Introduction

CNC (Computer Numerical Control) metal engraving technology represents the pinnacle of modern manufacturing precision. This advanced process combines computer control systems with mechanical engineering to achieve unparalleled accuracy in metalworking. As industries demand increasingly complex and precise components, CNC metal engraving has emerged as a cornerstone technology in aerospace, automotive, electronics, medical device manufacturing, and beyond.

This comprehensive guide explores the fundamental principles, technical features, practical applications, and future trends of CNC metal engraving technology. Whether you’re a manufacturing professional, engineering student, or technology enthusiast, this article provides valuable insights into this transformative manufacturing process.

1. CNC Metal Engraving Overview

Definition and Core Concepts

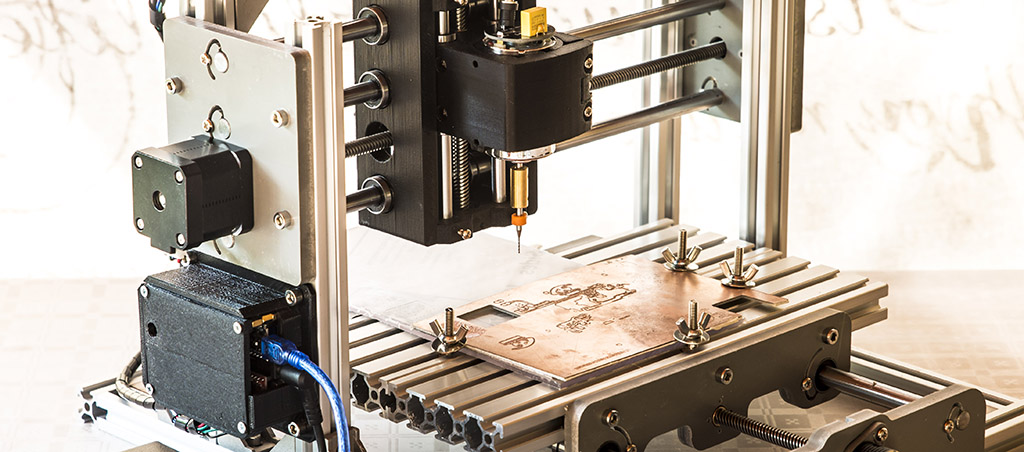

CNC metal engraving is a precision machining process that utilizes computer numerical control technology to automate cutting tools for engraving, milling, and shaping operations on metal surfaces. Unlike traditional manual or mechanical engraving methods, CNC technology enables highly accurate, repeatable, and efficient metalworking.

Key Technical Advantages

High Precision Control

CNC metal engraving achieves micron-level precision with tolerances typically less than 0.01mm. This level of accuracy is essential for manufacturing components that require exacting specifications and tight tolerances.

Automated Operation

The automated nature of CNC systems eliminates the need for constant human intervention. Once programmed, the machine can operate continuously without manual adjustment, significantly reducing labor costs and human error.

Strong Repeatability

One of the most significant advantages of CNC technology is its exceptional repeatability. The same program can produce identical results across multiple workpieces, ensuring consistency in mass production.

High Efficiency Production

CNC machines can operate 24 hours a day with minimal supervision, increasing production efficiency by 5-10 times compared to traditional methods. This continuous operation capability dramatically reduces manufacturing lead times.

Complex Shape Processing

CNC metal engraving excels at creating intricate 3D surfaces and complex contours that would be impossible or impractical to achieve with conventional methods. The multi-axis control systems enable machining of geometrically sophisticated components.

2. Process Principles and Technical Features

Working Principles of CNC Engraving

Digital Command Input

The foundation of CNC technology lies in its ability to interpret and execute G-code instructions. G-code is an international standard programming language that defines tool paths, speeds, feed rates, and other critical machining parameters.

Multi-axis Coordinated Control

Modern CNC engraving machines typically feature X, Y, and Z linear axes, with advanced systems incorporating rotational and tilting axes. This multi-axis coordination enables the creation of complex 3D geometries with exceptional precision.

Tool Path Planning

Sophisticated algorithms optimize cutting paths to minimize travel time, reduce tool wear, and enhance surface finish quality. These intelligent path planning systems significantly improve overall machining efficiency.

