slipping 1% of the time.

- Solution: Tighten/replace the spindle belt; increase parameter No. 3741 to 500 (improves synchronization). For the next batch, every thread’s pitch was dead-on.

2. Burnt Threads (Discolored, Brittle)

- Cause: No coolant, or cutting speed too high. I did this once with aluminum—forgot to turn on M08. The thread turned black, and the tool edge melted. Cost me $80 and an hour of rework.

- Solution: Double-check M08 in the program; reduce Vc by 20% (for aluminum, from 300 m/min to 240). Coolant isn’t just for the tool—it’s for the thread’s integrity.

3. Thread Root Chipping (Steel/Stainless Steel)

- Cause: Tool nose radius too small (0.1mm instead of 0.3mm) or feed rate too high. I had this happen with 4140 steel—chips kept breaking off the thread root, making it useless.

- Solution: Switch to a 0.3mm nose radius tool; reduce F by 15% (from 2mm/rev to 1.7mm/rev). The root became smooth, no more chipping.

Q&A: The Wisdom of the Shop Floor

Q1: “I’m a beginner—how do I stop breaking thread tools?”

- My Answer: Slow down. Start with 70% of the recommended speed (e.g., 1050 r/min instead of 1500 for steel). And listen to the machine—if it’s making a high-pitched squeal, stop. That’s the tool screaming for help. I broke 12 tools my first month; now I break 1 every 6 months. It’s not skill—it’s respect for the tool.

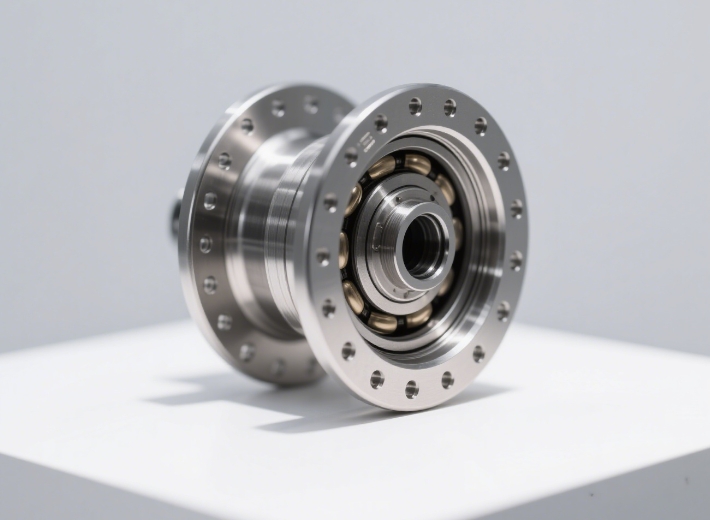

Q2: “Why does my thread fit the gauge but leak when used in a pipe?”

- My Answer: Gauges check pitch and diameter, not “roundness.” If your spindle runout is >0.003mm, the thread will be oval—great for gauges, bad for sealing. I had a client with this issue; we calibrated the spindle, and the leaks stopped. Threads aren’t just about “fitting”—they’re about “sealing” or “holding.”

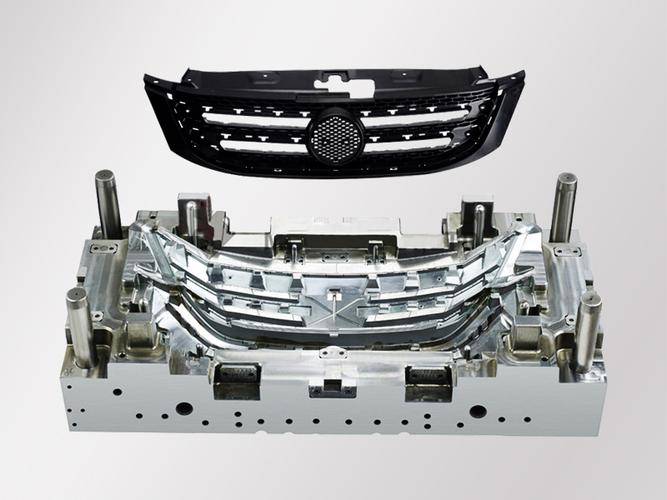

Q3: “Is it worth investing in thread forming tools?”

- My Answer: If you’re machining aluminum or copper (soft materials), yes. No chips mean no cleanup, and the thread is stronger (formed, not cut). I use them for automotive parts—cycle time down by 20%, rejection rate near zero. But for hard steel? Stick to cutting tools—forming tools will wear out fast.