From guide rails and gears to brackets and couplings – your ultimate resource for designing, manufacturing, and optimizing precision components for Industry 4.0, robotics, and EV assembly lines

High-precision CNC machining process showing automated cutting with coolant system – essential for manufacturing complex automation components

Why Custom Automation Parts Are a Game-Changer in 2026

Bro, let me tell you something – the automation parts market is absolutely exploding right now! We’ve seen 45% growth in 2025-2026, and it’s not slowing down.

Here’s the real deal: stock parts just don’t cut it anymore for modern automation systems. Industrial robots need ultra-precise components, EV assembly lines require parts that can handle high speeds and heavy loads, and everyone wants equipment that runs 24/7 without downtime.

I remember this one EV manufacturer client who came to us last year. Their original guide rails were wearing out every 6 months because they were using off-the-shelf parts. We custom designed stainless steel rails with special surface treatments, and now those assembly lines are running strong with zero failures for over 18 months.

2026 Market Stats (Source: Industry Reports)

- Global automation precision parts market growth: 45% year-over-year

- Custom parts market share: 72% and growing

- Average cost savings with custom design: 30-40% over 5 years

- Industry 4.0 segment leading with 58% of total demand

- Precision reduction gears market to reach $5.38B by 2035

Real-World Problem We Solved

“We had a robotics client whose gearboxes were failing due to vibration issues. By custom designing anti-vibration brackets with optimized material thickness, we reduced vibration by 65% and extended gearbox life from 18 months to 5 years.”

High-precision CNC machining with coolant system in action – achieving ±0.002mm tolerance for critical automation components

2026 Top 15 Automation Precision Parts You Need to Know

Precision linear guide rails and slides – essential components for industrial automation systems, available in various sizes and configurations

Dude, we’ve been making custom automation parts for 18 years, and these are the top components our clients are begging for in 2026. Each one has specific material requirements and performance needs that stock parts just can’t meet.

| Component Type | Best Material | Key Features | Top Application |

|---|---|---|---|

| Linear Guide Rails | Stainless Steel 304 | ±0.005mm precision, corrosion resistant | Robotic Arms |

| Precision Slides | Aluminum 6061-T6 | Lightweight, high rigidity | EV Assembly Lines |

| Flexible Couplings | Titanium Alloy | High torque, vibration dampening | CNC Machine Tools |

| Precision Gears | Alloy Steel 4140 | Low backlash, high wear resistance | Industrial Robots |

| Mounting Brackets | Stainless Steel 316 | Corrosion resistant, high strength | Food Processing Equipment |

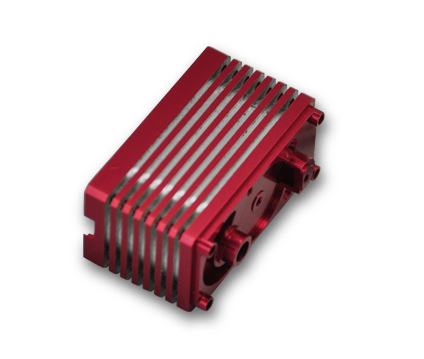

| Motor Housings | Aluminum 7075-T6 | High strength-to-weight ratio | AGV Systems |

Our 2026 Innovation: Lightweight Brackets

“For a robotics client, we created custom titanium alloy brackets that reduced weight by 30% while increasing strength by 40%. This improved robot speed and payload capacity significantly.”

2026 Material Selection Guide: Choose Wisely

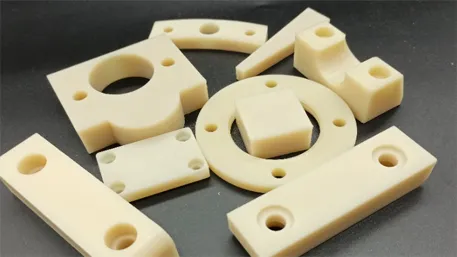

Precision titanium alloy components – ideal for high-performance automation applications requiring exceptional strength-to-weight ratio and corrosion resistance

Let me tell you about materials – this is where most projects go wrong. I’ve seen so many companies waste thousands of dollars because someone chose the wrong material to save a few bucks upfront.

