Table of Contents

- Material Composition and Classification

- Mechanical Properties Comparison

- Machining Performance Analysis

- Surface Treatment Characteristics

- Corrosion Resistance Performance

- Weight and Density Differences

- Cost-Benefit Analysis

- Application Field Distribution

- Welding Performance Comparison

- Heat Treatment Effects

- Aesthetics and Texture

- Environmental and Sustainability

- Frequently Asked Questions

Material Composition and Classification

Main Aluminum Alloy Series Classification

- Composition Features: Aluminum content over 99.00%

- Representative Grades: 1050, 1060, 1100

- Key Characteristics: High purity, excellent corrosion resistance, good electrical and thermal conductivity

- Composition Features: Copper as the main alloying element

- Representative Grades: 2024, 2017

- Key Characteristics: High strength, good fatigue performance

- Composition Features: Magnesium as the main alloying element

- Representative Grades: 5052, 5083, 5754

- Key Characteristics: Excellent corrosion resistance, good weldability

- Composition Features: Magnesium and silicon as main alloying elements

- Representative Grades: 6061, 6063, 6082

- Key Characteristics: Medium strength, good machinability

- Composition Features: Zinc as the main alloying element

- Representative Grades: 7075, 7050, 7475

- Key Characteristics: Ultra-high strength, aerospace-grade material

Chemical Composition Comparison Table

|

Alloy Grade

|

Si

|

Fe

|

Cu

|

Mn

|

Mg

|

Cr

|

Zn

|

Ti

|

Al

|

|

6061-T6

|

0.4-0.8

|

0.7

|

0.15-0.4

|

0.15

|

0.8-1.2

|

0.04-0.35

|

0.25

|

0.15

|

Balance

|

|

7075-T6

|

0.4

|

0.5

|

1.2-2.0

|

0.3

|

2.1-2.9

|

0.18-0.28

|

5.1-6.1

|

0.2

|

Balance

|

|

5052-H32

|

0.25

|

0.4

|

0.1

|

0.1

|

2.2-2.8

|

0.15-0.35

|

0.1

|

–

|

Balance

|

|

2024-T3

|

0.5

|

0.5

|

3.8-4.9

|

0.3-0.9

|

1.2-1.8

|

–

|

0.25

|

0.15

|

Balance

|

|

6063-T5

|

0.2-0.6

|

0.35

|

0.1

|

0.1

|

0.45-0.9

|

0.1

|

0.1

|

0.1

|

Balance

|

Mechanical Properties Comparison

Key Mechanical Properties Comparison

|

Alloy Grade

|

Tensile Strength (MPa)

|

Yield Strength (MPa)

|

Elongation (%)

|

Hardness (HB)

|

Fatigue Strength (MPa)

|

|

6061-T6

|

310

|

276

|

12

|

95

|

145

|

|

7075-T6

|

572

|

503

|

11

|

150

|

230

|

|

5052-H32

|

232

|

193

|

15

|

68

|

97

|

|

2024-T3

|

470

|

325

|

20

|

120

|

185

|

|

6063-T5

|

207

|

172

|

8

|

65

|

90

|

Performance Characteristics Analysis

- Highest Tensile Strength: Reaching 572MPa, 1.5 times that of ordinary steel

- Excellent Yield Strength: 503MPa, suitable for heavy-load structural components

- Outstanding Fatigue Strength: 230MPa, ideal for dynamic load applications

- Application Scenarios: Aerospace structural components, high-strength connectors

- Well-Balanced Properties: Good balance of strength, ductility, and machinability

- Cost-Effective: Medium strength with moderate cost

- Widely Applicable: General structural components, mechanical parts, automotive accessories

