Table of Contents

- Service Overview

- Material Technical Specifications

- Customization Process System

- Manufacturing Process Capabilities

- Quality Control Standards

- Application Field Cases

- Technical Service Advantages

- Contact & Cooperation

Service Overview

Core Service Capabilities

- 3D modeling and structural optimization

- Mold design and manufacturing

- Prototype production and testing verification

- High-precision injection molding

- Surface treatment processes

- Assembly and system integration

- Full-process quality monitoring

- Performance testing and verification

- After-sales service support

Industry Application Scope

- Sedan front and rear bumper assemblies

- SUV protection bar systems

- Commercial vehicle collision avoidance devices

- New energy vehicle special bumpers

- Modified vehicle personalized accessories

Material Technical Specifications

Engineering Plastic Material System

|

Material Type

|

Density(g/cm³)

|

Tensile Strength(MPa)

|

Impact Strength(kJ/m²)

|

Heat Distortion Temp.(℃)

|

Application Area

|

|

PP+EPDM-T20

|

1.02-1.08

|

35-45

|

40-60

|

140-160

|

Bumper main body

|

|

PP+EPDM-T30

|

1.08-1.15

|

45-55

|

30-50

|

150-170

|

Reinforcement rib structure

|

|

TPO

|

0.90-0.95

|

25-35

|

80-120

|

120-140

|

Flexible anti-collision strip

|

|

PC/ABS Alloy

|

1.10-1.15

|

50-65

|

25-40

|

110-130

|

Decorative panel

|

|

PA6+GF30

|

1.35-1.40

|

130-150

|

15-25

|

200-220

|

Bracket connectors

|

Material Performance Characteristics

- Excellent toughness: Maintains good toughness in temperature range of -40℃ to 80℃

- Weather resistance: UV aging resistant, service life up to 8 years

- Lightweight: 40-60% weight reduction compared to metal materials

- Cost-effective: Good cost-performance ratio, suitable for mass production

- Soft touch: Shore A hardness 60-80, providing comfortable tactile experience

- Impact resistance: Excellent low-temperature impact strength, effectively absorbs collision energy

- Color stability: Easy to color, long-lasting color stability

Environmental Compliance Requirements

- RoHS Directive: Restriction of hazardous substances

- REACH Regulation: Chemical safety assessment compliance

- ELV Directive: Vehicle recycling rate ≥95%

- VOC Emissions: Volatile organic compound emissions meet national standards

Customization Process System

Requirements Analysis Phase

- In-depth understanding of customer specific needs and technical requirements

- Analysis of product usage environment and performance indicators

- Assessment of project feasibility and cost budget

- Material selection recommendations and performance verification

- Structural design optimization and process feasibility analysis

- Cost estimation and delivery cycle evaluation

Design and Development Phase

- 3D modeling using professional software such as CATIA and UG

- Structural strength analysis and collision simulation

- Design scheme optimization to ensure manufacturing feasibility

- Mold design using CAD/CAM technology

- Mold manufacturing using high-precision processing equipment

- Mold trial and optimization adjustments

Prototype Verification Phase

- Rapid prototype production to verify design concepts

- Appearance and dimensional inspection

- Assembly testing and functional verification

- Impact strength testing (GB/T 1043.1)

- Bending strength testing (GB/T 9341)

- Heat distortion temperature testing (GB/T 1634.2)

- Weather resistance testing (GB/T 16422.2)

