In the precise operation of automotive engines, pistons serve as critical “heart components” enduring extreme conditions, directly influencing engine power output, energy efficiency, and lifespan. With the technological evolution of new energy vehicles and high-performance engines, customized automotive piston parts have emerged as a key solution to break through the limitations of traditional standardized production, leveraging precise data matching and advanced manufacturing processes. This article dissects how customization reshapes the core competitiveness of piston manufacturing from the perspectives of technical advantages, quality control, and efficiency-cost balance.

1. Why is Customization the New Trend in Piston Manufacturing?

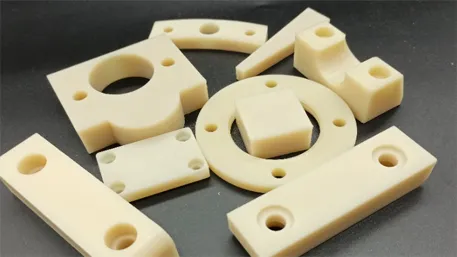

Standardized pistons often struggle with issues like insufficient heat dissipation and excessive wear under complex conditions such as turbocharging or hybrid systems. In contrast, custom pistons focus on “precise adaptation”:

- Deep Deep Operating Condition Matching: Tailored to engine displacement (1.5L/2.0T) and fuel type (gasoline/diesel/hybrid), key parameters are optimized—for example, hybrid pistons use corrosion-resistant hypereutectic aluminum-silicon alloys, with skirt profiles refined to an ellipticity of 0.15mm to reduce cold-start friction loss.

- Data-Driven Design: Thermal simulation software models stress distribution under maximum (18-25MPa), calculating pin bore tolerances (±0.002mm level) to eliminate knock risks caused by clearance errors from the design stage.

Case Evidence: A new energy vehicle manufacturer achieved a 3% increase in engine thermal efficiency and 5% reduction in energy consumption after adopting custom pistons, verifying the direct performance gains of customization.

2. How Core Technologies Achieve Precision Breakthroughs

1. 5-Axis Machining: One-Pass Machining for Complex Surfaces

Complex structures like elliptical piston skirts and variable-section ring grooves require 5-axis CNC machines for high-precision machining:

- Intelligent Tool Orientation Adjustment: Tilting the tool 15° via A/B axes ensures it remains perpendicular to the surface normal, controlling surface roughness below Ra0.8μm—50% higher precision than 3-axis machining.

- Full-Process Integrated Machining: A zero-point positioning system (repeatability ≤0.002mm) completes top surface, ring groove, and skirt machining in one setup, eliminating cumulative errors from multi-step clamping (reducing pin bore positional tolerance risks by 90%).

2. End-to-End Data Closed-Loop Control

Every stage from design to delivery is driven by data:

- Programming Phase: UG/CAM software generates tool paths while simulating cooling groove flow efficiency, optimizing spiral groove depth to ±0.05mm to avoid machining residues that affect heat dissipation.

- Machining Execution: Real-time collection of 30+ parameters (spindle speed 12,000rpm, feed rate 2,000mm/min) triggers automatic parameter adjustment when cutting force exceeds thresholds (e.g., 500N for titanium alloy), reducing tool breakage by 60%.

- Inspection Phase: CMM (Coordinate Measuring Machine) performs full-dimension scanning, uploading critical data (piston diameter tolerance ±0.01mm, top surface flatness 0.005mm) to the MES system for traceable digital records.

3. Quality Control: Full-Chain Protection from Material to Finished Product

1. Multi-Dimensional Inspection Standards

- Material-Level Strict Screening: Spectral analysis verifies aluminum alloy composition (12-13% silicon content), hardness testing (HB120-150) ensures wear resistance; X-ray flaw detection rejects blanks with internal pores >0.3mm in diameter.

- Finished Product Performance Validation:

-

- Seal Test: Leakage <5ml/min under 0.8MPa pressure prevents oil contamination from gas leakage.

-

- Thermal Stability Test: Simulating 300-500℃ cyclic conditions, skirt expansion is controlled within 0.05-0.1mm to ensure cylinder fit precision at high temperatures.

2. Intelligent Defect Prevention System

- First-Article Triple Inspection: Programmers, operators, and quality inspectors jointly verify 12 key dimensions (pin bore center distance ±0.015mm, ring groove spacing), intercepting batch deviations at the source.

- AI Visual Inspection: Linear array cameras complete surface scanning in 0.2 seconds, identifying scratches/deformations >0.1mm depth with a miss rate as low as 0.01%—meeting aerospace-grade inspection standards.

4. How Small-Batch Customization Balances Efficiency and Cost

Q: Does Custom Production Mean High Costs?

Three process innovations boost efficiency by 30% and reduce costs by 25%:

- Modular Process Design: A feature library for ring grooves, pin bores, and top surfaces reuses 80% of process parameters for similar parts, cutting programming time by 40% and avoiding repetitive development waste.

- Flexible Automation: Truss robots with quick-change chucks enable 2-minute model switching for multi-variety production, bringing small-batch (50-200 pieces) efficiency close to mass production levels.

- Intelligent Tool Management: IoT sensors monitor tool wear in real time, predicting a replacement cycle of 200 pieces per edge to avoid rework costs from overuse, increasing tool utilization by 40%.

5. Three Core Criteria for Choosing Custom Pistons

- Data Transparency: Suppliers should provide traceable files including machining parameters, inspection reports, and thermal simulation data to ensure quantifiable performance and problem traceability.

- Technical Adaptability: Capabilities in 5-axis machining, material heat treatment (e.g., T6 aging process), and computational fluid dynamics simulation are essential, especially for new energy vehicles requiring lightweight pistons (density ≤2.8g/cm³) and high thermal conductivity.

- Response Speed: A sample delivery cycle ≤15 days after drawing confirmation supports OEMs’ rapid prototyping and iteration, gaining a market edge.

Conclusion

The value of custom automotive pistons extends beyond mere “tailored dimensions”—it lies in achieving “lossless conversion” from design parameters to actual performance through data-driven full-chain optimization. As engine technology evolves toward higher efficiency and cleanliness, customized solutions with “precise data matching + advanced manufacturing processes” are becoming a must-have for automakers to build core engine competitiveness. Whether for performance breakthroughs in traditional ICE vehicles or technological innovation in new energy cars, custom pistons will leverage “millimeter-level precision” to unlock “engine-level performance,” enabling stable power output under the most demanding conditions.

(Contact us today to get your exclusive piston customization solution and free process consultation.)