- High Elongation: 15%, suitable for forming processes

- Moderate Strength: 232MPa, suitable for non-structural components

- Excellent Corrosion Resistance: Preferred choice for marine environments

- Excellent Fatigue Strength: 185MPa, suitable for cyclic loading

- Highest Elongation: 20%, good formability

- High Strength-to-Weight Ratio: Ideal for aerospace applications

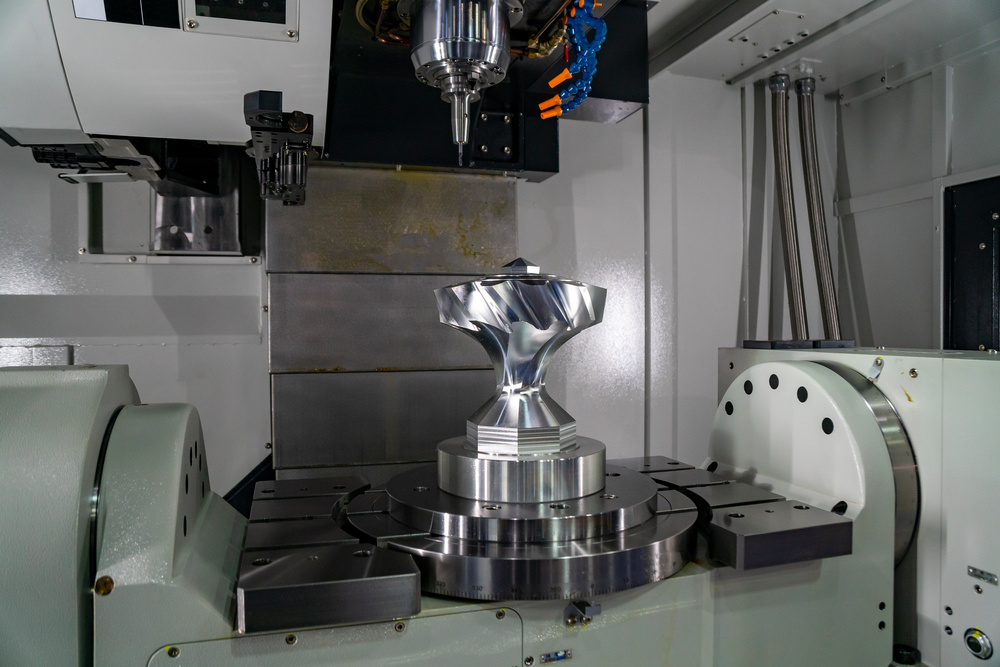

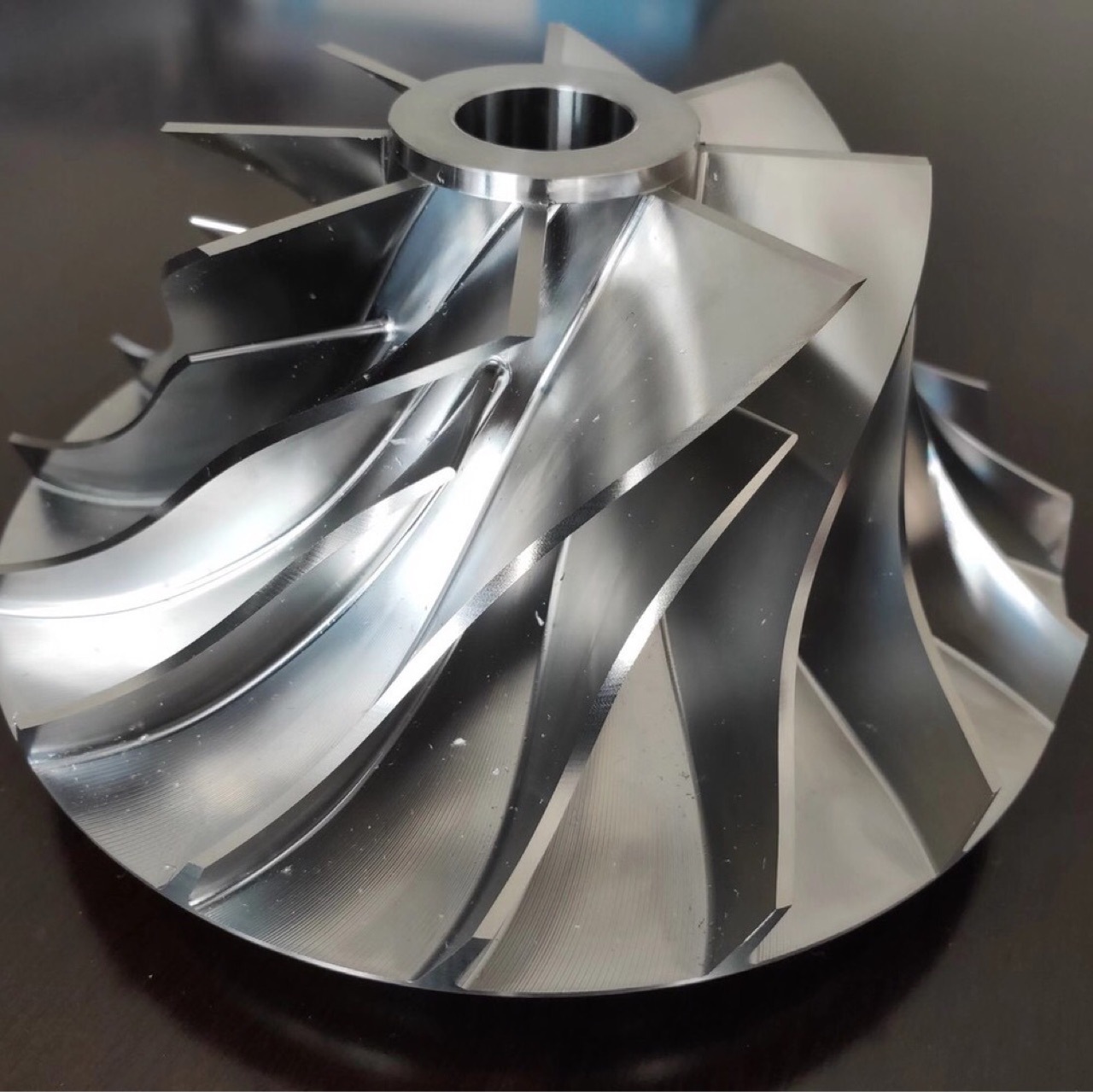

Machining Performance Analysis

Machining Performance Evaluation Metrics

|

Alloy Grade

|

Cutting Performance

|

Drilling Performance

|

Milling Performance

|

Surface Finish

|

Machining Efficiency

|

|

6061-T6

|

★★★★☆

|

★★★★☆

|

★★★★☆

|

★★★★☆

|

★★★★☆

|

|

7075-T6

|

★★★☆☆

|

★★★☆☆

|

★★★☆☆

|

★★★★☆

|

★★★☆☆

|

|

5052-H32

|

★★★☆☆

|

★★★★☆

|

★★★☆☆

|

★★★★☆

|

★★★☆☆

|

|

2024-T3

|

★★★☆☆

|

★★★☆☆

|

★★★☆☆

|

★★★★☆

|

★★★☆☆

|

|

6063-T5

|

★★★★★

|

★★★★★

|

★★★★★

|

★★★★★

|

★★★★★

|

Machining Characteristics Analysis

- Low Cutting Resistance: Soft material with minimal tool wear

- Excellent Surface Quality: Easily achieves Ra 1.6 or better surface finish

- High Machining Efficiency: Feed rates can reach2000mm/min or higher

- Suitable for Mass Production: Automotive parts, architectural profiles

- Stable Machining: Smooth cutting process with minimal vibration

- Long Tool Life: 30% less tool consumption compared to high-strength alloys

- Suitable for Precision Machining: Tolerance control within ±0.01mm

- High Cutting Forces: Requires more powerful machine tools

- Rapid Tool Wear: Carbide tools recommended

- High Machining Temperatures: Requires adequate cooling

- Higher Machining Costs: 40-60% higher labor costs than 6061

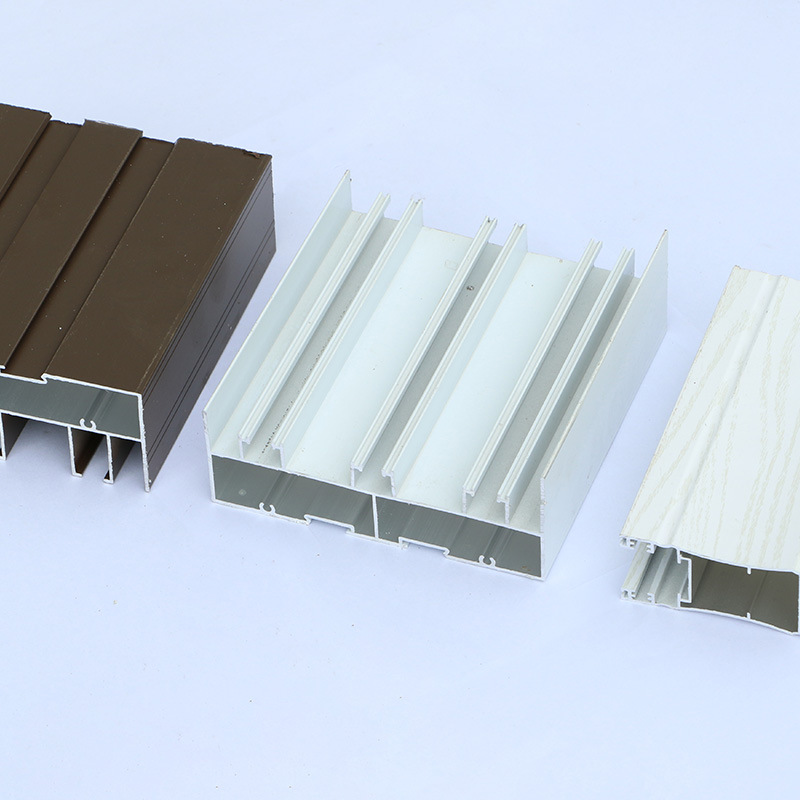

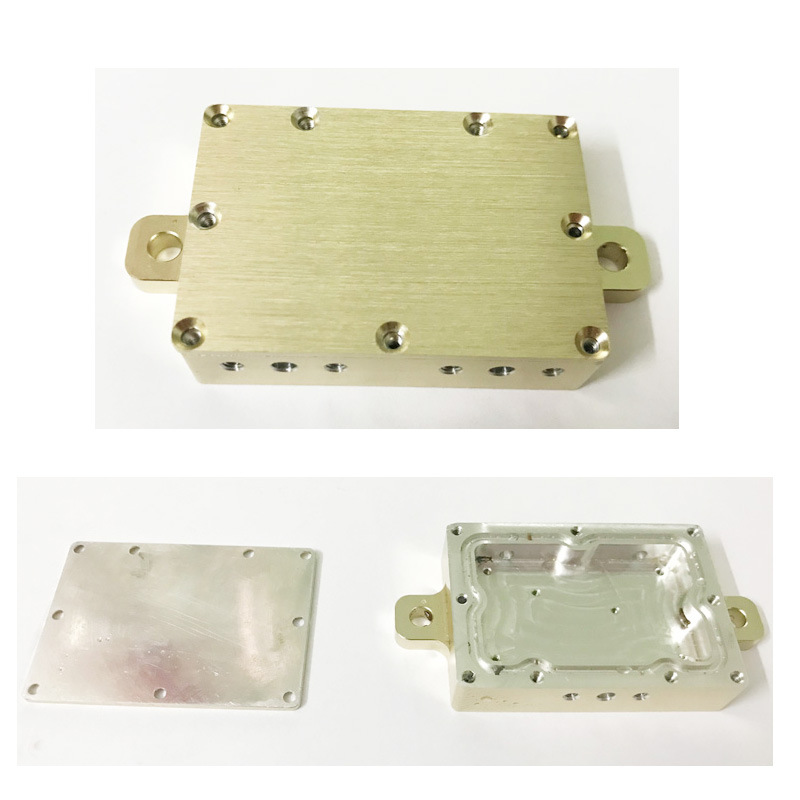

Surface Treatment Characteristics

Main Surface Treatment Process Comparison

|

Surface Treatment Process

|

Applicable Materials

|

Treatment Effect

|

Corrosion Resistance

|

Cost

|

Environmental Friendliness

|

|

Anodizing

|

All aluminum alloys