Mass Production Phase

- Production process parameter optimization

- Quality control standard formulation

- Production equipment debugging and personnel training

- Strict implementation of production according to process documents

- Real-time monitoring of production process and quality status

- Regular process inspection and product sampling inspection

Manufacturing Process Capabilities

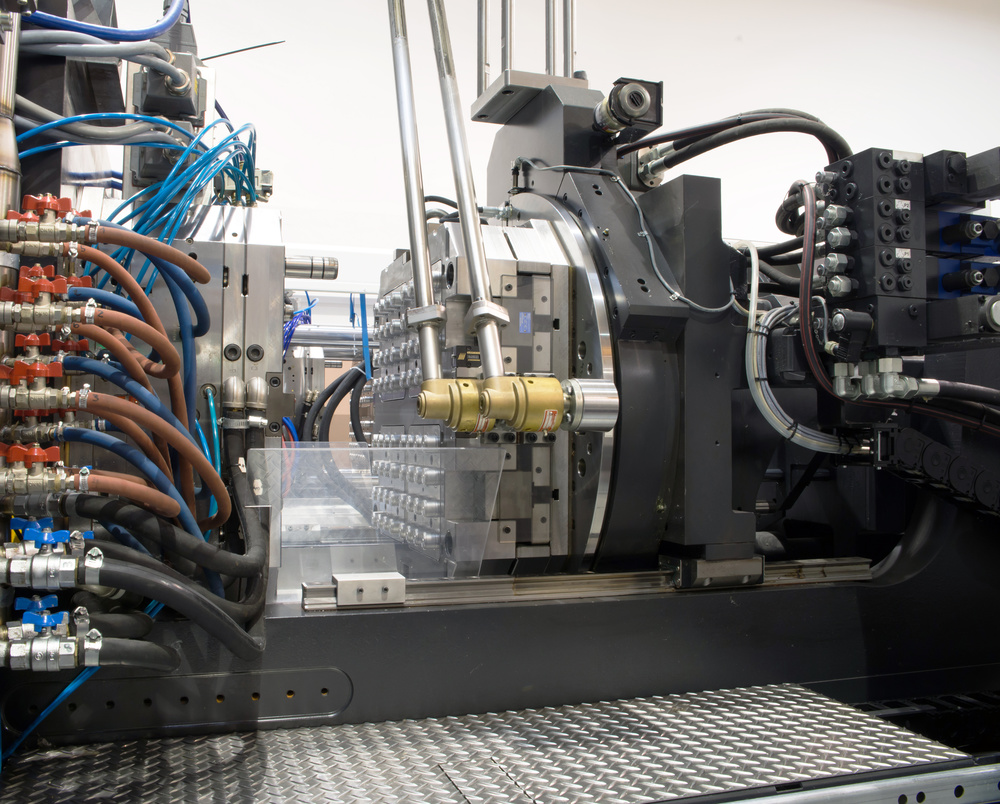

Injection Molding Technology

|

Equipment Specification

|

Clamping Force(Ton)

|

Injection Capacity(cm³)

|

Max Product Weight(kg)

|

Applicable Products

|

|

Small Machine

|

160-350

|

100-500

|

0.5-2.0

|

Small accessories

|

|

Medium Machine

|

400-800

|

500-2000

|

2.0-8.0

|

Bumper main body

|

|

Large Machine

|

1000-2000

|

2000-5000

|

8.0-20.0

|

Large bumper assemblies

|

- Gas-assisted injection: Reduces product warpage, shortens cooling time by 20-30%

- Two-color injection: Achieves integrated molding of different materials and colors

