Custom brass forged pipe connectors are specialized fluid-transmission components made via forging processes (hot/cold forging) with brass. They integrate brass’s corrosion resistance and ductility with forging-enhanced strength (tensile strength ≥350MPa), mainly used to connect pipes (copper, steel, plastic) in fluid systems. Tailored to pipe diameters (DN15-DN100), pressure requirements (1.6-10MPa), and media types (water, oil, chemicals), they ensure leak-proof sealing and stable flow, widely applied in building plumbing, industrial fluid lines, and HVAC systems.

1. Definition of Custom Brass Forged Pipe Connectors

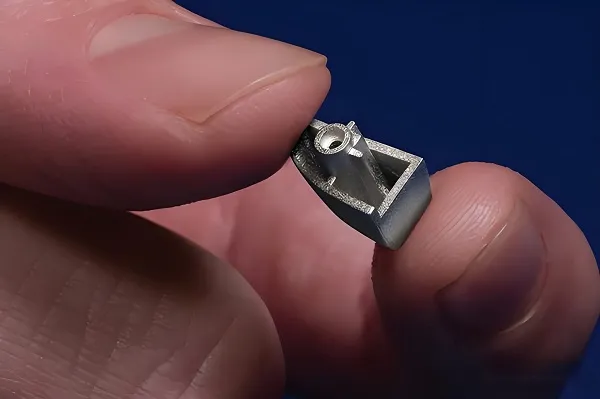

Custom brass forged pipe connectors refer to brass-based components designed for pipe assembly, manufactured via forging (not casting) to optimize material density. Unlike standard cast connectors, they feature:

- Forging-specific advantages: Grain refinement from forging reduces internal defects, improving pressure resistance by 20-30% vs. cast variants;

- Customization core: Tailored to pipe size (e.g., ½”-4″ nominal diameter), connection type (threaded, welded, press-fit), and sealing structure (O-ring, taper seal);

- Performance benchmarks: Compliance with standards like ASME B16.15 (small forged fittings) or ISO 4144 (brass pipe fittings), ensuring compatibility with global pipe systems.

2. Materials for Custom Brass Forged Pipe Connectors

Material selection is based on fluid media, pressure, and temperature, with mainstream brass grades:

- H62 Brass (62% Cu): Balanced strength (≥300MPa) and cost-effectiveness, suitable for low-to-medium pressure systems (1.6-4MPa) like residential plumbing (water supply);

- H65 Brass (65% Cu): Superior ductility and forgeability, ideal for complex-shaped connectors (e.g., 3-way, elbow forged connectors) requiring precise sealing surfaces;

- Hpb59-1 Brass (59% Cu, 1% Pb): Excellent machinability post-forging, easy to process high-precision threads (NPT/BSP) for industrial pipe lines (oil/gas transmission);

- HSn70-1 Brass (70% Cu, 1% Sn): Enhanced corrosion resistance to chemicals (e.g., dilute acids, salts), suitable for marine or chemical industry fluid systems.

3. Functions of Custom Brass Forged Pipe Connectors

In fluid transmission systems, they fulfill four critical roles:

- Leak-Proof Connection: Forged sealing surfaces (Ra ≤0.8μm) and customized gaskets/O-rings prevent fluid leakage (leak rate <0.1mL/min at rated pressure);

- Pressure & Temperature Adaptation: Withstand operating pressures up to 10MPa and temperatures -20℃ to 120℃ (higher temp grades available for 150℃+ via material modification);

- Media Compatibility: Resist corrosion from common fluids—tap water (no rusting), mineral oil (no swelling), and mild chemicals (no material degradation);

- System Flexibility: Custom designs (e.g., reducing connectors for pipe size transitions, swivel connectors for angular adjustment) optimize pipe layout efficiency.

4. Processes for Custom Brass Forged Pipe Connectors

The forging-centric process chain ensures strength and precision, with 5 core steps:

- Pretreatment:

- Material preparation: Cutting brass rods into billets (weight tolerance ±2%) to match connector size;

- Heating (for hot forging): Heating billets to 800-950℃ (H65 brass) to improve malleability, avoiding overheating (>1000℃) which degrades material;

- Forging Process:

- Hot forging: Using hydraulic presses (500-1000 tons) to shape billets into rough connector forms (e.g., elbow, tee), enhancing material density by 15%;

- Cold forging (for precision parts): Applying room-temperature pressure (1200-1500 tons) for connectors with tight tolerances (±0.05mm), skipping annealing post-forging;