High Precision Control Features

Micron-level Accuracy

CNC metal engraving systems achieve core positioning accuracy ranging from 0.002mm to 0.01mm, enabling the production of components with extremely tight tolerances.

Closed-loop Feedback Systems

Advanced CNC machines incorporate real-time monitoring and dynamic error compensation systems. These closed-loop systems continuously adjust for mechanical imperfections and thermal expansion, ensuring consistent accuracy throughout the machining process.

High-speed Spindles

Modern CNC engraving machines feature high-speed spindles capable of reaching up to 20,000 RPM, enabling faster material removal rates while maintaining surface finish quality.

CAD/CAM Technology Applications

3D Model Design

Computer-Aided Design (CAD) software creates precise digital 3D models that serve as the foundation for the machining process. Popular CAD platforms include SolidWorks, AutoCAD, Fusion 360, and CATIA.

Tool Path Generation

Computer-Aided Manufacturing (CAM) software automatically calculates and generates optimized tool paths based on the CAD model. This software considers material properties, tool characteristics, and machine capabilities to develop efficient machining strategies.

Simulation Verification

Virtual machining simulations allow operators to preview the entire manufacturing process before physical production begins. This capability helps identify potential issues and optimize processes before committing to actual production.

3. Material Selection and Applications

Aluminum Alloys

Material Properties

Applications

Aluminum alloys are widely used in electronics, aerospace, and automotive industries due to their lightweight properties and excellent machinability. Their high strength-to-weight ratio makes them ideal for components requiring both structural integrity and reduced weight.

Surface Treatment Options

Aluminum’s versatility allows for various surface treatments including anodizing, powder coating, and polishing, making it suitable for both functional and decorative applications.

Copper Alloys

Material Properties

Applications

Copper alloys are preferred for electrical components and decorative items due to their superior electrical conductivity and attractive surface finish. They are commonly used in heat exchangers, electrical contacts, and architectural elements.

Steel

Material Properties

Applications

Steel is valued for its high strength and durability, making it suitable for structural components, tooling, and machinery parts. However, its higher hardness requires more robust cutting tools and specialized machining parameters.

Titanium Alloys

Material Properties

- Temperature Resistance: Extremely high

Applications

Titanium alloys excel in aerospace and medical applications where high strength, lightweight properties, and corrosion resistance are critical. Their biocompatibility makes them ideal for surgical implants and medical devices.

Material Selection Guidelines

Mass Production

For high-volume manufacturing, aluminum alloys are typically preferred due to their excellent machinability and lower material costs.

High Precision Requirements

Titanium alloys and stainless steels are recommended for applications requiring exceptional dimensional stability and precision.

Decorative Applications

Copper alloys and aluminum are ideal for decorative purposes due to their aesthetic appeal and versatile surface treatment options.

Special Environment Applications

Stainless steels and titanium alloys are suitable for harsh environments due to their superior corrosion resistance.