|

Rich colors, improved hardness

|

★★★★★

|

★★★☆☆

|

★★★☆☆

|

|

Electroplating

|

6061, 2024

|

Bright appearance, good wear resistance

|

★★★☆☆

|

★★★★☆

|

★★☆☆☆

|

|

Powder Coating

|

All aluminum alloys

|

Various colors, uniform coating

|

★★★★☆

|

★★★☆☆

|

★★★★☆

|

|

Electrophoretic Coating

|

6063, 6061

|

Thin, uniform film

|

★★★★★

|

★★★★☆

|

★★★☆☆

|

|

Chemical Conversion Coating

|

All aluminum alloys

|

Simple, economical base layer

|

★★★☆☆

|

★★☆☆☆

|

★★★☆☆

|

Surface Treatment Effect Analysis

- Best Materials: 6063-T5, with uniform oxide film and bright colors

- Thickness Range: 5-25μm, adjustable according to requirements

- Color Options: Natural, black, gold, and various colors

- Application Cases: Architectural decoration, electronic housings, automotive parts

- Advantages: Uniform coating thickness, wide color selection

- Performance Indicators: Impact resistance, wear resistance, UV resistance

- Environmental Benefits: No solvent emissions, recyclable

- Applicable Scenarios: Outdoor furniture, building facades, appliance housings

- Main Types: Chrome plating, nickel plating, zinc plating

- Performance Features: Bright surface, excellent wear resistance

- Considerations: Higher environmental impact, relatively high cost

- Application Limitations: Mainly for decorative components

Corrosion Resistance Performance

Corrosion Resistance Rating Evaluation

|

Alloy Grade

|

Atmospheric Corrosion

|

Seawater Corrosion

|

Chemical Corrosion

|

Stress Corrosion

|

Corrosion Grade

|

|

6061-T6

|

★★★★☆

|

★★★☆☆

|

★★★☆☆

|

★★★☆☆

|

Grade B

|

|

7075-T6

|

★★★☆☆

|

★★☆☆☆

|

★★☆☆☆

|

★★☆☆☆

|

Grade C

|

|

5052-H32

|

★★★★★

|

★★★★★

|

★★★★☆

|

★★★★☆

|

Grade A

|

|

2024-T3

|

★★★☆☆

|

★★☆☆☆

|

★★☆☆☆

|

★☆☆☆☆

|

Grade C

|

|

6063-T5

|

★★★★☆

|

★★★☆☆

|

★★★☆☆

|

★★★☆☆

|

Grade B

|

Corrosion Protection Measures

- Marine Environments: Priority selection of 5052-H32, followed by 6061-T6

- Industrial Environments: 6061-T6 or 5052-H32 with appropriate surface treatment

