Simply put, a CNC prototype is an “early product sample” made using Computer Numerical Control (CNC) machining technology—it is not a final mass-produced product, but a “design stand-in” used for “error testing, verification, and optimization” during the product development phase.

For example, before mass production, mobile phone manufacturers use CNC milling to create aluminum alloy housing prototypes to test grip comfort; medical device companies machine titanium alloy part prototypes to verify precise compatibility with other components. Compared to ordinary “handmade samples,” CNC prototypes have clear core advantages:

- High precision: Dimensional error can be controlled within ±0.01mm, almost matching the precision of mass-produced parts;

- Authentic materials: It uses the same metals (aluminum, titanium alloy) or plastics (ABS, PC) as the final product, truly reflecting physical properties;

- High reproducibility: Complex structures (such as curved surfaces, microholes, and threads) can be fully machined, even simulating the surface texture of mass-produced products.

Here’s a vivid example: When developing a smartwatch, a 3D-printed plastic case only shows the appearance, but a CNC prototype made of aluminum alloy can not only fit the motherboard and battery (to verify assemblability) but also test wear resistance and impact resistance (to verify functionality)—this is the core value of a CNC prototype: turn “on-paper designs” into tangible objects that you can touch, use, and test.

Many people ask: “Isn’t it faster to skip prototyping and go straight to production?” However, almost no enterprise in the industry does this, because CNC prototypes help you avoid 3 “fatal pitfalls”:

-

Identify design flaws in advance to avoid mass production scrap

A home appliance company once designed a stainless steel water kettle—on paper, it looked fine, but when the CNC prototype was made, two problems emerged: the spout angle was too steep (causing water to leak when pouring) and the lid clasp was too loose (failing to seal properly). If they had gone straight to mold production, tens of thousands of products would have become scrap, costing at least hundreds of thousands of yuan. The CNC prototype, by contrast, only cost a few hundred yuan and revealed the issues in 3 days.

-

Test physical performance to ensure product usability

Not all designs work “as intended once made”: For example, the carbon fiber frame of a drone had sufficient calculated strength, but after the CNC prototype was machined, a tensile test showed that the joint was prone to breaking. Adjusting the structure (e.g., adding reinforcing ribs) at this stage is far cheaper than recalling mass-produced products. For titanium alloy parts of medical devices, CNC prototypes also allow early biocompatibility testing to avoid problems after implantation in the human body.

-

Reduce development costs and speed up product launch

A mass-production mold costs at least tens of thousands of yuan (and often hundreds of thousands), and mold modification costs are extremely high. CNC prototypes enable “rapid iteration”: When designing a headphone case, the first prototype was too thick (poor grip), but a thinner version was remade in 3 days after design adjustments. After 3-4 rounds of tweaks, the final mold was made—this saves over 60% of the cost compared to modifying the mold after production.

Don’t think CNC prototyping is “too advanced”—its process is actually clear, with the core difference from mass production being “small batches and fast pace”:

-

Step 1: Import design files

First, a 3D model (in formats like STEP or IGS) is needed. Engineers import the model into CNC programming software, mark areas to be milled or drilled, and set machining paths (e.g., mill the outer shape first, then drill microholes)—this step is like “drawing a route map” for the machine.

-

Step 2: Select materials and clamp the workpiece

Materials are chosen based on needs: Aluminum alloy (6061-T6) or titanium alloy for strength testing; ABS or PC for appearance simulation; carbon fiber for lightweight requirements. The material is then clamped to the CNC machine’s worktable to prevent shaking during machining.

-

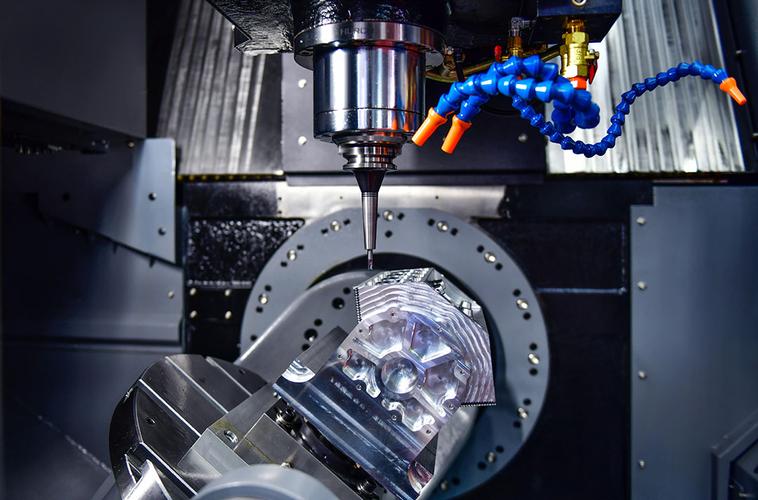

Step 3: CNC machining—”carve” the prototype

Following the programmed path, the machine uses tools like milling cutters and drill bits to “gradually remove excess material”: For a mobile phone middle frame prototype, the machine first mills the rough shape, then refines details (e.g., button holes, camera holes) with precision up to ±0.005mm—about 1/10 the diameter of a human hair.