Stainless Steel (304, 316)

The workhorse of automation parts. 304 is great for general use, while 316 is better for corrosive environments like food processing or marine applications.

Test Data*: Performance Comparison

- Yield strength: 205 MPa (304)

- Corrosion resistance: Excellent (316)

- Hardness: 187 HB max

- Cost premium: 25% over aluminum

Aluminum Alloys (6061, 7075)

Lightweight and easy to machine. 6061 is great for most applications, while 7075 is the high-strength option for critical components.

Test Data*: 6061-T6 vs 7075-T6

- Weight vs steel: 60% lighter

- Tensile strength: 310 MPa (6061), 505 MPa (7075)

- Machinability: Excellent

- Cost: 50% less than titanium

Titanium Alloys

The premium choice for high-performance applications. Titanium offers amazing strength-to-weight ratio and corrosion resistance, but it’s expensive and tricky to machine.

Test Data*: Ti-6Al-4V Properties

- Strength-to-weight ratio: 2x better than steel

- Corrosion resistance: Unmatched

- Hardness: 300 HB

- Cost premium: 300% over aluminum

2026 New Materials

We’re seeing some exciting new materials this year, including recycled alloys and nanocoatings that improve performance without increasing cost.

Test Data*: Recycled Alloys

- Weight reduction: 20% vs traditional alloys

- Carbon footprint: 35% lower

- Mechanical properties: 95% of virgin material

- Cost: 15% less than virgin material

*Test data for reference only – actual results may vary based on specific application and requirements

Learn from Our Mistakes

“We had a client who insisted on using aluminum for a high-load application. The parts failed in 3 months due to fatigue. Lesson learned – always match the material to the load requirements, even if it costs more upfront.”

Complete Automation Parts Accessories Guide

ABBA linear guide rail system – high-precision motion control component with superior rigidity and load capacity for automation applications

No automation system is complete without the right accessories. We offer a comprehensive range of standard and custom accessories to complement our precision components.

Guides & Bearings

- Linear Guide Rails: THK, HIWIN standards, 15mm-45mm width

- Linear Bearings: Ball bushings, plain bearings, self-aligning

- Roller Bearings: Deep groove, angular contact, thrust bearings

- Slewing Rings: For rotational applications up to 360°

Fasteners & Connectors

- Precision Bolts: Socket head, hex head, Torx drive

- Locknuts: Nylon insert, prevailing torque, all-metal

- Dowel Pins: Straight, tapered, spring-loaded

- Couplings: Flexible, rigid, beam, jaw types

Transmission Components

- Gears: Spur, helical, bevel, worm gears

- Ball Screws: Precision ground, rolled, miniature

- Timing Belts: Rubber, polyurethane, steel cord

- Chain Drives: Roller chain, silent chain, leaf chain

Sensors & Actuators

- Proximity Sensors: Inductive, capacitive, photoelectric

- Position Sensors: Linear potentiometers, encoders

- Linear Actuators: Ball screw, belt drive, pneumatic

- Motor Controllers: Stepper, servo, brushless DC

Cables & Hose Carriers

- Cable Carriers: Plastic, steel, hybrid types

- Flexible Cables: High-flex, shielded, specialty

- Pneumatic Hoses: Nylon, PU, Teflon materials

- Robot Dresspacks: Complete cable management systems

Tools & Fixtures

- Tool Holders: Collet chucks, hydraulic, shrink fit

- Workholding Fixtures: Vises, chucks, custom fixtures

- Alignment Tools: Dial indicators, laser alignment

- Measurement Tools: Calipers, micrometers, CMM probes

Accessory Selection Tips from Our Engineers

“When selecting accessories, always consider the entire system, not just individual components. For example, choosing the right coupling can reduce vibration transmission by 70% and extend bearing life significantly. We recommend specifying accessories from the same supplier to ensure compatibility and reduce sourcing complexity.”

