1. Technical Essence and Geometric Design of Cutting Inserts

(1) Core Geometric Parameters of Inserts

|

Geometric Parameter

|

Definition

|

Impact on Machining Performance

|

|

Nose Radius (rₑ)

|

Radius of the arc connecting the main cutting edge and secondary cutting edge

|

– Small rₑ (0.2-0.4 mm): Suitable for fine turning (Ra ≤ 0.8 μm), reduces cutting forces but increases tool wear.- Large rₑ (1.2-2.0 mm): Suitable for rough turning, improves tool rigidity but may cause vibration in thin-walled parts.

|

|

Lead Angle (κᵣ)

|

Angle between the main cutting edge and the workpiece axis

|

– κᵣ=90°: Suitable for end-face turning, minimizes radial cutting force.- κᵣ=45°-75°: Suitable for external turning, balances radial and axial forces.

|

|

Clearance Angle (αₒ)

|

Angle between the flank face and the workpiece’s machined surface

|

Typically 5°-12°; too small causes flank wear, too large reduces tool rigidity.

|

|

Chip Breaker Groove

|

Special groove on the insert’s rake face

|

Controls chip shape (e.g., C-type, spiral chips) to avoid chip entanglement with the workpiece or tool.

|

(2) Insert Standardization and Interface Matching

- C: Insert shape (diamond, 80° included angle);

- N: Relief angle (0°);

- M: Tolerance class (medium, ±0.05 mm for insert thickness);

- G: Hole type (with through hole for clamping);

- 12: Insert width (12.7 mm);

- 04: Insert thickness (4.76 mm);

- 08: Nose radius (0.8 mm).

- Mechanical clamping: Screw clamping (for through-hole inserts) or lever clamping (for solid inserts) ensures clamping force of 5-8 N·m, controlling insert radial runout ≤ 0.01 mm.

- Tool holder interface: Common standards include CAPTO (for high rigidity, used in heavy-duty turning) and VDI (for quick change, used in automotive mass production), with coaxiality error ≤ 0.005 mm between tool holder and spindle.

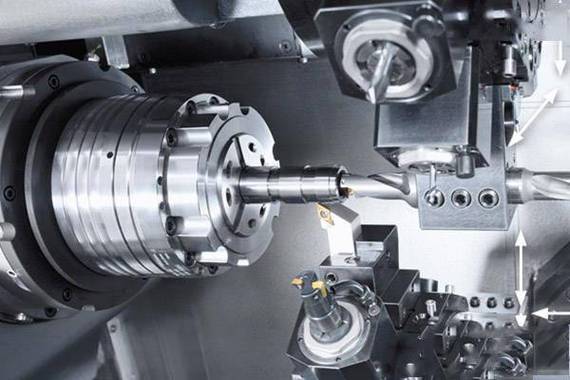

2. Hardware System Architecture for Insert CNC Turning

(1) Key Hardware Modules and Technical Specifications

|

Hardware Module

|

Technical Requirements

|

Technical Role

|

|

Cutting Insert

|

– Material: Carbide (WC-Co, for general steel); Ceramic (Al₂O₃, for high-speed turning of cast iron); CBN (for hardened steel, HRC ≥ 55).- Coating: TiAlN (max service temp 800°C); AlCrN (max service temp 1100°C).

|

Provide cutting edge; coating reduces friction and wear.

|

|

Tool Holder

|

– Rigidity: Bending stiffness ≥ 200 N/μm.- Cooling: Internal coolant channel (flow rate ≥ 15 L/min, pressure ≥ 5 MPa) for chip evacuation.

|

Clamp insert; deliver coolant to cutting zone; absorb cutting vibration.

|

|

Spindle Unit

|

– Speed range: 50-8000 rpm (for carbide inserts); 1000-15000 rpm (for ceramic inserts).- Dynamic balance: G0.4 (to avoid insert chipping from vibration).

|

Provide rotational power; ensure stable cutting speed.

|

|

Servo Feed System

|

– Positioning accuracy: ±0.001 mm.- Feed rate range: 0.01-2000 mm/min (adjustable based on insert wear status).

|

Drive tool movement; match feed rate with insert cutting performance.

|

|

Tool Condition Monitoring (TCM)

|

– Sensors: Piezoelectric force sensors (measure cutting force, resolution 0.1 N); Thermocouples (monitor cutting zone temp, resolution 1°C).

|

Real-time detect insert wear (wear threshold: 0.3 mm for flank wear) or breakage.

|

(2) Insert Cooling and Chip Evacuation Design

- High-pressure coolant system: Delivers coolant (emulsion or oil) to the cutting edge via a tool holder’s internal channel, with a nozzle positioned 1-2 mm from the insert’s rake face. This reduces cutting zone temperature by 30%-50% (from 800°C to 400-560°C) and prevents chip adhesion to the insert (critical for machining stainless steel, e.g., 304).