- Precision injection: Dimensional tolerance controlled within ±0.05mm

Surface Treatment Processes

- Electrostatic spraying: Uniform coating thickness, strong adhesion

- UV curing: Rapid curing, improves production efficiency

- Vacuum coating: Achieves metallic texture effect

- Chemical etching: Fine texture, enhances appearance quality

- Laser engraving: High-precision pattern and logo production

- In-mold decoration: Integrated molding, reduces subsequent processes

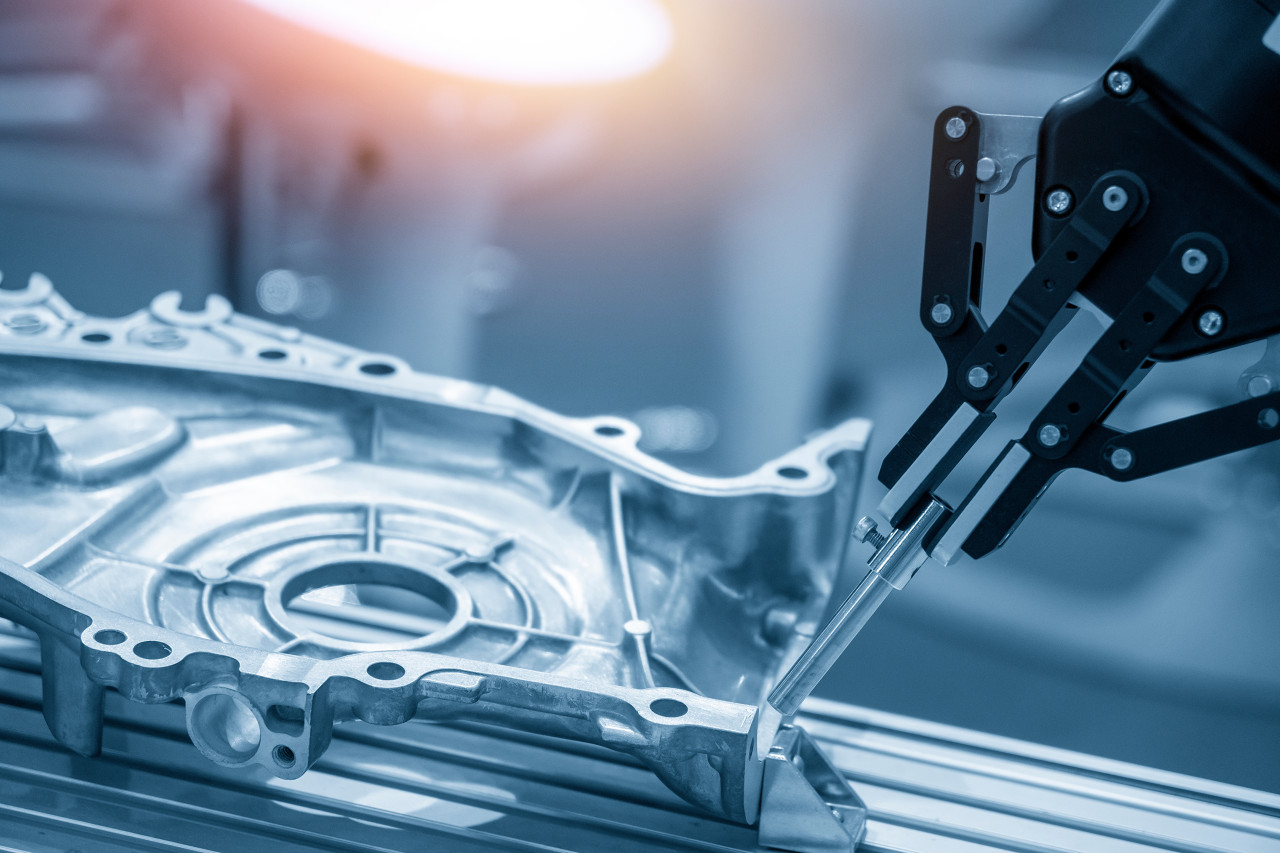

Assembly and Integration Capabilities

- Robotic automatic assembly systems

- Online inspection and quality control

- Flexible production, quick changeover

- Electrical system integration

- Sensor installation and debugging

- Overall performance test verification

Quality Control Standards

Quality Management System

- ISO 9001: Quality management system certification

- IATF 16949: Automotive industry quality management system

- ISO 14001: Environmental management system certification

- OHSAS 18001: Occupational health and safety management system

Testing Equipment Configuration

- Coordinate measuring machine: Measurement accuracy ±0.001mm, ensuring product dimensional accuracy

- Projector: 2D dimensional measurement, accuracy ±0.002mm

- Height gauge: Height and depth measurement, accuracy ±0.001mm

- Universal testing machine: Tensile, bending, compression strength testing

- Impact testing machine: Room temperature and low-temperature impact strength testing

- Heat distortion tester: Heat distortion temperature and Vicat softening point testing

- Colorimeter: Color deviation detection, ΔE≤0.8

- High-low temperature test chamber: -40℃ to 150℃ temperature cycle testing

- Humidity test chamber: Temperature and humidity environment simulation testing

- UV aging test chamber: UV aging acceleration testing

- Salt spray test chamber: Corrosion resistance testing

Quality Control Process

- Raw material quality certificate verification

- Material performance sampling testing

- Appearance and dimensional inspection

- First article inspection confirmation

- Production process patrol inspection

- Key process control point monitoring

- Comprehensive appearance quality inspection

- Dimensional accuracy testing

- Performance test verification

- Final product inspection confirmation

- Packaging integrity inspection

- Quality document preparation

Quality Standard Requirements

- Critical dimensions: ±0.05mm

- Important dimensions: ±0.10mm

- General dimensions: ±0.20mm

- Surface defects: No scratches, bubbles, flash or other defects

- Color consistency: ΔE≤1.0

- Glossiness: Deviation within ±5%

- Impact strength: ≥30kJ/m² (-40℃)