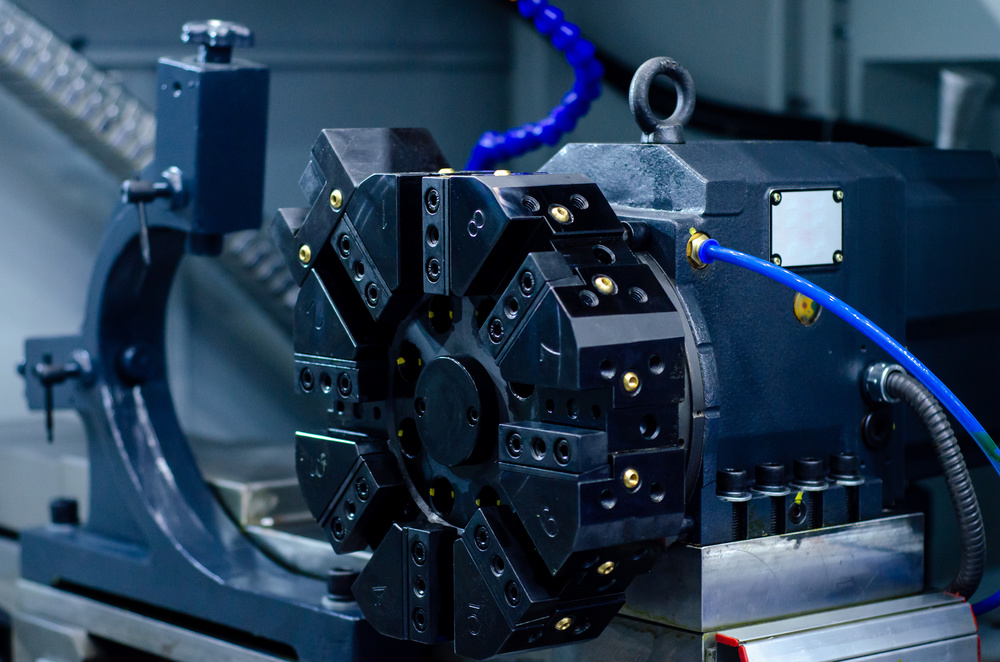

4. Tool Selection and Management

Tool Type Selection

Flat-end Mills

Flat-end mills are the most versatile tool type, suitable for face milling, slotting, and profile machining. Their flat cutting surface makes them ideal for creating flat surfaces and sharp corners.

Ball-end Mills

Ball-end mills feature a spherical cutting surface that excels at 3D contouring and surface finishing. They produce smooth surface transitions and are essential for complex curved geometries.

V-shaped Cutters

V-shaped cutters utilize conical cutting edges for detailed engraving and texturing applications. They are particularly effective for creating decorative patterns and precise lettering.

Tool Material Characteristics

High-Speed Steel (HSS)

HSS tools are suitable for general-purpose machining of softer materials and offer good toughness for interrupted cuts.

Carbide

- Wear Resistance: Excellent

Carbide tools provide superior performance for machining harder materials and offer significantly longer tool life compared to HSS.

Super-hard Materials

- Tool Life: Exceptionally long

Super-hard materials including ceramics and diamond-coated tools are used for specialized applications requiring maximum tool life and performance.

Tool Life Management

Wear Monitoring

Key indicators of tool wear include:

- Deteriorating surface quality

Maintenance and Care

- Proper tool holder lubrication

- Timely replacement of worn components

Life Prediction

Tool life can be predicted based on:

- Historical performance data

Selection Considerations

Material Characteristics

Tool selection must consider the hardness, toughness, and thermal properties of the workpiece material.

Machining Requirements

Precision requirements, surface finish specifications, and production efficiency goals influence tool selection.

Cost-effectiveness

Balancing tool costs with machining efficiency is essential for optimizing production economics.

Equipment Compatibility

Ensuring compatibility between tools and machine tool holder systems is critical for achieving accurate results.

5. Processing Flow and Steps

Preparation Stage

CAD Design

The first step involves creating a precise 3D model using CAD software. This digital representation defines the component’s geometry, dimensions, and tolerances.

CAM Programming

CAM software generates optimized tool paths based on the CAD model. This stage involves selecting appropriate cutting tools, defining machining strategies, and setting cutting parameters.

Material Preparation

Workpiece materials are selected, cut to size, and prepared for machining. Proper material handling and storage are essential to maintain material properties and prevent contamination.

Tooling and Fixturing

Specialized fixtures are designed and prepared to securely hold the workpiece during machining. Proper fixturing ensures stability and accuracy throughout the process.

Machining Stage

Roughing

The roughing operation quickly removes excess material to establish the basic component shape. This stage prioritizes material removal rate over surface finish quality.

Semi-finishing

Semi-finishing operations refine the component geometry and prepare surfaces for the final finishing pass. This stage balances material removal rate with surface quality.

Finishing

The finishing operation achieves the final dimensional accuracy and surface finish requirements. This stage uses 精细 cutting parameters to produce the highest quality results.

In-process Inspection

Real-time quality monitoring systems continuously check dimensions and surface quality during machining, allowing for immediate adjustments if deviations are detected.

Post-processing Stage

Deburring

Removing burrs and sharp edges from machined components improves safety, functionality, and aesthetic appearance.

Cleaning

Thorough cleaning removes cutting fluids, chips, and contaminants from the finished components.