- High-Temperature Environments: 2024-T3 requires surface treatment, avoid prolonged exposure

- Anodizing: Improves corrosion resistance by 2-3 times

- Coating Protection: Organic coatings provide long-term protection

- Sealing Treatment: Further enhances performance after anodizing

- Avoid Crevices: Reduce crevice corrosion risks

- Drainage Design: Prevent water accumulation causing localized corrosion

- Material Isolation: Avoid contact corrosion between different metals

Weight and Density Differences

Density and Weight Comparison

|

Material Type

|

Density (g/cm³)

|

Relative Density (vs. Steel)

|

Weight Reduction Ratio

|

Strength-to-Weight Ratio

|

|

6061-T6

|

2.70

|

0.298

|

70.2%

|

114.8

|

|

7075-T6

|

2.81

|

0.310

|

69.0%

|

203.6

|

|

5052-H32

|

2.68

|

0.296

|

70.4%

|

86.6

|

|

2024-T3

|

2.78

|

0.307

|

69.3%

|

169.1

|

|

Carbon Steel

|

7.85

|

1.000

|

0%

|

51.0

|

Lightweight Advantage Analysis

- Significant Weight Reduction: Approximately 70% weight reduction compared to steel

- Fuel Efficiency Improvement: Every 1kg weight reduction saves 300kg fuel annually for aircraft

- Increased Payload Capacity: More effective payload with same weight

- Fuel Consumption Reduction: 10% vehicle weight reduction leads to 6-8% fuel savings

- Performance Improvement: Enhanced acceleration and handling performance

- Emission Reduction: Approximately 5g/km CO₂ emission reduction

- Portability Enhancement: Lighter laptops, mobile phones and other devices

- Heat Dissipation Improvement: Good thermal conductivity aids heat dissipation design

- Aesthetic Appeal: Metal texture enhances product quality

Design Optimization Strategies

- Thin-Wall Design: Reduce wall thickness while ensuring strength

- Hollow Structures: Use hollow profiles to reduce weight

- Topology Optimization: Optimize structural shape using FEA analysis

- Steel to Aluminum: Replace steel with high-strength aluminum alloys in critical areas

- Multi-Material Design: Select most suitable materials for different components

- Functional Integration: Reduce part count for further weight reduction

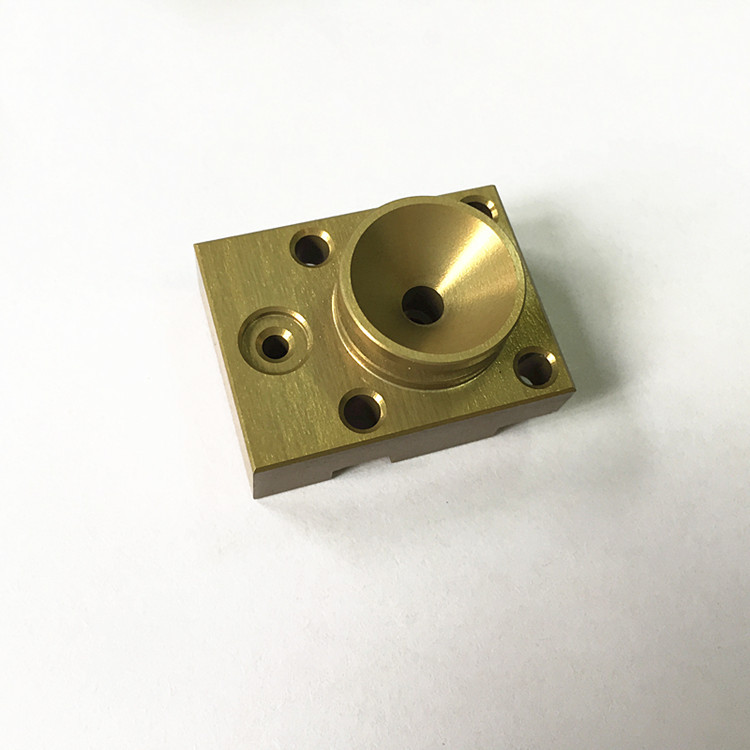

Cost-Benefit Analysis

Material Cost Comparison (2025 Market Prices)

|

Alloy Grade

|

Raw Material Price (RMB/kg)

|

Processing Cost Factor

|

Surface Treatment Cost

|

Comprehensive Cost Index

|

|

6061-T6

|

22-28

|

1.0

|

Medium

|

1.0

|

|

7075-T6

|

55-65

|

1.5

|

Higher

|

2.3

|

|

5052-H32

|

28-35

|

1.1

|

Lower

|

1.2

|

|

2024-T3

|

45-55

|

1.4

|

Higher

|

1.9

|

|

6063-T5

|

18-24

|

0.8

|

Lower

|

0.8

|

Cost Composition Analysis

- Raw Material Cost: 40-60% of total cost

- Processing Cost: 25-40% of total cost

- Surface Treatment: 10-20% of total cost

- Quality Cost: 5-10% of total cost

- Machining Difficulty: Machining cost of 7075 is 1.5 times that of 6061

- Tool Consumption: Tool life reduced by 30-50% for high-strength alloys

- Processing Time: Up to 20-30% difference in machining time for complex parts

Cost-Effectiveness Evaluation

- Balanced Performance: Meets most application requirements

- Moderate Processing Costs: No special equipment or tools required

- Widely Available: Mature technology with sufficient market supply

- Lowest Material Cost: Approximately 20% lower than 6061

- Highest Processing Efficiency: Suitable for mass production

- Simple Surface Treatment: Good oxidation effect with low cost

- Highest Strength: Suitable for high-requirement applications

- Higher Cost: Material price is 2.5 times that of 6061

- Suitable for Critical Components: Applications with high safety factor requirements