- Chip breaker optimization: For ductile materials (e.g., aluminum alloy), use inserts with “wide groove + shallow rake angle” chip breakers to produce short spiral chips; for brittle materials (e.g., cast iron), use “narrow groove + steep rake angle” designs to avoid powdery chip accumulation.

3. Core Control Algorithms for Insert CNC Turning

(1) Tool Path and Cutting Parameter Optimization

- Tool nose radius compensation (G41/G42):

- Adaptive cutting parameter adjustment:

-

- When insert flank wear reaches 0.2 mm (50% of the threshold), reduce feed rate by 10%-15% to extend tool life.

-

- For workpiece material hardness variations (e.g., 45# steel with hardness 180-220 HB), adjust cutting speed: 180 HB → 250 m/min; 220 HB → 220 m/min (to maintain stable cutting force ≤ 3 kN).

(2) Insert Life Prediction and Management

- Empirical life model:

-

- Carbide insert (WC-Co) machining 45# steel: n=0.25, C=600 → V=200 m/min → T=120 min; V=250 m/min → T=65 min.

- AI-based life prediction:

4. Precision Detection and Calibration Technology

(1) Insert Installation Precision Calibration

- Pre-setting with tool presetter:

-

- Radial runout of the insert cutting edge: ≤ 0.005 mm.

-

- Axial (end) runout: ≤ 0.003 mm.

- On-machine verification:

(2) Spindle and Feed Axis Calibration for Insert Cutting

- Spindle speed accuracy calibration:

- Feed axis backlash compensation:

5. Typical Process Difficulties and Technical Breakthroughs

(1) Machining of Sticky Materials (e.g., 304 Stainless Steel)

- Select inserts with TiAlN-AlCrN composite coating (reduces friction coefficient to 0.2).

- Use high-pressure coolant (10 MPa) to flush chips away from the cutting edge.

- Optimize cutting parameters: V=120-150 m/min, f=0.1-0.15 mm/r (avoids low speed-induced BUE).

(2) High-speed Turning of Thin-walled Workpieces (e.g., Aluminum Alloy Cylinders, Wall Thickness 0.5-1 mm)

- Use inserts with small nose radius (rₑ=0.2 mm) and sharp cutting edge (rake angle γₒ=15°) to reduce radial cutting force (≤ 500 N).

- Adopt a “light-cutting” strategy: depth of cut aₚ=0.1-0.2 mm, multi-pass machining (3-4 passes) instead of single-pass heavy cutting.

- Mount the workpiece on a hydraulic chuck with soft jaws (hardness HRC20) to distribute clamping force evenly.

(3) Turning of Hardened Steel (e.g., 40Cr, HRC 50-55)

- Use CBN (cubic boron nitride) inserts (thermal conductivity 130 W/m·K, 3x higher than carbide).

- Implement dry cutting (avoid coolant-induced thermal shock to CBN inserts) with V=80-120 m/min, f=0.08-0.1 mm/r.

- Use a rigid tool holder (CAPTO C6) to minimize vibration (acceleration ≤ 0.3 g).

6. Common Issues and Troubleshooting

(1) Premature Insert Wear

- Cutting speed too high (e.g., carbide insert machining steel at V=300 m/min, exceeding its thermal limit).

- Coolant flow insufficient (nozzle blocked, flow rate < 5 L/min).

- Reduce cutting speed by 20%-30% (refer to the insert manufacturer’s recommended parameter table).

- Clean the coolant nozzle and check the pump pressure (ensure ≥ 5 MPa).

(2) Insert Chipping

- Insert clamping force too low (screw torque < 5 N·m, leading to insert movement).

- Spindle dynamic balance error (G2.5 instead of G0.4, causing vibration).

- Tighten the insert screw to the specified torque (use a torque wrench).

- Recalibrate the spindle dynamic balance (add counterweights to reduce vibration amplitude to ≤ 0.1 mm/s).