Quality Inspection

Comprehensive inspection verifies dimensional accuracy, surface finish, and overall quality against specifications.

Surface Treatment

Final surface treatments such as polishing, coating, or heat treatment enhance component performance and appearance.

Quality Control Key Points

Precision Control

Maintaining micron-level accuracy throughout the manufacturing process.

Quality Assurance

Implementing comprehensive monitoring systems to ensure consistent quality.

Efficiency Optimization

Continuously refining parameters to maximize production efficiency.

Safety Protection

Adhering to strict operational procedures to ensure workplace safety.

6. Design and Programming

CAD Design Software Selection

SolidWorks

SolidWorks is a powerful mechanical design software offering advanced features for complex part design and assembly modeling. Its intuitive interface and extensive toolset make it a popular choice for mechanical engineers.

AutoCAD

AutoCAD is the industry standard for 2D drafting and design. Its precision and versatility have made it a staple in engineering and architecture for decades.

Fusion 360

Fusion 360 is a cloud-based platform that integrates CAD, CAM, and CAE capabilities. Its collaborative features and accessibility make it ideal for modern design teams.

CATIA

CATIA is a high-end design software primarily used in aerospace and automotive industries for complex surface modeling and system integration.

Design Considerations

Precision Requirements

- Accurate tolerance specifications

- Appropriate clearance allowances

- Ensuring manufacturability

Structural Optimization

- Avoiding excessively thin walls

- Implementing proper ribbing and support structures

- Enhancing structural integrity

Manufacturability

- Considering machining feasibility

- Avoiding overly complex geometries

- Minimizing machining difficulty

Material Properties

- Selecting appropriate design parameters based on material characteristics

- Accounting for thermal expansion and other material behaviors

CAM Programming Essentials

Tool Path Planning

Optimizing tool paths to minimize travel time and improve machining efficiency.

Layered Machining

Implementing roughing, semi-finishing, and finishing strategies to balance efficiency and quality.

Cutting Parameters

Setting appropriate spindle speeds, feed rates, and depth of cut based on material and tool characteristics.

Safety Heights

Establishing proper clearance distances to prevent tool collisions with the workpiece or fixtures.

Technical Workflow

The standard workflow for CNC machining follows:

- CAD Design → 2. CAM Programming → 3. Machine Machining

This integrated approach ensures seamless transition from design concept to physical component.

7. Common Problems and Solutions

Over-travel Alarms

Symptoms

Sudden machine stoppage with over-travel error messages displayed on the control panel.

Possible Causes

- Program errors: Machining paths exceeding machine travel limits

- Limit switch malfunctions: Hardware failures causing false alarms

- Coordinate system setup errors: Incorrect workpiece coordinate origin

Solutions

- Program path verification: Confirm that machining paths stay within machine travel limits

- Limit switch testing: Verify the functionality of all limit switches

- Coordinate system re-establishment: Correctly set workpiece coordinate origins

- Soft limit adjustments: Modify soft limit parameters based on actual requirements

Tool Wear and Breakage

Symptoms

Deteriorating surface quality, increased dimensional inaccuracies, and unusual machining sounds.

Possible Causes

- Inappropriate cutting parameters: Incorrect spindle speeds, feed rates, or depth of cut

- Inadequate cooling: Insufficient coolant flow or improper coolant selection

- Excessive material hardness: Workpiece material hardness exceeding tool capabilities

Solutions

- Cutting parameter optimization: Set appropriate spindle speeds, feed rates, and depth of cut

- Coolant system verification: Ensure proper coolant flow and selection

- Tool selection: Choose appropriate tool materials and coatings based on workpiece material

- Regular inspections: Periodically check tool wear and replace worn tools promptly

Machining Accuracy Issues

Symptoms

Dimensional deviations, poor surface finish, and geometric distortion.