- Bending strength: ≥40MPa

- Heat resistance: No deformation at 120℃×1h

- Weather resistance: No obvious changes after 1000h xenon lamp aging

Passenger Vehicle Field

- Application models: Compact cars, mid-size cars, luxury cars

- Product features: Lightweight design, excellent collision energy absorption performance

- Technical highlights: PP+EPDM-T20 material, integrated radar mounting bracket

- Application models: Urban SUVs, off-road SUVs

- Product features: High-strength structure, enhanced protection capability

- Technical highlights: Modular design, easy maintenance and replacement

Commercial Vehicle Field

- Application models: Light trucks, medium trucks, heavy trucks

- Product features: High strength, impact resistance, corrosion resistance

- Technical highlights: PA6+GF30 material, long service life

- Application models: City buses, long-distance buses, tourist coaches

- Product features: Safety standard compliance, pedestrian protection

- Technical highlights: Integrated LED daytime running lights and camera mounting positions

New Energy Vehicle Field

- Application models: Pure electric vehicles, hybrid vehicles

- Product features: Lightweight design, optimized aerodynamics

- Technical highlights: Integrated charging port cover and sensor module

- Application products: Radar mounting brackets, camera shields

- Product features: High-precision installation, no signal transmission interference

- Technical highlights: PC/ABS material, excellent weather resistance

Modified Vehicle Field

- Product types: Sports bumpers, decorative surrounds

- Product features: Personalized design, enhanced appearance quality

- Technical highlights: TPO material, customizable colors and textures according to customer requirements

Technical R&D Advantages

- Engineering team with over 15 years of automotive accessory design experience

- Familiar with design standards and specifications of major automakers

- Complete vehicle matching and system integration capabilities

- Structural strength simulation analysis using ANSYS

- Collision performance simulation using LS-DYNA

- Injection molding process simulation using Moldflow

Manufacturing Capability Advantages

- Imported high-precision equipment from Germany, Japan, etc.

- Equipped with automated production lines to improve production efficiency

- In-house mold manufacturing capabilities to shorten development cycles

- Rich experience in automotive bumper production

- Mastery of molding processes for various complex structures

- Large-scale mass production capabilities

Quality Assurance Advantages

- Whole-process quality control from raw materials to finished products

- Established comprehensive quality traceability system

- Strict implementation of IATF 16949 quality management standards

- Complete product performance testing equipment

- Product reliability and durability testing capabilities

- Ability to conduct various tests according to international standards

Service Response Advantages

- 24-hour customer demand response

- Technical solution provision within 48 hours

- Prototype production completion within 72 hours

- Comprehensive technical consulting services

- Assistance in product design optimization for customers

- Installation and commissioning guidance for customers

- Established comprehensive after-sales service system

- Rapid handling of product quality issues

- Regular customer follow-up visits, continuous service quality improvement

Contact & Cooperation

Contact Information

Quick Quotation Process

- Product drawings or samples

- Material and performance requirements

- Quantity and delivery time

- Special process requirements

- Feasibility analysis

- Process scheme development

- Cost estimation

- Delivery time assessment

- Detailed quotation sheet

- Technical scheme description

- Quality standard commitment

- Service guarantee terms

Cooperation Models

- Production according to customer design requirements

- Complete manufacturing services

- Customer brand packaging support

- Product design and development

- Technical scheme optimization

- Intellectual property protection

- Long-term cooperation agreements

- Joint technology development

- Market resource sharing

Quality Commitment

- Product qualification rate: ≥ 99.5%

- On-time delivery rate: ≥ 98%

- Customer satisfaction rate: ≥ 95%

- Quality complaint response: Within 24 hours