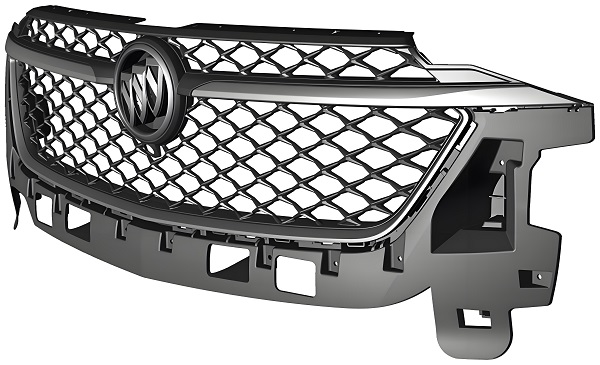

In the wave of automobile personalization and performance enhancement, custom car air intake grille has become the first choice of many car owners in pursuit of unique style and excellent performance. As an important part of a vehicle’s front face, the air intake grille not only affects the aesthetics of the vehicle, but also directly relates to the engine’s air intake efficiency and cooling performance. The following is a comprehensive introduction to customized automotive air intake grilles.

1. Automotive air intake grille production process

Design planning: According to the customer’s demand and model data, the professional designer will carry out the preliminary design of the air intake grille, including the style, size, aperture rate and so on.

Material preparation: select suitable materials according to the design program and conduct quality inspection to ensure that the materials meet the production standards.

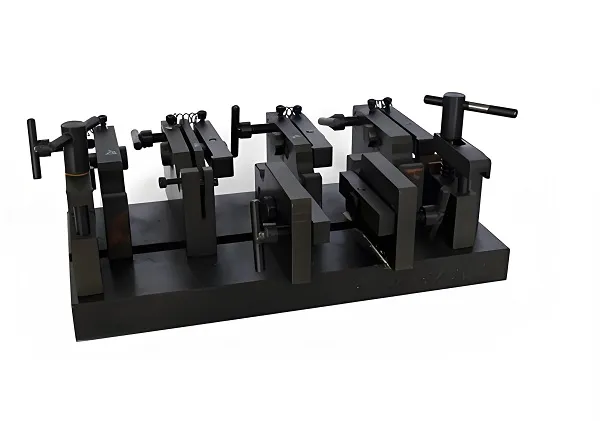

Mold making: Make accurate molds according to the design drawings, which is a key step to ensure the accuracy of the product.

Forming Processing: Use the mold to form the basic shape of the air intake grille by stamping, injection molding or casting the material.

Surface treatment: carry out polishing, spraying, plating and other surface treatment processes to enhance the appearance of the product texture and corrosion resistance.

Assembling and quality inspection: assembling the parts into a complete air intake grille and carrying out strict quality inspection to ensure that the product is flawless.

Packing and shipping: Pack the finished products properly to prevent damage during transportation, and arrange shipping to the customer’s designated location.

2. Processing steps for automobile air intake grille

Cutting: Use high-precision cutting equipment to cut the raw material accurately.

Bending/Stamping: The material is processed into preset complex shapes by bending or stamping machines.

Welding/Assembly: The parts are firmly connected by welding or screwing.

Grinding: Remove burrs and uneven parts generated during processing to improve surface smoothness.

Painting/Electroplating: Apply surface treatment according to design requirements to enhance visual effect and durability.

3. Customized automotive air intake grille service

One-on-one design service: Provide personalized design solutions according to customer needs to ensure that the air intake grille matches the vehicle perfectly.

Multiple material choices: Provide multiple material options to meet the performance and appearance needs of different customers.

Rapid sampling and confirmation: quickly make samples for customers to confirm, to ensure the accuracy of the design.

Professional installation guide: Provide detailed installation guide or optional installation service to ensure smooth installation process.

After-sales guarantee: provide perfect after-sales service to solve any problems encountered by customers in the process of use.

4. Introduction of automobile air intake grille material

ABS plastic: lightweight, easy to process, low cost, suitable for customers pursuing cost-effective.

Characteristics: impact resistance, easy to shape, colorful.

Aluminum alloy: high strength, corrosion resistance, good heat dissipation, preferred for high performance vehicles.

Characteristics: lightweight, strong, good thermal conductivity.

Carbon Fiber: Extreme lightweight, high strength, high temperature resistance, suitable for racing and high-end modifications.

Characteristics: light weight, high strength, high temperature resistance, corrosion resistance.

Stainless steel: strong durability, good appearance and texture, suitable for the pursuit of long-term durability and aesthetic customers.

Characteristics: corrosion-resistant, easy to clean, beautiful and generous.

5. Characteristics of different materials of automobile air intake grille

ABS plastic air intake grille:

● Weight reduction of about 30%, cost reduction of about 20%.

●Impact strength reaches ISO standard, and the color stays bright for a long time.

Aluminum air intake grille:

●The heat dissipation efficiency is increased by 15%, and the strength is 3 times higher than steel of the same volume.

●Superior corrosion resistance, no visible oxidation marks after long-term use.

Carbon fiber air intake grille:

●Weight is only 1/4 of metal parts of the same size, and strength is increased by more than 2 times.

●High temperature resistance up to 300°C, maintaining structural stability without deformation.

Stainless steel air intake grille:

●Corrosion resistance level reaches 304/316 standard, with a service life of more than 10 years.

●Surface as smooth as a mirror, easy to clean and maintain.

Customized Automotive Air Intake Grille Service FAQ

Q: How long does it take to customize the air intake grille?

A: Typically, it takes about 2-4 weeks from design confirmation to finished product shipment, depending on material selection and processing complexity.

Q: Do I need a professional technician to install the air intake grille?

A: Although some vehicle owners can install the grille themselves, it is recommended to have it installed by a professional technician to ensure the accuracy and safety of the installation.

Q: Will a custom air intake grille affect the performance of my vehicle?

A: Customized air intake grilles are designed with aerodynamics in mind, and not only will they not degrade performance, but they may improve engine air intake efficiency and cooling performance.

Q: What does the after-sales service include?

A: The after-sales service includes free repair, replacement and technical consultation during the warranty period to ensure that customers can use the products without worry.