Possible Causes

- Machine accuracy degradation: Reduced geometric accuracy due to prolonged use

- Tool runout: Excessive tool holder runout affecting cutting performance

- Material deformation: Thermal distortion or stress relief during machining

Solutions

- Machine accuracy verification: Check machine geometric accuracy and repeatability

- Tool installation: Ensure proper tool installation and minimal runout

- Material deformation considerations: Implement strategies to minimize material distortion

- Machining strategy optimization: Adopt appropriate machining strategies and parameters

Preventive Measures

Daily Maintenance

- Regular cleaning and calibration

- Lubrication system checks

- Component inspection and replacement

Operational Procedures

- Strict adherence to operating protocols

- Comprehensive training programs

- Documentation and record-keeping

Quality Monitoring

- Implementing inspection systems

- Statistical process control

- Continuous improvement initiatives

8. Technical Differences and Comparisons

Rotary Engraving

Technical Characteristics

- Rotary cutting tools: High-speed cutting (8,000-24,000 RPM)

- Material compatibility: Suitable for various metal materials

Core Advantages

- Low cost: High equipment penetration rate

- Deep engraving: Long-lasting machining results

Main Disadvantages

- Rapid wear: Frequent tool replacement required

- Slower speed: Relatively lower machining efficiency

Laser Engraving

Technical Characteristics

- Non-contact processing: Laser beam thermal sublimation

- High precision: Micron-level machining capability

- Fast speed: No tool change required

Core Advantages

- High efficiency: Optimal speed and precision balance

- Environmentally friendly: No tool maintenance requirements

Main Disadvantages

- High cost: Significant equipment investment

- Shallow engraving: Material selectivity limitations

Diamond Drag Engraving

Technical Characteristics

- Drag scraping: Diamond-tipped tools

- Ultra-high hardness: Non-rotational machining

- High precision: Excellent control accuracy

Core Advantages

- Long tool life: Low operating costs

- High quality: Suitable for hard metals

Main Disadvantages

- Shallow engraving: Slower machining speed

- Limited applications: Highly specialized equipment

Technical Comparison Summary

|

Comparison Dimension

|

Rotary Engraving

|

Laser Engraving

|

Diamond Engraving

|

|

Efficiency Comparison

|

Medium efficiency

|

Most efficient

|