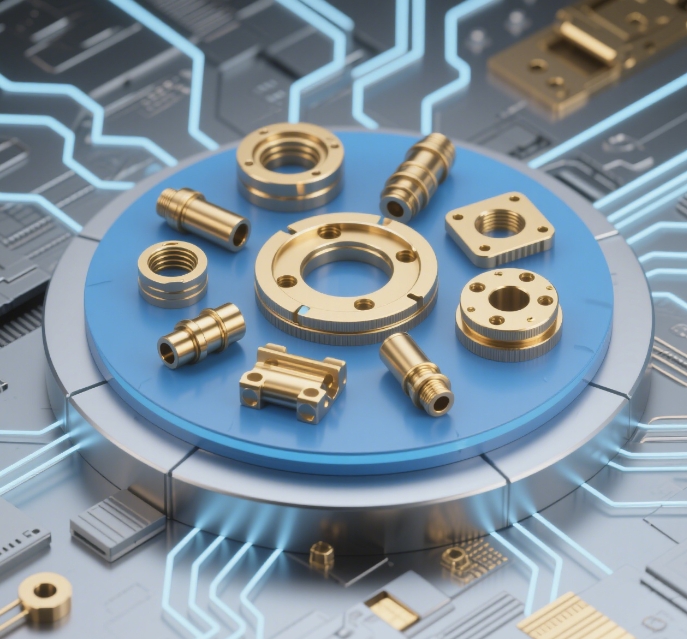

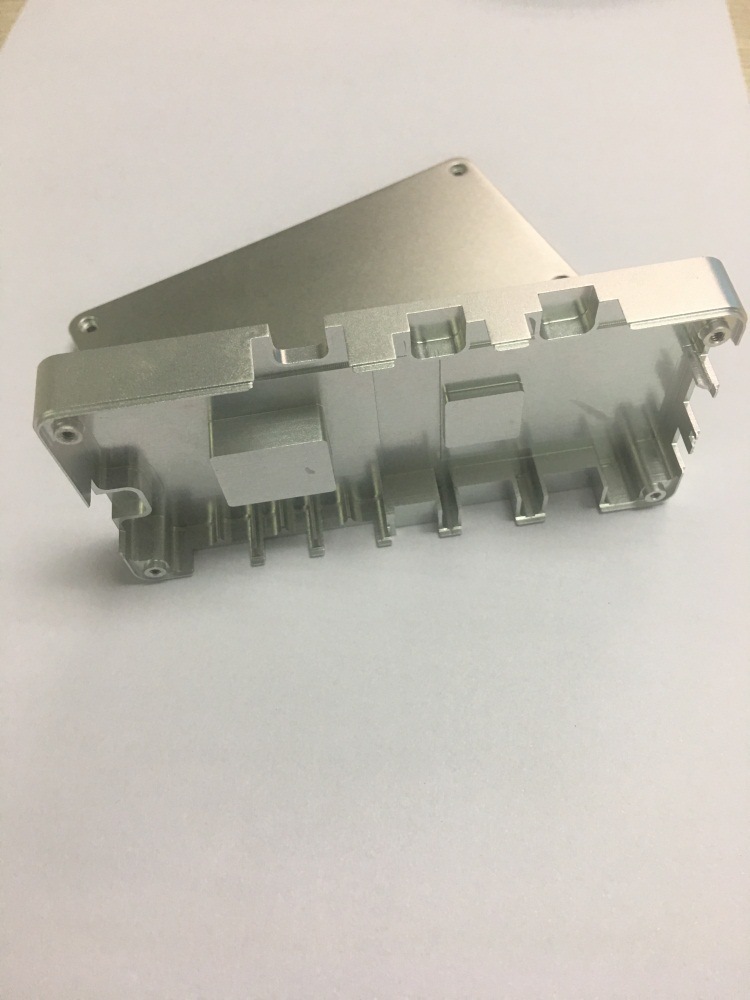

Application Field Distribution

Main Application Field Distribution

|

Application Field

|

Primary Materials

|

Application Ratio

|

Key Requirements

|

Typical Products

|

|

Aerospace

|

7075-T6, 2024-T3

|

65%

|

High strength, lightweight

|

Airframe structures, wings, landing gear

|

|

Automotive

|

6061-T6, 5052-H32

|

45%

|

Lightweight, corrosion resistance

|

Body frames, engine parts, wheels

|

|

Electronic Devices

|

6061-T6, 6063-T5

|

70%

|

Precision machining, appearance

|

Laptop housings, phone frames, heat sinks

|

|

Architectural Decoration

|

6063-T5, 5052-H32

|

80%

|

Corrosion resistance, aesthetics

|

Door/window profiles, curtain walls, decorative materials

|

|

Medical Devices

|

6061-T6, 5052-H32

|

55%

|

Biocompatibility, precision

|

Surgical instruments, equipment frames, wheelchairs

|

|

Sports Equipment

|

7075-T6, 6061-T6

|

60%

|

High strength, lightweight

|

Bicycle frames, golf clubs, mountaineering equipment

|

Industry Application Deep Analysis

- 7075-T6 Most Widely Used: Accounts for 40% of aerospace aluminum alloy usage

- Key Requirements: High strength, fatigue performance, reliability

- Quality Control: Strict quality certification and testing standards

- Development Trend: Moving toward higher strength materials and composites

- Clear Lightweight Trend: Aluminum alloy usage increasing year by year

- Significant Cost Pressure: Mainly uses 6061 and 5052 series

- Process Requirements: Materials suitable for mass production

- Environmental Requirements: Recyclability and sustainability

- Precision Machining Requirements: Tolerance control within ±0.01mm

- High Appearance Quality Requirements: Surface finish and color consistency

- Thermal Performance Important: Good thermal conductivity

- Lightweight Needs: Weight control for portable devices

Emerging Application Fields

- Battery Housings: 5052-H32, good corrosion resistance

- Motor Components: 6061-T6, good heat dissipation performance

- Body Structures: 6061-T6, significant lightweight effect

- Frame Structures: 7075-T6, high strength-to-weight ratio

