- Electronics: Brass connector pins (tolerance ±0.005 mm) for connectors;

- Plumbing & Sanitary: Custom brass valve cores (surface roughness Ra ≤ 0.4 μm) for faucets;

- Aerospace: Precision brass sensor housings (concentricity ≤ 0.003 mm);

- Watchmaking: Micro brass gear shafts (length-diameter ratio 10:1) for mechanical watches.

1. Technical Essence of Customized Brass CNC Turning

(1) Material Characteristics of Brass and Machining Adaptation

|

Brass Grade

|

Composition (Cu/Zn)

|

Machinability Rating (1=poor, 10=excellent)

|

Key Machining Features

|

|

H62

|

62%/38%

|

8

|

Balanced strength (σb=300 MPa) and ductility; suitable for medium-load parts (e.g., valve stems).

|

|

H65

|

65%/35%

|

9

|

Higher copper content, better surface finish (Ra ≤ 0.4 μm); ideal for precision parts (e.g., watch gears).

|

- Chip Control: Brass produces continuous curly chips during turning; customized chip breaker grooves (e.g., “U-type” for H62) are required to avoid chip entanglement with the tool or workpiece.

- Stickiness Prevention: Brass has moderate adhesion (lower than aluminum but higher than steel); high-speed cutting (V ≥ 200 m/min) or TiN-coated tools reduce built-up edge (BUE) formation.

- Thermal Deformation: Brass has a low thermal expansion coefficient (19×10⁻⁶/°C, 50% lower than aluminum); however, thin-walled parts (thickness ≤ 1 mm) still require cooling to avoid thermal warpage (temperature ≤ 150°C).

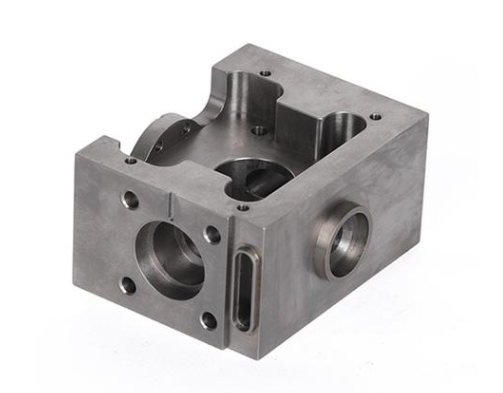

(2) Customization-Driven Geometric Challenges

- Micro-Structure Machining: For micro-parts (e.g., φ0.8 mm electronic pins), tool diameter (≤ 0.5 mm) and spindle runout (≤ 0.001 mm) become critical to avoid tool breakage.

- Multi-Feature Integration: Parts with combined features (e.g., a brass shaft with a φ5 mm eccentric hole + M8×1 thread + 0.5 mm deep annular groove) require precise coordination of tool changes and axis movements.

- Irregular Contours: Non-circular profiles (e.g., hexagonal brass knobs) demand synchronized control of X/Z axes (via NURBS interpolation) to ensure contour accuracy (error ≤ ±0.005 mm).

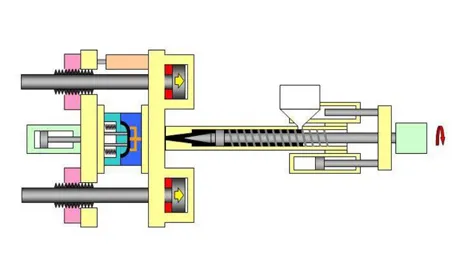

2. Hardware System Architecture for Customized Brass CNC Turning

(1) Key Hardware Modules and Brass-Adapted Specifications

|

Hardware Module

|

Technical Requirements (Brass-Specific)

|

Technical Role

|

|

Cutting Tools

|

– Material: High-Speed Steel (HSS-E, for low-speed fine turning) or TiN-coated Carbide (WC-Co, for high-speed roughing).- Geometry: Front angle γₒ=12°-15° (reduces cutting force), nose radius rₑ=0.1-0.3 mm (for micro-parts).

|

Ensure smooth cutting of brass; minimize BUE and tool wear.