Lower efficiency

|

|

Cost Comparison

|

Low investment cost

|

High investment cost

|

Low maintenance cost

|

|

Precision Comparison

|

Medium precision

|

Highest precision

|

High precision

|

|

Selection Recommendation

|

Economical and practical

|

High efficiency and precision

|

Fine hard metal applications

|

9. Application Fields and Cases

Aerospace Industry

Application Cases

- Titanium alloy aerospace components: Aircraft structural parts, engine blades

- Engine components: Combustion chambers, turbine blades

- Satellite precision structures: Antenna mounts, optical systems

Technical Requirements

- High-temperature materials: Titanium alloys, high-temperature alloys

- Complex surfaces: 3D contoured structure machining

- Lightweight design: Thin-walled structure machining

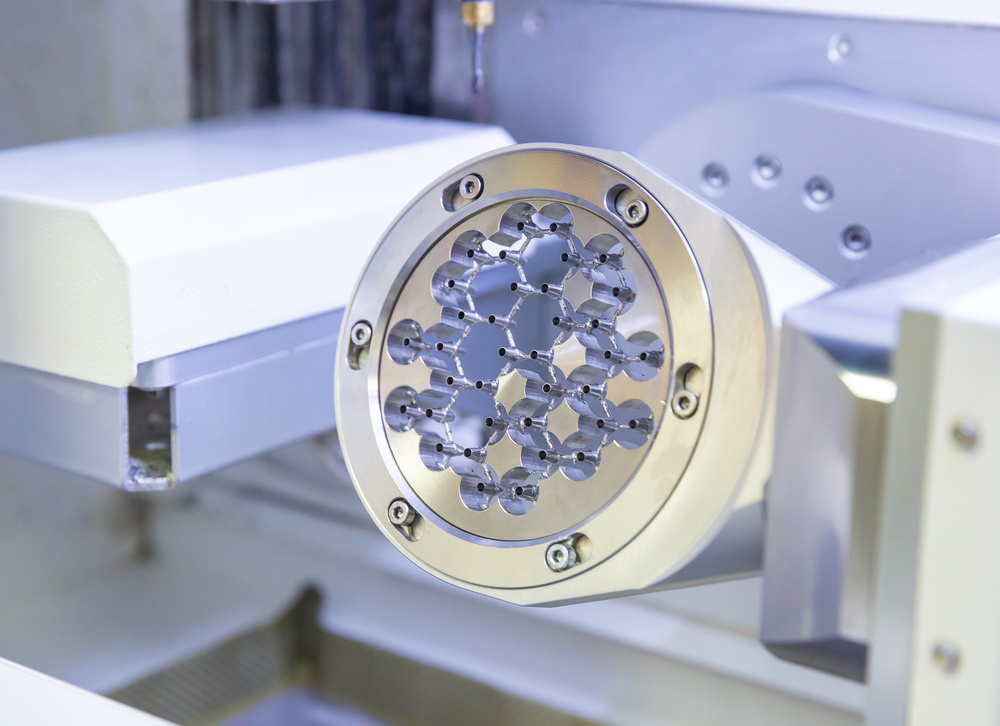

Electronics Manufacturing

Application Cases

- Mobile phone frame textures: Decorative texture engraving

- Camera modules: Microstructure machining

- Precision circuit boards: Conductive trace engraving

Technical Requirements

- Precision requirements: ±0.005 mm

- Materials: Aluminum alloys, stainless steels

- Surface finish: Ra 0.4 μm

Medical Equipment

Application Cases

- Orthopedic implants: Artificial joints, spinal implants

- Surgical instruments: Micro-surgical tools

- Dental restorations: Dental implants, crowns

Technical Requirements

- Biocompatibility: Medical standard compliance

- Sterile processing: Clean environment requirements

- Ultra-high precision: Micron-level control

Other Application Fields

Mold Industry

Automotive Industry

Jewelry Manufacturing

10. Development Trends and Outlook

High-Speed Precision Trends

CNC metal engraving technology is advancing toward higher speeds and greater precision, continuously pushing technological boundaries.

Spindle Speed

Breakthroughs exceeding 100,000 RPM significantly enhance machining efficiency and surface quality.

Positioning Accuracy

Achieving nanometer-level precision capabilities to meet ultra-precision machining requirements.

Machining Speed

3-5 times faster processing speeds shorten production cycles and increase throughput.

Surface Quality

Achieving mirror-like surface finishes reduces post-processing requirements.

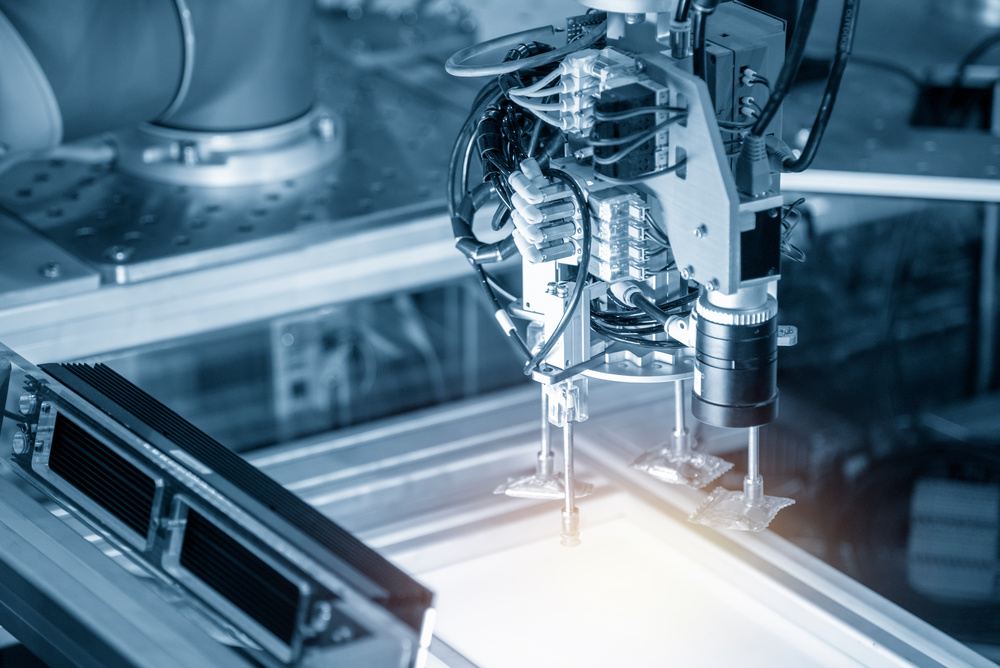

Intelligent Automation Upgrades

The integration of artificial intelligence, IoT, and other new technologies is driving CNC machining toward intelligent, automated development.

