I. Technological Dimension: The Integration of Intelligence and Precision

Modern auto sun visors have long gone beyond the simple function of a “sun – blocking panel.” With infrared – sensing error – prevention technology, the assembly position of the pivot can be detected in real – time to avoid human errors. The intelligent light – sensing adjustment technology can automatically adjust the light transmittance according to the intensity of sunlight, not only without blocking the line of sight but also preventing glare.

Leading companies in the industry, have also introduced sliding force detection technology. By using customized equipment to simulate 6,000 sliding cycles, it ensures that the sun visor has a smooth push – pull feel and the force is stable at 6N ± 2N. These technologies have upgraded the sun visor from “passive blocking” to “active protection.”

II. Material Dimension: The Evolution from PVC to Aerospace – grade Composites

Surface Materials

PVC and Knitted Fabrics: Traditional PVC is wear – resistant but has poor breathability. Knitted fabrics are softer and more suitable for the interior style of luxury cars.

Double – coated Flame – retardant Material: The first choice for high – end customization. One side is silver – colored to reflect ultraviolet rays, and the other side has a customized pattern for scratch – resistance. Its flame – retardant performance meets the UL94 standard.

Skeleton Materials

EPP Foam Material: The first choice for lightweighting, with a 30% weight reduction compared to traditional PP materials and improved energy – absorption effect.

Glass – fiber Reinforced Polyurethane: Used for racing – grade sun visors, it can withstand high temperatures of up to 150℃.

III. Production Process: Nine Procedures to Create Perfect Quality

Design and Modeling: 3D – scan the interior space of the car to ensure that the sun visor does not interfere with the ceiling and rear – view mirror.

Material Pretreatment: Double – coated fabrics need to be aged at a constant temperature for 24 hours to avoid bubble problems in the thermonuclear process.

Mold Molding: The low – pressure injection molding process is used, and the error of the EPP skeleton is controlled within ±0.2mm.

Intelligent Assembly: Robots automatically install the shaft spring plates, with a torque accuracy of 0.1N·m.

Function Testing: Includes sliding force, end – stop force, and VOC emission detection.

IV. Equipment and Processes: Hidden Hard – core Strength

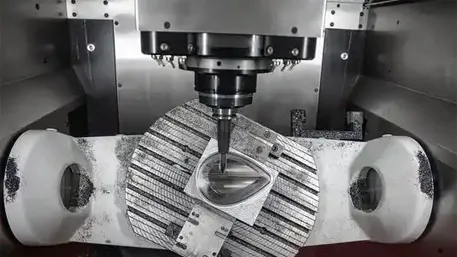

Five – axis CNC Machine Tool: Engraves complex – curved molds with micron – level accuracy.

High – frequency Welding Equipment: Completes the PVC joint welding in 0.1 seconds, with a strength 5 times higher than that of gluing.

Automatic Cutting Machine: Laser – positions and cuts fabrics, increasing the utilization rate to 98%.

Environmental Simulation Chamber: Conducts a 72 – hour cycle test under – 40℃ ~ 120℃ working conditions, simulating 10 – year aging.

V. Quality Control: Standards More Stringent Than Those of Automakers

In addition to the national standard QC/T629 – 2005, custom manufacturers also add:

Tactile Consistency Test: A blind – test group of 20 people evaluates the push – pull damping feeling.

Mirror Optical Test: The imaging distortion rate of the vanity mirror is less than 0.5%.

Environmental Certification: Complies with the EU REACH regulation, with a formaldehyde release amount of ≤0.01mg/m³.

VI. Cost and Pricing: The Secret of 300 yuan vs 3000 yuan

Material cost accounts for 40%: Double – coated flame – retardant materials are 3 times more expensive than single – coated ones, but their lifespan is extended by 5 years.

Mold Amortization: Modular design reduces the mold – opening cost from 500,000 yuan to 100,000 yuan.

Intelligent Premium: The cost of a sun visor with light – sensing adjustment function increases by 200 yuan, and the terminal premium can reach 800 yuan.

VII. Customization Services: Your Sun Visor is Unique

Functional Customization

Business Version: Integrates a wireless charging module.

Parent – child Version: Adds an IPAD bracket slot.

Appearance Customization

Laser – engrave license plate numbers.

Create a glow – in – the – dark starry – sky roof pattern.

Quick Response: The shortest delivery time from design to delivery is 7 days, and orders of 50 pieces or more are supported.

Frequently Asked Questions (FAQ)

Q1: Is it necessary to customize a sun visor for an ordinary car?

If the car is parked outdoors for a long time or has a leather/wood – veneer interior, customizing a double – coated flame – retardant sun visor can reduce the interior aging risk by 60%.

Q2: Will an intelligent sun visor affect the annual vehicle inspection?

The electric – adjustment version that has passed the 3C certification does not affect the inspection, but if you modify the photochromic glass, you need to file for record.

Q3: How to judge the quality of a sun visor?

One smell (no pungent odor), two pull, three check (check the light transmittance test report, which should be ≤5%).

Q4: Why does the custom price vary by 10 times?

Differences in materials, processes (manual edging vs robot welding), and functions (basic version vs intelligent sensing) lead to this.

Q5: Can the sun visor completely prevent the car from heating up?

Top – level products can block 90% of infrared rays, making the temperature inside the car 22℃ lower than that without using it after 4 hours of exposure to the sun, but it needs to be used in combination with leaving a gap in the car window.

Looking at the evolution of the automotive industry from a sun visor, customization is not only a demand for consumer upgrading but also a reflection of precision manufacturing capabilities. The next time you choose sun – shading accessories for your car, you might as well ask: “How many high – tech features are hidden in this panel?”