|

|

Spindle Unit

|

– Speed range: 3000-12000 rpm (H65 brass: 8000-12000 rpm for fine turning; H62 brass: 3000-6000 rpm for roughing).- Runout: Radial runout ≤ 0.001 mm (critical for micro-pin machining).

|

Provide stable high-speed rotation; avoid dimensional errors from spindle vibration.

|

|

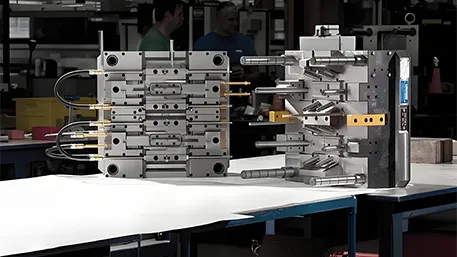

Custom Fixtures

|

– Type: Collet chucks (for cylindrical parts, clamping accuracy ±0.002 mm) or jaw chucks with custom soft jaws (for irregular parts, e.g., hexagonal brass nuts).- Clamping force: 50-500 N (adjustable to prevent deformation of thin-walled brass parts).

|

Secure workpiece positioning; match the unique shape of customized parts.

|

|

Cooling System

|

– Coolant type: Emulsion (concentration 5%-8%, avoids brass oxidation) or synthetic coolant (for high-speed turning, thermal conductivity ≥ 0.5 W/m·K).- Flow rate: 5-15 L/min (directed at cutting zone via 0.5-1 mm diameter nozzles).

|

Reduce cutting temperature; flush chips; prevent brass surface discoloration.

|

|

Tool Turret

|

– Station count: 8-12 stations (accommodates diverse tools: turning tools, threading tools, boring tools for customized features).- Tool change time: ≤ 0.8 s (tool-to-tool, minimizes downtime for multi-feature parts).

|

Support quick tool switching for complex customized geometries.

|

(2) Customization-Enhanced Hardware Upgrades

- Micro-Tool Adaptation: For parts with micro-holes (φ0.3-1 mm), the CNC lathe is equipped with a high-precision micro-boring unit (coaxiality ≤ 0.002 mm) and a tool length sensor (resolution 0.1 μm) to avoid tool overcutting.

- Irregular Workpiece Clamping: For non-circular customized parts (e.g., brass camshafts), a “profile-matching fixture” is used—machined to the exact reverse shape of the workpiece’s base, ensuring clamping contact area ≥ 80% and reducing deformation.

3. Core Control Algorithms for Customized Brass CNC Turning

(1) Complex Path Planning for Custom Geometries

- NURBS Interpolation for Irregular Contours:

- Multi-Feature Process Sequencing:

-

- Rough turning (remove 80% of material, V=250 m/min, f=0.2 mm/r);

-

- Boring (machining the hole, V=200 m/min, f=0.1 mm/r);

-

- Thread turning (M8×1, spindle synchronization accuracy ±0.1°);

-

- Fine turning (final dimension, V=300 m/min, f=0.05 mm/r).

(2) Brass-Specific Error Compensation

- Thermal Deformation Compensation:

-

- Measure cutting zone temperature via a thermocouple (resolution 1°C);

-

- Calculate expansion amount (ΔL = α×L×ΔT, α=19×10⁻⁶/°C);

-

- Adjust the Z-axis position in real time to offset expansion, ensuring length tolerance ≤ ±0.003 mm.

- Tool Wear Compensation:

-

- Measure cutting force via a piezoelectric sensor (resolution 0.1 N);

-

- When force increases by 20% (indicating VB=0.2 mm), automatically adjust the tool radius compensation value (Δr=0.002 mm) to maintain dimensional accuracy.

4. Precision Detection and Calibration Technology

(1) Customized Dimension and Surface Detection

- Dimensional Accuracy Detection:

-

- For micro-parts (e.g., φ1 mm pins): Use a toolmaker’s microscope (magnification 50×, accuracy ±0.0005 mm) to measure diameter and concentricity.

-

- For large parts (e.g., φ100 mm valves): Use a coordinate measuring machine (CMM, accuracy ±0.001 mm) to inspect all customized features (holes, threads, grooves) in one setup.

- Surface Quality Detection:

-

- Surface roughness: Use a contact-type roughness tester (Ra resolution 0.001 μm) to sample 3 points on the workpiece (avoiding edges) — ensure Ra ≤ 0.4 μm for decorative brass parts.