Complete Custom Manufacturing Process: From Design to Installation

Let me walk you through our process. We’ve refined this over 18 years, and it works every time. No shortcuts, no surprises, just consistent quality.

-

1

Requirement Analysis

We start by understanding your exact needs – load requirements, precision specs, environment, lifespan expectations. This is the most important step!

-

2

Design & Simulation

Our engineers use AI-assisted design and FEA simulation to optimize the component before we even touch metal. This catches potential issues early.

-

3

Material Selection & Procurement

We source only certified materials with full traceability. No mystery metals here – you get exactly what you pay for.

-

4

Precision Machining Processes

We use multiple advanced machining techniques to create your parts with extreme precision:

- 5-Axis CNC Machining: Simultaneous movement along X, Y, Z axes plus A and B rotational axes, allowing machining at any angle without re-fixturing. Tolerances as tight as ±0.002mm.

- Milling: Uses rotating cutters to remove material. Roughing with adaptive paths (30-40% tool engagement), finishing with light passes and climb milling for clean edges.

- Turning: Parts rotate on a lathe while stationary tools remove material. Perfect for symmetrical cylindrical parts like shafts and hubs.

- Drilling & Tapping: Creates precise holes and threads. Automatic drill bit change for different diameters, tapping for internal threads.

- Grinding: For final surface finishing, achieving Ra 0.2μm surface roughness.

-

5

Heat Treatment & Coating

Surface hardening, corrosion protection, special coatings – we add the finishing touches that make your parts last longer.

- Carburizing: Surface hardness up to 60 HRC for wear resistance

- Nitriding: Improves fatigue resistance and corrosion protection

- Hard Chrome Plating: 5x longer wear life

- Ceramic Coatings: 10x better than paint for corrosion protection

-

6

Testing & Installation

We test every component to ensure it meets or exceeds your specs, then send our technicians to help with installation and commissioning.

Our Secret Sauce: AI-Enhanced Machining

“Our AI system analyzes real-time sensor data during machining to adjust feeds and speeds automatically. This reduces tool wear by 40% and improves surface finish consistency by 65%. We’ve even achieved 99.9% accuracy on critical dimensions with this technology.”

Machining Parameters for Common Materials

- Stainless Steel 304: Roughing at 0.08-inch DOC, 0.008-inch/rev feed rate, 1500 RPM spindle speed

- Aluminum 6061-T6: Roughing at 0.12-inch DOC, 0.015-inch/rev feed rate, 3000 RPM spindle speed

- Titanium Alloy: Roughing at 0.04-inch DOC, 0.004-inch/rev feed rate, 800 RPM spindle speed

- Alloy Steel 4140: Roughing at 0.10-inch DOC, 0.010-inch/rev feed rate, 2000 RPM spindle speed

Key Optimization Techniques: Balance Performance & Cost

Precision anodized aluminum components with special surface treatments – demonstrating wear resistance enhancement and vibration dampening optimization techniques

Here’s where we really earn our money. Anyone can make a precision part, but making one that performs great and lasts long without breaking the bank? That’s an art form.

High Precision Control

We use advanced probing systems and in-process measurement to ensure every part meets your exact specifications.

-

- ±0.005mm tolerance on critical dimensions

- Surface roughness down to Ra 0.2μm

- In-process inspection reduces scrap by 75%

Test Data*: Precision Improvement

“Our AI-optimized machining processes improved dimensional accuracy by 35% compared to traditional methods.”

Wear Resistance Enhancement

Special surface treatments and coatings significantly extend component life in high-wear applications.

-

- Hard chrome plating: 5x longer wear lifeCeramic coatings: 10x better than paintCarburizing: Surface hardness up to 60 HRC

Test Data*: Wear Life Improvement

“Our coated guide rails lasted 2.8x longer than uncoated rails in a high-speed EV assembly line.”

Vibration Dampening

We design components with optimized geometry and materials to reduce vibration and noise.

-

- Finite element analysis for vibration optimization

- Special alloys reduce resonance by 65%

- Damping coatings reduce noise by 40%

Test Data*: Vibration Reduction

“Our anti-vibration brackets reduced system vibration from 12G to 4G in a high-speed robotic application.”