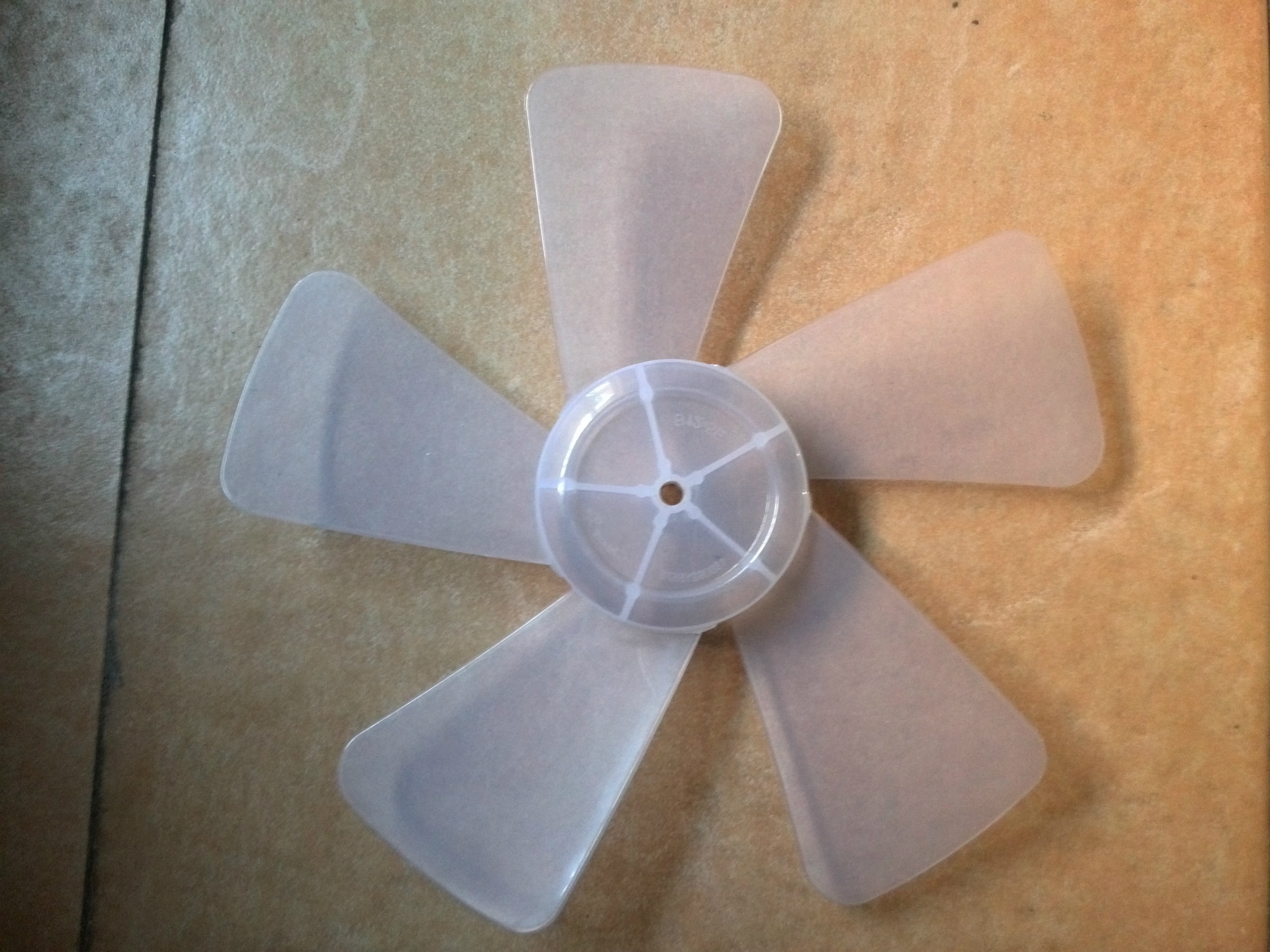

- Propellers: 6061-T6, good balance performance

- Battery Compartments: 5052-H32, excellent corrosion resistance

Welding Performance Comparison

Welding Performance Evaluation

|

Alloy Grade

|

TIG/MIG Welding

|

Resistance Welding

|

Laser Welding

|

Weld Strength Retention

|

Welding Difficulty

|

|

6061-T6

|

★★★★☆

|

★★★☆☆

|

★★★★☆

|

85-90%

|

★★★☆☆

|

|

7075-T6

|

★★★☆☆

|

★★☆☆☆

|

★★★☆☆

|

75-80%

|

★★★★☆

|

|

5052-H32

|

★★★★★

|

★★★★☆

|

★★★★★

|

90-95%

|

★★☆☆☆

|

|

2024-T3

|

★★★☆☆

|

★★☆☆☆

|

★★★☆☆

|

70-75%

|

★★★★☆

|

|

6063-T5

|

★★★★☆

|

★★★☆☆

|

★★★★☆

|

80-85%

|

★★★☆☆

|

Welding Process Characteristics

- Excellent Welding Performance: Stable welding process with minimal porosity

- High Weld Strength: Maintains 90-95% of base material strength

- Good Corrosion Resistance: Excellent corrosion resistance in weld areas

- Recommended Applications: Vessel manufacturing, piping systems, welded structures

- Mature Welding Process: Easily controllable welding parameters

- Stable Weld Quality: Suitable for automated welding

- Simple Post-Treatment: Heat treatment can improve performance

- Widely Applied: Mechanical structures, frames, connectors

- Crack Susceptibility: Requires preheating and slow cooling

- Strict Welding Parameters: High temperature control requirements

- Post-Weld Heat Treatment: Requires artificial aging treatment

- Higher Costs: Requires professional welding technicians

Welding Process Selection

- Applicable Materials: All aluminum alloys, especially suitable for 5052, 6061

- Advantages: Good welding quality, aesthetic weld appearance

- Disadvantages: Lower efficiency, higher cost

- Applicable Materials: 6061, 5052, 6063

- Advantages: High precision, small heat-affected zone

- Disadvantages: High equipment investment, strict fixturing requirements

- Applicable Materials: 5052, 6061 thin sheets

- Advantages: High efficiency, suitable for mass production

- Disadvantages: Relatively lower spot strength

Heat Treatment Effects

Main Heat Treatment Processes

|

Heat Treatment Process

|

Applicable Materials

|

Treatment Temperature (°C)