-

- Surface defects: Use a vision inspection system (200× magnification) to detect micro-scratches (depth ≤ 0.001 mm) or oxidation spots (common in brass if coolant is contaminated).

(2) Machine and Tool Calibration

- Spindle Speed Calibration:

- Tool Offset Calibration:

-

- Tool length offset (Z-axis): Ensure thread depth error ≤ 0.01 mm.

-

- Tool radius offset (X-axis): Compensate for tool tip wear (critical for thread profile accuracy).

5. Typical Process Difficulties and Technical Breakthroughs

(1) Micro-Thin-Walled Brass Part Deformation (Thickness ≤ 0.8 mm)

- Flexible Clamping: Use a pneumatic collet chuck with a polyurethane sleeve (Shore hardness 60A) to distribute clamping force—reduce local pressure to ≤ 0.5 MPa, ovality error ≤ 0.005 mm.

- Light-Cutting Strategy: Adopt high speed (V=300 m/min) and low feed rate (f=0.03 mm/r), depth of cut aₚ=0.05 mm (multi-pass: 4-6 passes) to minimize cutting force (< 30 N).

(2) Customized Brass Thread Machining (e.g., M3×0.5 Fine Thread)

- Burr Prevention: Use a “negative rake angle threading tool” (γₒ=-5°) to shear chips instead of tearing brass; after threading, perform a 0.1 mm deep “light cut” on the thread crest to remove burrs.

- Synchronization Optimization: Increase the spindle encoder resolution (from 20 bits to 24 bits) to improve angle control accuracy (±0.05°); use “thread pitch compensation” to correct cumulative pitch error (reduce to ≤ 0.003 mm).

(3) Brass Oxidation and Corrosion (Critical for Plumbing Parts)

- Coolant Management: Use a coolant filtration system (5 μm filter) to remove metal chips; add a corrosion inhibitor (0.5% concentration) to the emulsion to extend anti-oxidation time to 72 hours.

- Post-Machining Treatment: Immediately after turning, clean the workpiece with ethanol (to remove coolant residue) and apply a thin layer of anti-tarnish oil (thickness 5-10 μm) to prevent oxidation.

6. Common Issues and Troubleshooting

(1) Workpiece Surface Scratches

- Curly brass chips scratch the machined surface (common if chip breaker is mismatched).

- Coolant flow is insufficient (nozzle blocked, flow rate < 5 L/min), leading to chip accumulation.

- Replace the chip breaker with a “narrow-groove type” (suitable for brass) to produce short C-shaped chips.

- Clean the coolant nozzle (use a 0.5 mm drill bit to clear blockages) and increase flow rate to 8-10 L/min.

(2) Dimensional Overrun (e.g., Diameter Too Small by 0.008 mm)

- Tool wear exceeds the compensation threshold (VB=0.3 mm, uncompensated).

- Thermal expansion of the workpiece is underestimated (cutting zone temperature reaches 180°C, ΔL=0.006 mm).

- Replace the worn tool and reset the tool radius compensation value (add 0.003 mm to the original offset).

- Increase coolant flow rate to 15 L/min to reduce cutting zone temperature to ≤ 120°C; adjust the thermal compensation coefficient from 19×10⁻⁶/°C to 20×10⁻⁶/°C (for higher accuracy).

Conclusion: The Future of Customized Brass CNC Turned Parts

- Micro-Precision Development: For electronic and watchmaking industries, micro-brass parts with dimensions ≤ 0.5 mm (e.g., φ0.3 mm sensor pins) will require ultra-high-precision CNC lathes (spindle runout ≤ 0.0005 mm) and nanoscale tooling.

- Multi-Material Integration: Customized brass parts will combine with other materials (e.g., brass-aluminum bimetallic shafts) via hybrid CNC processes (turning + laser welding), expanding application scenarios in automotive electronics.

- Green Machining: Dry or minimum quantity lubrication (MQL) systems will replace traditional coolants—MQL uses 5-10 mL/h of vegetable oil (vs. 10 L/min of emulsion), reducing waste and avoiding brass oxidation from coolant contamination.