- Finishing:

- Trimming: Removing forging flash (excess material) via CNC trimming machines;

- Machining: Cutting threads (NPT/BSP) and refining sealing surfaces (CNC turning, Ra ≤0.8μm);

- Surface Treatment: Electroplating (nickel/chrome, thickness 8-12μm) for corrosion resistance, or passivation (clear coating) for aesthetic applications;

- Inspection:

- Dimensional check: CMM measurement of thread accuracy and fitting size;

- Pressure testing: Hydrostatic testing at 1.5x rated pressure (e.g., 6MPa for 4MPa connectors) for 30 minutes, no leakage allowed;

- Material verification: Spectrometric analysis to confirm brass grade compliance.

5. Machining of Custom Brass Forged Pipe Connectors

Post-forging machining focuses on “sealing precision” and “custom adaptability”:

- Thread Machining: Using CNC thread lathes to cut standard (NPT, BSP) or custom threads (e.g., metric M20×1.5), ensuring thread fit class (6g/7H) for leak-proof connection;

- Sealing Surface Processing: CNC grinding for flat sealing surfaces (parallelism ≤0.02mm) or taper turning for cone seals (taper tolerance ±0.01mm);

- Custom Modifications:

- Drilling auxiliary holes (e.g., pressure sensor ports) for industrial connectors;

- Chamfering pipe ends (45°/30°) to prevent pipe damage during assembly;

- Batch Flexibility: Small batches (50-200 pieces) use flexible CNC workstations; large batches (1000+ pieces) integrate forging-machining automated lines (output 500+ pieces/day).

6. Advantages of Custom Brass Forged Pipe Connectors

vs. cast brass, stainless steel, or plastic connectors, their core advantages:

- Superior Strength & Durability: Forging eliminates internal pores, making them 20-30% more pressure-resistant than cast brass; service life ≥15 years (vs. 8-10 years for plastic);

- Reliable Sealing: Brass’s ductility allows sealing surfaces to deform slightly under pressure, improving leak resistance vs. rigid stainless steel (leak rate 50% lower);

- Cost-Effectiveness: Brass costs 30-40% less than stainless steel; forging reduces material waste (scrap rate <3% vs. 8% for casting);

- Custom Versatility: Forging supports complex shapes (e.g., multi-port connectors, eccentric reducers) that are hard to achieve with casting; quick adaptation to non-standard pipe sizes.

7. FAQ about Custom Brass Forged Pipe Connectors

- Q: What’s the maximum pressure rating for your custom connectors?

A: Up to 10MPa for H65 brass (hot-forged); for higher pressure (15MPa), we recommend HSn70-1 brass with cold forging. - Q: Can they be used for food-grade fluid systems (e.g., beverage pipelines)?

A: Yes—we use lead-free H65 brass (Pb <0.01%) compliant with FDA 21 CFR §175.300, with passivation treatment to avoid metal ion leaching. - Q: What parameters do I need to provide for customization?

A: Pipe diameter (nominal/inner), rated pressure, fluid media, connection type (threaded/welded), and special features (e.g., swivel, sensor ports). - Q: How long does custom sample production take?

A: 3-5 days for standard shapes (elbow/tee); 5-7 days for complex custom designs (multi-port connectors).

8. Customization of Custom Brass Forged Pipe Connectors

We offer end-to-end customization tailored to fluid system needs:

- Demand Consultation: Our engineers analyze your system (pressure, media, pipe material) to recommend brass grade (e.g., Hpb59-1 for oil lines) and forging method (hot/cold);

- Design & Quotation: Deliver 3D models (STEP/IGES) and process plans within 2 days, clarifying cost (e.g., DN50 elbow connectors: $2.5-$4.0/piece) and lead time;

- Sample Production & Testing: Manufacture samples, conduct pressure/sealing tests, and send test reports—free sample revisions if specs don’t match;

- Mass Production & Delivery: Small batches (50-500 pieces) delivered in 7-10 days; large batches (1000+ pieces) in 12-15 days, with traceable batch numbers;

- After-Sales Support: 1-year warranty—if connectors leak due to manufacturing defects, we provide free replacements and on-site technical support.

If you need custom brass forged pipe connectors for plumbing, industrial fluid lines, or HVAC systems—whether for standard pipe sizes or special designs (e.g., high-pressure, food-grade)—please leave a message! With 12 years of brass forging experience, our products meet ASME/ISO standards, and we offer free sample testing. Let’s create leak-proof, durable pipe connection solutions that fit your system perfectly!