|

Treatment Time

|

Performance Improvement

|

|

T6 Solution Aging

|

6061, 7075

|

530-540

|

12-24h

|

Significant strength improvement

|

|

T5 Artificial Aging

|

6063

|

175-185

|

6-8h

|

Moderate strength improvement

|

|

T3 Solution Natural Aging

|

2024

|

495-503

|

Natural aging

|

Balanced strength and toughness

|

|

H32 Strain Hardening

|

5052

|

Cold working + stabilization

|

–

|

Strength improvement with retained ductility

|

Heat Treatment Effect Comparison

- Solution Treatment: 530°C for 4-6 hours, water quenching

- Artificial Aging: 175°C for 8 hours

- Performance Improvement: Tensile strength increased from 110MPa to 310MPa

- Hardness Change: From HB 30 to HB 95

- Solution Treatment: 475°C for 2 hours, water quenching

- Artificial Aging: 120°C for 24 hours

- Performance Improvement: Tensile strength increased from 180MPa to 572MPa

- Hardness Change: From HB 50 to HB 150

- Solution Treatment: 495°C for 2 hours, water quenching

- Natural Aging: Room temperature for 4 days

- Performance Characteristics: Balance of high strength and good toughness

- Application Advantages: Excellent fatigue performance

Heat Treatment Considerations

- Temperature Control: ±5°C temperature accuracy requirement

- Time Control: Strict adherence to process timing

- Cooling Rate: Sufficiently fast water quenching

- Distortion Control: Distortion management during heat treatment

- Hardness Testing: Verification of heat treatment effect

- Tensile Testing: Confirmation of mechanical properties

- Metallographic Analysis: Microstructure examination

- Dimensional Inspection: Evaluation of distortion

Aesthetics and Texture

Surface Texture Characteristic Comparison

|

Alloy Grade

|

Surface Gloss

|

Texture 表现

|

Oxidation Effect

|

Coating Adhesion

|

Texture Grade

|

|

6061-T6

|

★★★★☆

|

★★★★☆

|

★★★★☆

|

★★★★☆

|

Grade A

|

|

7075-T6

|

★★★★☆

|

★★★☆☆

|

★★★☆☆

|

★★★☆☆

|

Grade A

|

|

5052-H32

|

★★★★★

|

★★★★★

|

★★★★★

|

★★★★★

|

Grade A+

|

|

2024-T3

|

★★★☆☆

|

★★★☆☆

|

★★★☆☆

|

★★★☆☆

|

Grade B

|

|

6063-T5

|

★★★★★

|

★★★★★

|

★★★★★

|

★★★★★

|

Grade A+

|

Aesthetic Design Advantages

- Highest Surface Gloss: Good natural metallic luster

- Best Oxidation Effect: Uniform oxide film with long-lasting vibrant colors

- Excellent Texture achieve: Good effect with brushing, sandblasting and other textures

- Recommended Applications: High-end decoration, consumer electronics, furniture

- Good Surface Flatness: Suitable for precision appearance parts

- Uniform Oxidation Coloring: Good color consistency

- Cost-Effective: Good balance of appearance performance and cost

- Widely Applied: Architectural decoration, lighting, home appliances

- Good Comprehensive Performance: Balance of appearance and functionality

- High Machining Precision: Suitable for complex appearance designs

- Diverse Surface Treatments: Supports various surface processes

- Flexible Application: Wide range from industrial to consumer products

Surface Treatment Process Effects

- Natural Color: Silver-white, clean and modern

- Black: Deep and stable, high-end atmosphere

- Colored: Rich color options to meet personalized needs

- Hard Anodizing: High surface hardness, good wear resistance

- Brushing: Linear texture, strong technological

- Sandblasting: Matte effect, fine texture

- Polishing: Mirror effect, high-end and exquisite

- Etching: Fine patterns, personalized design

Design Application Recommendations

- Color Matching: Select appropriate surface treatment colors based on product positioning

- Texture Selection: Consider usage environment and tactile needs

- Cost Control: Control costs while meeting appearance requirements

- Process Feasibility: Consider mass production process feasibility

- Tactile Optimization: Impact of surface texture on touch feeling

- Visual Hierarchy: Creating visual hierarchy through surface treatment

- Brand Recognition: Unified surface treatment style strengthens brand image

- Durability Requirements: Surface durability considerations for different usage environments

Environmental and Sustainability

Environmental Performance Evaluation

|

Evaluation Criteria

|

6061-T6

|

7075-T6

|

5052-H32

|

2024-T3

|

6063-T5

|

|

Recyclability Rate

|

★★★★★

|

★★★★☆

|

★★★★★

|

★★★☆☆

|

★★★★★

|

|

Energy Consumption Index

|

★★★★☆

|

★★★☆☆

|

★★★★☆

|

★★★☆☆

|

★★★★★

|

|

Emission Index

|

★★★★☆

|

★★★☆☆

|

★★★★☆

|

★★★☆☆

|

★★★★★

|

|

Toxic Substances

|

★★★★★

|

★★★☆☆

|

★★★★★

|

★★★☆☆

|

★★★★★

|

|

Environmental Grade

|

Grade A

|

Grade B

|

Grade A+

|

Grade B

|

Grade A+

|

Sustainability Analysis

- High Recycling Rate: Aluminum alloy recycling rate exceeds 95%

- Energy Savings: Recycling aluminum saves over 95% energy compared to primary aluminum

- Emission Reduction: 90% reduction in CO₂ emissions during recycling

- Circular Economy: Infinite recycling with almost no quality loss

- 6063-T5 Most Environmentally Friendly: Fewer alloying elements, simpler production process

- 5052-H32 Relatively Environmentally Friendly: Main alloying element is magnesium with minimal environmental impact

- 7075-T6 More Complex: Contains zinc, copper and other elements, more complex recycling process

- 2024-T3 Requires Attention: Higher copper content requires separation during recycling

- Long Service Life: Aluminum alloy products have long service life, reducing replacement frequency

- Low Maintenance: Good corrosion resistance results in minimal environmental impact during maintenance

- Recyclable: Products can be fully recycled after end of service life

- Pollution-Free: No harmful substances released during usage

Environmental Design Recommendations

- Priority Selection: Environmentally friendly materials such as 6063-T5, 5052-H32

- Reduced Usage: Minimize use of materials with high environmental impact like 7075-T6, 2024-T3

- Consider Full Life Cycle: Complete environmental impact from production to recycling

- Compliance with Standards: Select materials meeting environmental certifications

- Modular Design: Facilitate disassembly and recycling

- Material Simplification: Reduce mixed use of different materials

- Lightweight Design: Reduce material consumption and transportation energy consumption

- Long-Life Design: Extend product service life

- Marking Design: Clear material identification for easy sorting and recycling

- Connection Design: Easy-to-disassemble connection methods

- Material Separation: Avoid permanent joining of different materials

- Recycling Process: Consider recycling process convenience during design

Frequently Asked Questions

Q1: How to select the appropriate aluminum alloy material for CNC machining?