Cost Control Strategies

We help you get the performance you need without overspending through smart design and material choices.

-

- Design for manufacturability reduces costs by 25%

- Material optimization matches performance to budget

- Life cycle costing analysis shows true ROI

Test Data*: Cost Savings

“Our optimized designs reduced client’s total cost of ownership by 32% over 5 years.”

2025-2026 Application Cases: Real Results from Real Projects

Modern industrial robotics assembly line with automated solar panel manufacturing – showcasing real-world application of custom automation precision parts

Industrial Robotics: 6-Axis Arm Upgrade

We upgraded all the precision components for a major robotics manufacturer’s 6-axis arms.

Results:

- Positioning accuracy improved by 42%

- Cycle time reduced by 18%

- Maintenance costs cut by 55%

- Component life extended to 8 years

- Client ROI: 12 months

EV Assembly Line: High-Speed Conveyor System

We designed custom guide rails and brackets for a new EV battery assembly line.

Results:

- Line speed increased by 25%

- Downtime reduced to 0.5% from 4%

- Maintenance interval extended to 8000 hours

- Zero failures in 18 months of operation

- Annual savings: $1.2 million

Food Processing: Hygienic Automation System

We created custom stainless steel components for a food packaging line requiring strict hygiene standards.

Results:

- Measures all FDA and EU hygiene standards

- Cleaning time reduced by 60%

- Corrosion rate reduced to near zero

- Component life extended to 12 years

- Improved product safety compliance

AGV System: Autonomous Transport Vehicles

We designed custom drive components and navigation brackets for a fleet of AGVs.

Results:

- Navigation accuracy improved to ±2mm

- Battery life extended by 30%

- Maintenance requirements cut by 70%

- Vehicle availability increased to 98.5%

- Operational efficiency up 40%

2026 Trends & Risk Warning: What You Need to Watch

Engineer monitoring smart factory operations with tablet and real-time IoT sensors – illustrating Industry 4.0 trends including AI optimization and 5G integration

Hot Trends for 2026

- AI Design Optimization: Automated design reduces development time by 50%

- Sustainable Materials: Recycled alloys and green manufacturing

- Smart Monitoring: IoT sensors for predictive maintenance

- EV Compatibility: Parts designed specifically for electric vehicle production

- 5G Integration: Wireless connectivity for real-time data sharing

Risk Warning: Common Pitfalls

- Precision Errors: Using standard parts in high-precision applications

- Material Fatigue: Not accounting for cyclic loading

- Corrosion Issues: Ignoring environmental factors

- Regulatory Non-Compliance: Not meeting industry standards

- Supply Chain Risks: Over-reliance on single material sources

Our 2026 Prediction

“By 2027, 80% of new automation systems will use AI-optimized components with built-in health monitoring. This will reduce operational costs by 40% and increase equipment availability to 99%.”

Frequently Asked Questions

Q: How much does a custom automation part cost?

A: It depends on complexity and materials, but expect to pay 30-60% more than off-the-shelf parts. However, the long-term savings usually pay for this in 12-18 months.

Q: What tolerances can you achieve?

A: We regularly hold tolerances as tight as ±0.002mm on critical dimensions. The actual tolerance depends on the material, part size, and complexity.

Q: What standards do you follow?

A: We follow ISO 9001, ISO 13485 for medical applications, IATF 16949 for automotive, and various industry-specific standards depending on the application.

Q: How long does it take to make a custom part?

A: Simple parts can be done in 2-4 weeks, complex components take 6-12 weeks. We can sometimes expedite for an additional fee.

Q: Do you offer reverse engineering services?

A: Absolutely! We have 3D scanning equipment and can create improved versions of existing parts with better performance and longer life.

Q: What’s the warranty on custom components?

A: We offer standard 1-year warranties, but can provide extended warranties up to 5 years for critical applications with proper maintenance agreements.

Ready to Start Your Custom Automation Project?

Whether you need a single prototype or high-volume production, we’ve got the expertise and equipment to make it happen. Let’s bring your design to life!