-

Step 4: Post-processing + quality inspection

Machined prototypes may have burrs that need sanding and polishing; to simulate mass-produced appearance, additional processes like anodizing (for metals) or painting (for plastics) are used. Finally, calipers and coordinate measuring machines (CMMs) check dimensions to ensure consistency with the design—only qualified prototypes are used for testing.

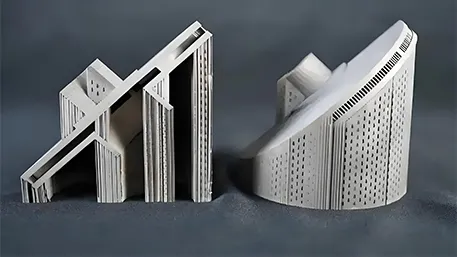

Many people confuse CNC prototypes with 3D-printed prototypes, but they each have strengths—choosing the right one saves time:

In short: If your product is made of metal and needs usability testing (e.g., drone frames, medical parts), choose a CNC prototype; if you only need to check appearance (e.g., toy shapes) or verify complex structures (e.g., hollow lampshades), choose a 3D-printed prototype.

-

How much does a CNC prototype cost?

It depends on materials and complexity: A simple aluminum part (e.g., a 5cm×5cm panel) costs 100-300 yuan; a complex titanium alloy medical part prototype may cost 1000-2000 yuan. The key is “small batches”—one piece costs more per unit than 100 pieces, but it’s far cheaper than making a mold.

-

How quickly can I get a CNC prototype?

1-2 days for simple parts (e.g., flat brackets); 3-5 days for medium-complexity parts (with curved surfaces or threads); about 7 days for complex parts (e.g., polyhedral components)—much faster than mold production (usually 15-30 days).

-

What size CNC prototype can be made?

Generally, CNC machines can handle prototypes up to 1m×2m (e.g., housings for large equipment) and as small as a few millimeters (e.g., watch gear prototypes)—the key factor is the machine’s travel range.

-

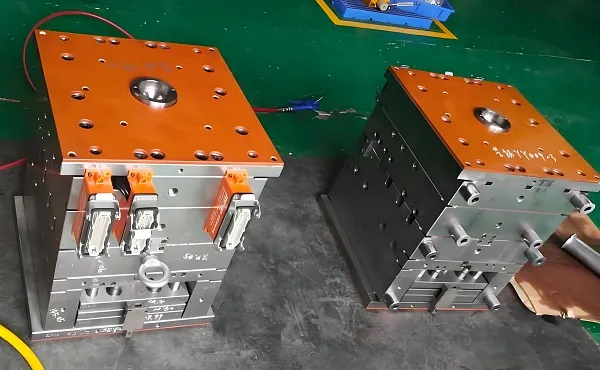

Can CNC prototypes be used for mass production?

Not recommended. CNC prototyping is for “single-piece or small-batch processing” (usually 1-50 pieces). Mass production requires molds, which are more efficient and cost-effective—for example, making 1000 aluminum parts takes 10 days with CNC machining, but only 1 day with a mold.

-

Can individuals make CNC prototypes?

Yes. Many CNC machining manufacturers now offer “small-batch customization”—individuals only need to provide a 3D model and specify materials/requirements to place an order. This is convenient for makers (e.g., making robot parts) and designers (e.g., creating product samples).

Disclaimer

- All information, opinions, and data contained in this article are for the purpose of information transmission only and do not constitute any advice on investment, transactions, law, medical care, or other matters.

- The content of the article is compiled based on public information or created based on the author’s personal understanding. Although every effort is made to ensure accuracy, it does not guarantee the completeness, accuracy, and timeliness of the information, nor does it bear any responsibility for any losses caused by the use of the content of this article.

- If the article involves third-party opinions, pictures, data, and other content, the copyright belongs to the original author. In case of infringement, please contact us for deletion.

- Readers should make independent decisions based on their actual situation and combined with professional opinions. The user shall bear all consequences arising from the use of the content of this article.

Author:

Name: Dr. Benjamin Keller

Nationality: Germany

Titles: Senior Research Scientist, Industrial Technology Consultant

Work Experience and Industry Qualifications:

An expert in the CNC field from Germany, with 25 years of in – depth industry experience. He has long focused on the high – precision optimization of five – axis linkage machining technology, the intelligent upgrade of AI – driven numerical control systems, and the practical application of digital twins in machining scenarios. He is particularly good at solving machining technical problems of complex surfaces in aerospace and precision components in the medical field. He is proficient in advanced programming of G – code and M – code, and is skilled in the debugging and optimization of mainstream numerical control systems such as Fanuc and Siemens. He can build an adaptive model of cutting parameters through machine learning algorithms, use virtual simulation tools to pre – rehearse the machining process and perform error compensation. At the same time, he has the ability to integrate multi – axis machining processes and additive manufacturing technologies, which can effectively improve machining efficiency and precision consistency.