- Strength Requirements: Choose 7075-T6 for high requirements, 6061-T6 for general requirements

- Machining Difficulty: Choose 6063-T5 for mass production, 6061-T6 for precision machining

- Corrosion Resistance: Choose 5052-H32 for marine environments, 6061-T6 for industrial environments

- Cost Budget: Choose 6063-T5 for economy, 6061-T6 for cost-effectiveness

- Surface Requirements: Choose 5052-H32 or 6063-T5 for appearance parts

Q2: What are the main differences between 6061 and 7075 aluminum alloys?

- Strength Difference: 7075-T6 has a tensile strength of 572MPa, 1.8 times that of 6061-T6 (310MPa)

- Weight Difference: 7075 has a density of 2.81g/cm³, slightly heavier than 6061 (2.70g/cm³) by about 4%

- Machining Performance: 6061 has good machining performance, while 7075 is more difficult to machine

- Cost Difference: 7075 material price is about 2.5 times that of 6061

- Application Fields: 6061 is versatile, 7075 is suitable for high-strength requirements

Q3: What is the best surface treatment option for aluminum alloys after machining?

- Best Cost-Effectiveness: Anodizing, suitable for most applications

- Best Corrosion Resistance: Hard anodizing, suitable for harsh environments

- Best Appearance Effect: Powder coating, with wide color selection

- Best Conductivity: Conductive oxidation, suitable for electronic applications

- Best Wear Resistance: Hard chrome plating, suitable for moving parts

Q4: What issues need attention when welding aluminum alloys?

- Material Cleaning: thoroughly clean surface oil and oxide film before welding

- Gas Protection: Use high-purity argon protection with flow rate 15-25L/min

- Preheating Control: Preheating to 100-200°C required for thick plate welding

- Filler Material: Select matching welding wire such as ER4043, ER5356

- Post-Treatment: Stress relief treatment required for important structures

Q5: How to improve the surface quality of aluminum alloy CNC machining?

- Tool Selection: Use ultra-fine grain carbide tools or diamond tools

- Cutting Parameters: High spindle speed, appropriate feed rate to avoid built-up edge

- Cooling and Lubrication: Use special aluminum alloy cutting fluid with sufficient cooling

- Machining Sequence: Reasonable arrangement of roughing → semi-finishing → finishing

- Vibration Control: Ensure machine tool rigidity and reduce machining vibration

Q6: How to test the properties of aluminum alloys after heat treatment?

- Hardness Testing: Brinell or Vickers hardness testing for quick evaluation

- Tensile Testing: Determine tensile strength, yield strength and elongation

- Impact Testing: Evaluate material toughness and impact resistance

- Metallographic Analysis: Check if microstructure meets standard requirements

- Dimensional Inspection: Evaluate distortion during heat treatment

Q7: What considerations are needed for aluminum alloy material inventory management?

- Environmental Control: Dry and well-ventilated warehouse, avoid humid environment

- Surface Protection: Surface protection for finished parts to avoid scratches

- Classified Storage: Separate storage of different grades and tempers

- First-In First-Out: Use according to warehousing time sequence, avoid long-term storage

- Regular Inspection: Regularly check surface condition and identification of inventory materials

Q8: What are the usage limitations of aluminum alloys in high-temperature environments?

- Temperature Limit: General aluminum alloys have long-term service temperature not exceeding 150°C

- Strength Reduction: Strength decreases significantly with increasing temperature

- Accelerated Oxidation: Oxidation rate accelerates at high temperatures, requiring protective measures

- Creep Phenomenon: Long-term high-temperature loading causes creep deformation

- Material Selection: Special high-temperature aluminum alloys should be selected for high-temperature applications

Summary and Recommendations

Material Selection Recommendations

- Balanced comprehensive performance, suitable for most application scenarios

- Good machining performance without special equipment requirements

- Moderate cost with good cost-effectiveness

- Recommended applications: General mechanical parts, automotive accessories, electronic equipment

- Highest strength, suitable for high-requirement structural components

- Lightweight with excellent strength-to-weight ratio

- Higher cost, suitable for critical components

- Recommended applications: Aerospace, sports equipment, high-end equipment

- Lowest cost, suitable for mass production

- Best machining performance with high production efficiency

- Good surface treatment effect with high appearance quality

- Recommended applications: Architectural profiles, decorative materials, high-volume parts

- Best corrosion resistance, suitable for harsh environments

- Excellent welding performance, suitable for welded structures

- Good surface texture, suitable for appearance parts

- Recommended applications: Marine equipment, outdoor products, food machinery

Application Strategy Recommendations

- Fully understand the characteristics and application limitations of various aluminum alloys

- Comprehensive consideration of performance, cost, machining, environmental and other factors

- Conduct necessary material testing and verification

- Develop reasonable surface treatment and assembly processes

- Select appropriate machining equipment and tools

- Develop optimized machining process parameters

- Strictly control heat treatment and surface treatment quality

- Establish comprehensive quality inspection system

- Understand material usage limitations and maintenance requirements

- Develop reasonable maintenance and maintenance plans

- Establish product lifecycle management system

- Consider recycling and reuse after product end-of-life

- ASTM B209 – Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate

- ISO 209 – Aluminum and aluminum alloys — Sheet, strip and plate

- GB/T 3880 – Aluminum and aluminum alloy rolled plates, sheets and strips

- EN 485 – Aluminum and aluminum alloys — Sheet, strip and plate