AI Intelligent Optimization

Automatic optimization of process parameters enhances machining quality and efficiency.

Automatic Tool Changing

Automatic tool replacement and detection systems reduce manual intervention.

Robotic Loading/Unloading

Implementing fully automated production workflows with robotic systems.

Cloud Monitoring

Remote data monitoring and analysis enable predictive maintenance capabilities.

New Material and Process Applications

The continuous emergence of new materials and development of new processes are driving continuous innovation in CNC machining technology.

Composite Materials

Precision machining of carbon fiber, ceramic matrix composites, and other advanced materials.

Ceramic-Metal Composites

Processing technologies for ceramic-metal composite structures.

Additive-Subtractive Hybrid Manufacturing

Combining 3D printing with CNC machining for hybrid manufacturing solutions.

Green Processes

Environmentally friendly machining processes reduce environmental impact.

Technology Integration Innovation

Digital Twin

Virtual and physical reality integration for digital factory implementations.

5G + Industrial Internet

Device connectivity and interoperability for smart manufacturing.

Edge Computing

Real-time control capabilities improve response times and system performance.

Blockchain

Quality traceability systems ensure product quality and authenticity.

Application Field Expansion

Biomedical Applications

Personalized customization of medical products and devices.

Micro-Nano Manufacturing

Technological breakthroughs in micro-nano scale structure machining.

Space Manufacturing

Development of manufacturing technologies for space environments.

Quantum Devices

Machining requirements for quantum technology-related components.

Sustainable Development

Energy Conservation and Emission Reduction Technologies

Reducing energy consumption and environmental pollution.

Circular Economy Models

Resource recycling and utilization to improve resource efficiency.

Green Manufacturing Processes

Environmentally friendly machining technologies for sustainable development.

Smart Manufacturing Ecosystems

Building comprehensive smart manufacturing industrial chains.

Future Development Timeline

- 2025: AI full automation, nanometer-level precision

- 2030: Digital twin, multi-technology integration

- 2035: Autonomous intelligence, space manufacturing

- 2040+: Quantum manufacturing, unlimited possibilities

11. Conclusion

Core Advantage Summary

CNC metal engraving technology offers high-precision machining, high-efficiency production, multi-functional applications, and sustainable development capabilities. These advantages have established it as a cornerstone technology in modern manufacturing, representing the future direction of advanced manufacturing.

Key Technical Points

Process Technology

- Multi-axis coordinated control technology

- High-speed spindle technology

- Precision tool technology

Material Selection

- Aluminum alloys: Lightweight, easy to machine

- Stainless steels: High strength, corrosion resistant

- Titanium alloys: High temperature resistant, high strength

- Copper alloys: Good conductivity, decorative

Quality Control

- In-process inspection and compensation

- Surface quality monitoring

- Dimensional accuracy assurance

- Process parameter optimization

Future Development Recommendations

Technology Upgrades

- Implementing AI intelligent optimization systems

- Upgrading high-speed spindle technology

- Developing automated loading/unloading systems

- Establishing digital factories

Talent Development

- Strengthening skill training systems

- Developing Versatile talents

- Establishing technical certification systems

- Promoting industry-academia-research cooperation models

Market Expansion

- Developing emerging application fields

- Providing customized solutions

- Establishing service network systems

- Promoting international development

Final Outlook

CNC metal engraving technology is advancing toward high-speed precision, intelligence, and green development. It will play a crucial role in manufacturing transformation and upgrading, contributing core technical capabilities to the smart manufacturing era.

As industries continue to demand higher precision, greater efficiency, and more sustainable manufacturing solutions, CNC metal engraving technology will remain at the forefront of innovation, driving progress across multiple sectors and shaping the future of manufacturing worldwide.

This comprehensive guide provides a detailed overview of CNC metal engraving technology, from fundamental principles to advanced applications. As technology continues to evolve, staying informed about these developments will be essential for professionals in the manufacturing industry.